Form I-XE/CRGB/RPB, Page 32

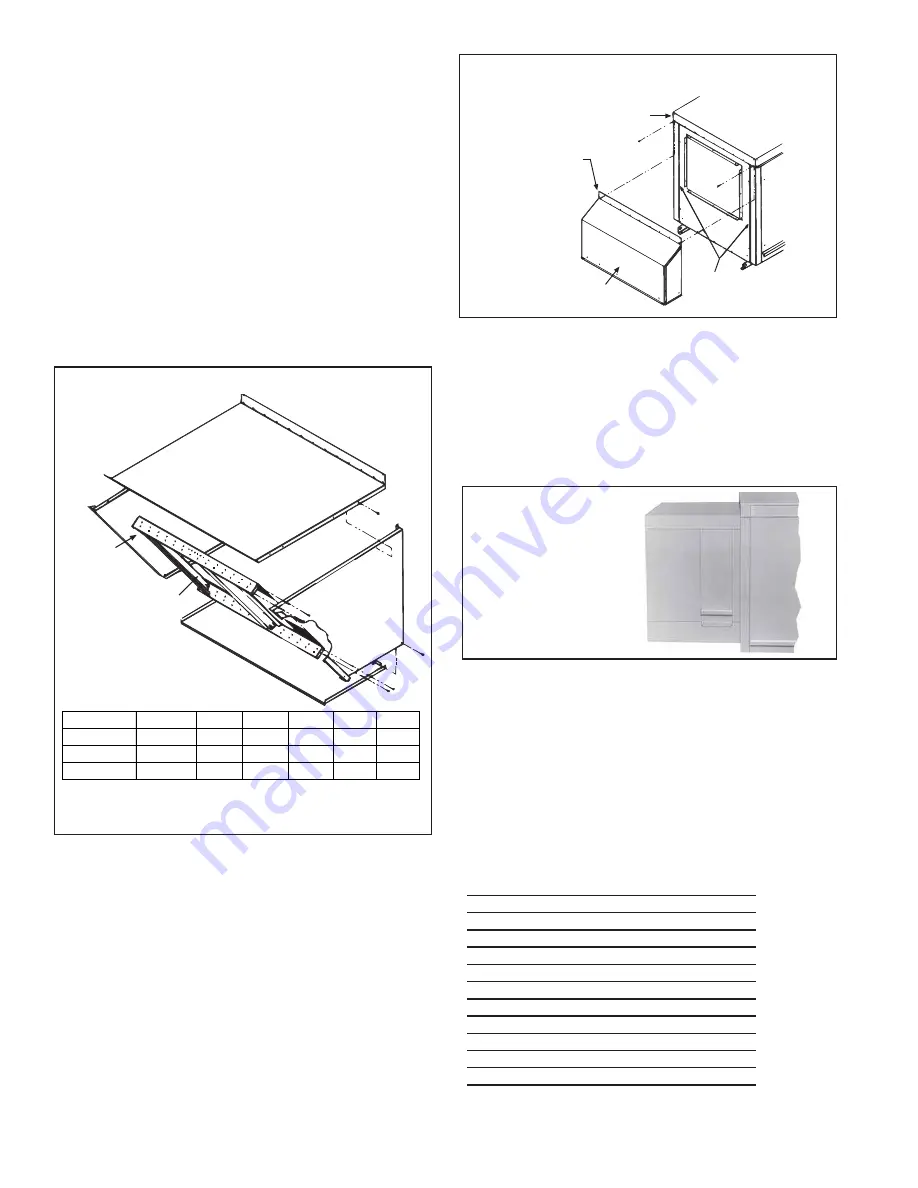

FIGURE 32 - Optional

Evaporative Cooling

Module is factory-

installed on the blower

cabinet

The optional evaporative cooling module is equipped with high effi-

ciency pad media of either 6" or 12" rigid cellulose (Option AS3 or AS4)

or 6" or 12" rigid glass fiber (Option AS5 or AS8). Six-inch media

provides 68% efficiency; 12" media provides 90% efficiency. Effi-

ciency values are stated at maximum allowable CFM without the addi-

tion of a moisture elimination pad with an inlet dry bulb temperature of

95°F and inlet wet bulb temperature of 65°F. The evaporative cooling

efficiency is a function of inlet temperature and of face velocity through

the media. The stated cooling efficiency will rise with the decrease of

CFM and the increase of inlet temperature. Moisture elimination pads

(Option ASA1) may be used on all units but are required on high CFM

units as listed below.

Heater

Moisture Elimination Pad Required

S i z e

on Evaporative Cooling Module

75

2601 - 2645 CFM

100

2601 - 3400 CFM

125

2601 - 3800 CFM

150

3201 - 4700 CFM

175

3201 - 5000 CFM

200

3701 - 5100 CFM

225

3701 - 5150 CFM

250

4501 - 5800 CFM

300

4501 - 6300 CFM

350

5101 - 6800 CFM

400

5601 - 7100 CFM

The standard water controls for the evaporative cooling module include

the float valve, the float switch, and pump assembly illustrated in the

following paragraphs. If the cooling module has an optional AquaSaver

TM

Top Panel (edge must be

underneath cabinet top)

Left Side

Panel

Right Side

Panel

Factory-assembled

Louver Assembly

including Moisture

Eliminating Louvers

(U.S. Patent 4,999,037)

and Screen

Bottom

Panel

NOTE:

Either a manufacturer designed optional air inlet hood as

shown in Paragraph 31 or an evaporative cooling module as shown

in Paragraph 33 is required to ensure complete weather resistance.

FIGURE 31 - Installation of Air Hood on Cabinets with

30% Outside Air Opening Options

Blower

Cabinet

Remove two corner and

compete row of screws

Slide top flange

underneath the

cabinet top

Vertical Slots -

Slide side flanges

into slots

30% Outside

Opening Air Hood

31. 100% Outside Air Hood (cont'd)

Hood Installation Instructions (cont'd)

FIGURE 30 - Assembly

Drawing of Option AS2

Outside Air Hood

3. Bottom Panel

- Position the air hood bottom panel so that it is to

the

inside

of the two side panels and

above

the factory-installed

support angle. Attach to the side panels.

If the bottom panel does not rest tightly against the support angle,

follow these instructions to adjust the position of the support angle:

a) Slightly loosen (do not remove the screws).

b) Slide the support angle up so that it is against the bottom

panel.

c) Tighten the screws.

Attach the support angle to the air hood bottom panel. The bottom

panel of the air hood and the support angle should be tight together;

do not draw with the sheetmetal screws.

4. Louver Assembly

- With the intake screen toward the inside of the

hood position the pre-assembled vertical louver assembly in the

inlet opening of the air hood. Using the remaining sheetmetal screws,

attach the louver assembly to the air hood side panels at the holes.

32. Screened Air Hood for 30%

Outside Air Opening, Part of Inlet

Air Options AR6 and AR7

(Outdoor models)

The outside air hood included in the air inlet options that have a 30%

outside air opening (Option AR6 or AR7) is shipped separately for field

installation. Instructions for attaching are packaged with the air hood.

Installation Instructions - 30% Outside Air Hood

1. On the inlet air side of the blower cabinet, remove the factory

installed screws attaching the blower cabinet top.

2. Slide the air hood top flange underneath the lip of the blower

cabinet top and the sides into the vertical slots.

The air hood

flange must be between the blower cabinet top and the

cabinet end panel.

3. Reinsert all of the sheetmetal screws.

33. Optional Evaporative Cooling

Module (outdoor models)

Evaporative cooling provides excellent comfort cooling at low initial

equipment and installation costs and low operating and maintenance

costs. Direct evaporative cooling works solely on the principle that

water in direct contact with a moving airstream will eventually evapo-

rate if the droplets have long enough exposure. This evaporative cool-

ing module uses wetted rigid cellulose or rigid glass fiber media to

retain water in order to allow time for evaporation.

Size

75,100,125 150,175 200,225 250,300

350

400

Top Panel

100227

100228 100229 100230 100231 100232

Bottom Panel

100234

100235 100236 100237 100238 100239

Louver Assy

103773

103774 103775 103776 103777 103778