10/25

INSTALLATION

4.1 Unpacking and preparation

Prior to dispatch, the air heater was operated and

tested at the factory. If the heater has incurred any

damage in shipment, file a report claim within 2

working days from receipt.

Check the shipping label and data plate to ensure

the specification of gas and electrical supplies are

compatible. Read this document and become

familiar with the installation requirements and the

appliance before commencing installation.

4.2 Suspending the air heater

Before installing the appliance, check to ensure that

the supporting structure is adequate to carry the

weight of the appliance and its ancillaries i.e. flue

system.

Table 7 Approximate Net weights (kg)

LCSA-4

12

20

30

35

45

50

60

75

100

120

145

Weight 59

64

94

99

114

126

184

242

279

When the heater is lifted for suspension, support the

bottom of the heater with plywood or other

appropriately placed material. If the bottom is not

supported, damage could occur.

The heater is supplied with four point suspension.

All points must be used. Two threaded nut retainers

are provided on each side of the top of the heater.

See dimensions in section 2.2 and figure 3.

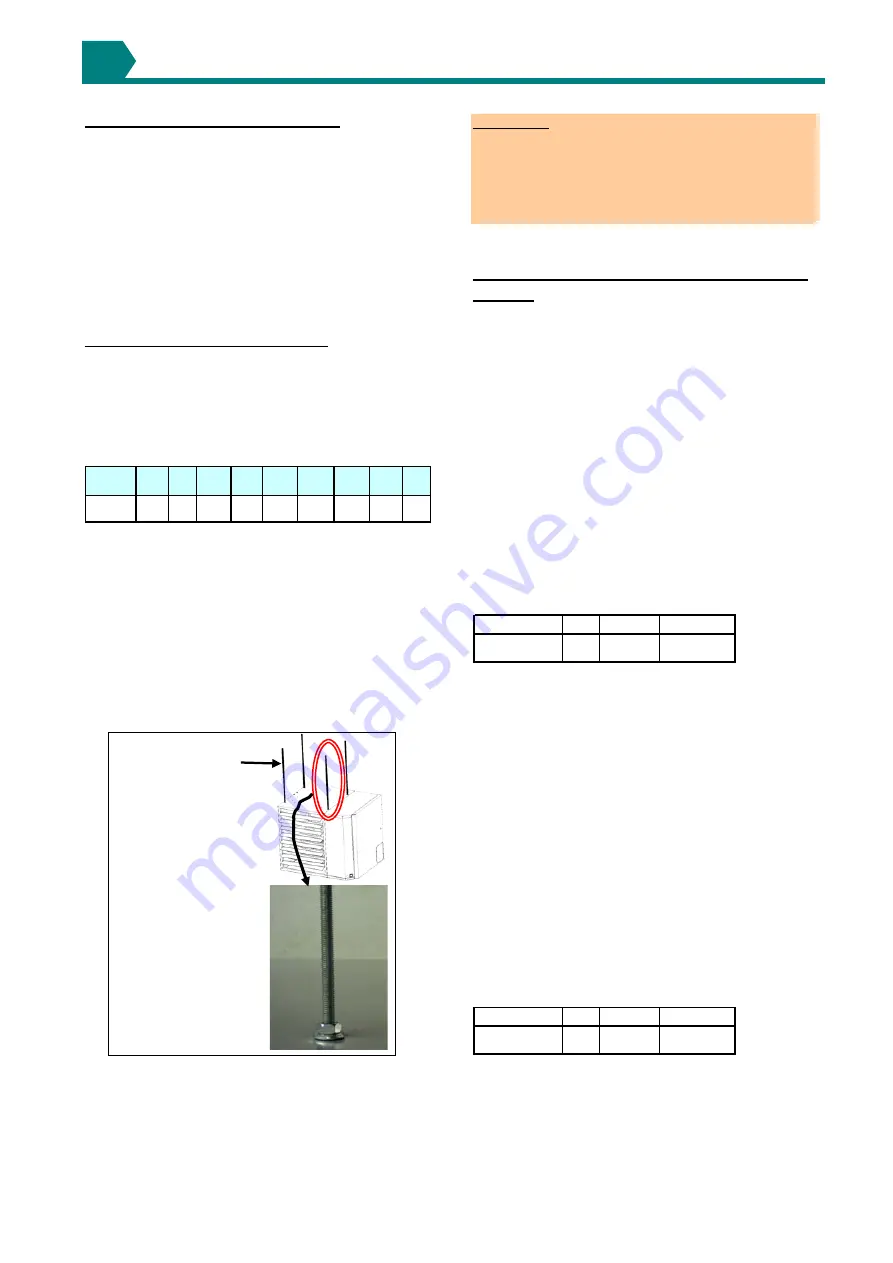

Figure 3 Suspension detail

Add a nut to lock the

M10x1.5 hanger rod to

the heater

Be sure that the threaded hanger rods are locked to the

heater as illustrated. Recommended maximum hanger

rod length is 1.8m.

IMPORTANT:

Suspend the heater from the threaded nut retainers. Do

not suspend from the heater cabinet panels.

Do not place or add additional weight to the suspended

air heater. See hazard levels, page 2.

The heater must be installed in a level plane to ensure

proper operation.

4.3 Fitting the Combustion air inlet/Flue

system

Flue pipe runs may be horizontal or vertical and

terminate either through the wall or roof. See table 5

for maximum pipe length for an appliance installed

as type B or table 6 for maximum lengths and

approved supplied concentric terminals for a heater

installed as a type C appliance.

All pipe runs must be independently supported so

that the heater does not carry any of the weight of

the flue system.

4.3.1 Fitting the flue pipe

The flue pipe socket is located on the back of the air

heater.

Flue pipes must be sealed. Use seamless,

aluminium pipe or equivalent. Follow pipe

manufacturer's instructions (see figures 4 & 5).

Table 8 Flue pipe socket size (dia mm)

12

20,30

35 -> 145

80

100

130

LCSA-4

Socket

4.3.2 Installing a guard on the combustion air

inlet pipe for power vent (Type B installations)

The combustion air inlet socket is located at the

back of the heater. When installed as a type B

appliance, protect the inlet by fitting an access

guard on the socket.

Do not block this socket as it

supplies combustion air for the burner (see

figure 4).

4.3.3 Fitting the combustion air inlet pipe for

balanced flue (Type C installations)

The combustion air pipe attaches directly to the inlet

socket at the back of the heater. Air inlet pipes must

be sealed. Use seamless aluminium or equivalent.

Follow the pipe manufacturer's installation

instructions. See typical installations in figure 5.

Table 9 Air inlet socket size (dia mm)

12

20,30

35 -> 145

80

100

130

LCSA-4

Socket

4