Form I-XE/CRGB/RPB, Mfg No. 131782 Rev 4, Page 11

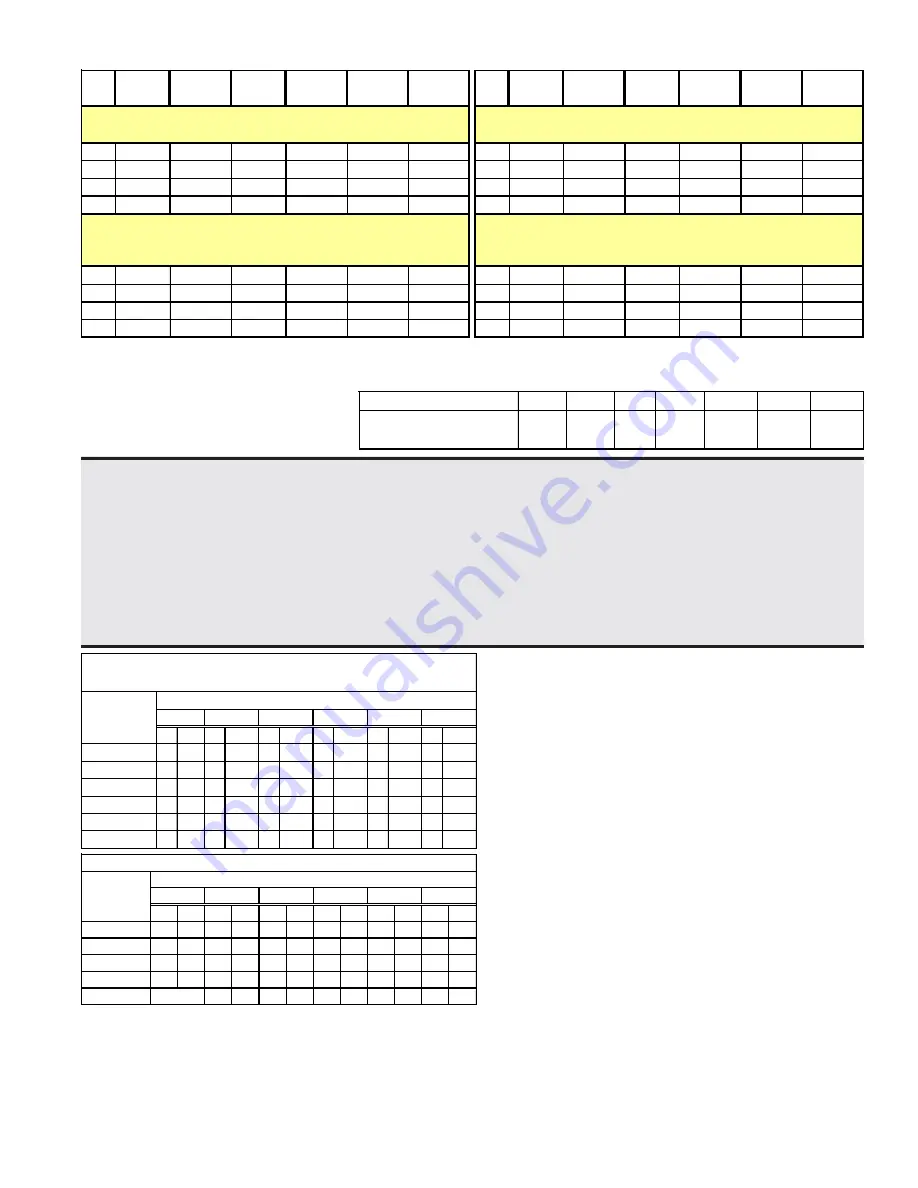

Roof Curb Dimensions (mm)

8. Venting

8A. Gravity-Vented

Indoor Models

XE/HXE

DANGER: Failure to provide proper venting could result in death, serious injury, and/or property damage. This

furnace must be installed with a vent connection and proper vent to the outside of the building. Install vent in

accordance with Part 7, Venting of Equipment, of the National Fuel Gas Code, ANSI Z223.1 (latest edition) or

applicable provision of national, state or local codes. A Canadian installation must be in accordance with the

CSA B149.1 and B149.2, Installation Code for Gas Burning Appliances and Equipment, and applicable local

codes. Also, follow venting recommendations listed below.

Safe operation of any gravity-vented gas-fired equipment requires a properly operating vent system, correct

provision for combustion air (See Paragraph 6), and regular maintenance and inspection. See Hazard Levels,

page 2.

Venting Requirements - Indoor Models

1.

Provide a minimum clearance of 18" (457mm) between the drafthood

relief opening and any obstruction. Do not expose the relief opening to

wind drafts from any source such as from an overhead door or adjacent

air handling equipment.

2.

The unit is equipped with a built-in draft diverter, consequently an

external draft diverter

MUST NOT

be installed in the vent connector or

**, *** See Notes under chart on the bottom of previous page.

Model Size

75

100

125 150, 175 200, 225 250, 300 350, 400

Flue Collar

Diameter/Configuration

5"

Round

6"

Round

7"

Oval

8"

Oval

8"

Round

10"

Oval

12"

Oval

Furnaces have

the following

vent outlet sizes:

any internal alterations made. Do not install a manual damper or

other fixed restriction in the vent connector.

3.

Vent pipe should be a minimum of 26-gauge galvanized steel or

other noncorrosive material. Double-wall, Type B vent is recom-

mended. Where it is necessary to run the vent pipe through an

exterior wall of combustible materials, a suitable thimble must be

used. The vent pipe shall have a clearance of at least six inches

(152mm) from combustible materials, or as is specified by the

double-wall vent pipe manufacturer.

4.

The horizontal vent pipe run should have a uniform rise of at

least 1/4" per foot (6.3mm per 305mm) of horizontal run in the

direction of discharge. The length of the lateral run must not

exceed lengths in the vent tables of the National Fuel Gas Code or

the Canadian Installation Code for Gas Burning Appliances. See

TABLES 1 and 2

on the right.

5.

Lateral runs should be supported every six feet (1.8M) using a

non-combustible material, such as strap steel or chain. Do not

rely on the drafthood or heater for support of either horizontal or

vertical vent pipe.

6.

Vent connectors serving Category I heaters (heater with non-

positive vent pressure and with a vent gas temperature at least

140°F above its dewpoint) shall not be connected into any por-

tion of a mechanical draft system operating under positive pres-

sure.

7.

Where it is necessary to use a long run of vent pipe, or where the

vent pipe is exposed to cold air, condensation within the pipe

may occur. There are two ways to overcome or eliminate this

problem.

(a)

Prevent condensation by insulating the pipe so that the tem-

perature of the flue products never drops below 250°F.

TABLE 1 - Maximum Horizontal Run for Double-Wall Type B

Connector and Double-Wall Type B Vent

Vent Diameter

ft

M

ft

M

ft

M

ft

M

ft

M

ft

M

6' (1.8M)

6

1.8

6

1.8

6

1.8

6

1.8

6

1.8

6

1.8

8' (2.4M)

8

2.4

8

2.4

16

4.9

16

4.9

16

4.9

16

4.9

10' (3.0M)

10 3.0 16

4.9

20

6.1

20

6.1

20

6.1

20

6.1

15' (4.6M)

16 4.9 16

4.9

30

9.1

30

9.1

30

9.1

30

9.1

20' (6.1M)

20 6.1 30

9.1

30

9.1

30

9.1

30

9.1

30

9.1

30' (9.1M)

20 6.1 40 12.2 40 12.2 40 12.2 40 12.2 40 12.2

10"

12"

Vertical

Height of

Vent

5"

6"

7"

8"

TABLE 2 - Maximum Horizontal Run for Single-Wall Metal Pipe

Vent Diameter

ft

M

ft

M

ft

M

ft

M

ft

M

ft

M

6' (1.8M)

2

0.6

2

0.6

2

0.6

2

0.6

2

0.6

2

0.6

8' (2.4M)

5

1.5

5

1.5

10

3.0

10

3.0

10

3.0

10

3.0

10' (3.0M)

5

1.5

10

3.0

15

4.6

15

4.6

15

4.6

15

4.6

15' (4.6M)

5

1.5

10

3.0

15

4.6

20

6.1

20

6.1

20

6.1

20' (6.1M)

N.R.

10

3.0

15

4.6

20

6.1

20

6.1

20

6.1

10"

12"

Vertical

Height of

Vent

5"

6"

7"

8"

S ize

75, 100,

125

150, 175

200, 225

250, 300

350

400

S ize

75, 100,

125

150, 175

200, 225

250, 300

350

400

A

1540

1540

1540

1540

1540

1540

A

2499

2638

2778

2988

3128

3267

B

618

757

897

1106

1246

1384

B

618

757

897

1106

1246

1384

C

**

1446

1446

1446

1446

1446

1446

C

**

2403

2543

2683

2893

3033

3173

D

**

522

662

802

1011

1151

1291

D

**

522

662

802

1011

1151

1291

A

2148

2148

2148

2148

2148

2148

A

3108

3248

3388

3598

3738

3877

B

618

757

897

1106

1246

1384

B

618

757

897

1106

1246

1384

C

**

2053

2053

2053

2053

2053

2053

C

**

3013

3153

3292

3503

3643

3759

D

**

522

662

802

1011

1151

1291

D

**

522

662

802

1011

1151

1291

Option CJ4 - Roof Curb for (H)CRGB and (H)RPB with Field-

Installed*** Cooling Coil Cabinet Option AU2 or AU3

Option CJ5 - Roof Curb for (H)CRGB and (H)RPB with Field-

Installed*** Cooling Cabinet and Downturn Plenum Option AU11,

AU12, AU13, or AU14

Option CJ2 - Roof Curb for (H)CRGB and (H)RPB with Factory-

Installed Downturn Plenum Option AQ5 or AQ8

Option CJ1 - Roof Curb for (H)CRGB and (H)RPB