Form I-XE/CRGB/RPB, Mfg No. 131782 Rev 4, Page 39

b) Position the assembled connectors so that the horizon-

tal screw holes will be in the

top

piece at the open side

(See FIGURE 46C)

. In this position, insert the

assembled top and bottom connectors

(FIGURE 46B)

into the space between the furnace and cooling coil

cabinet.

Tap with a hammer first on the side, then on the top,

and last on the bottom of the assembled duct connector

until it is seated over the duct flanges.

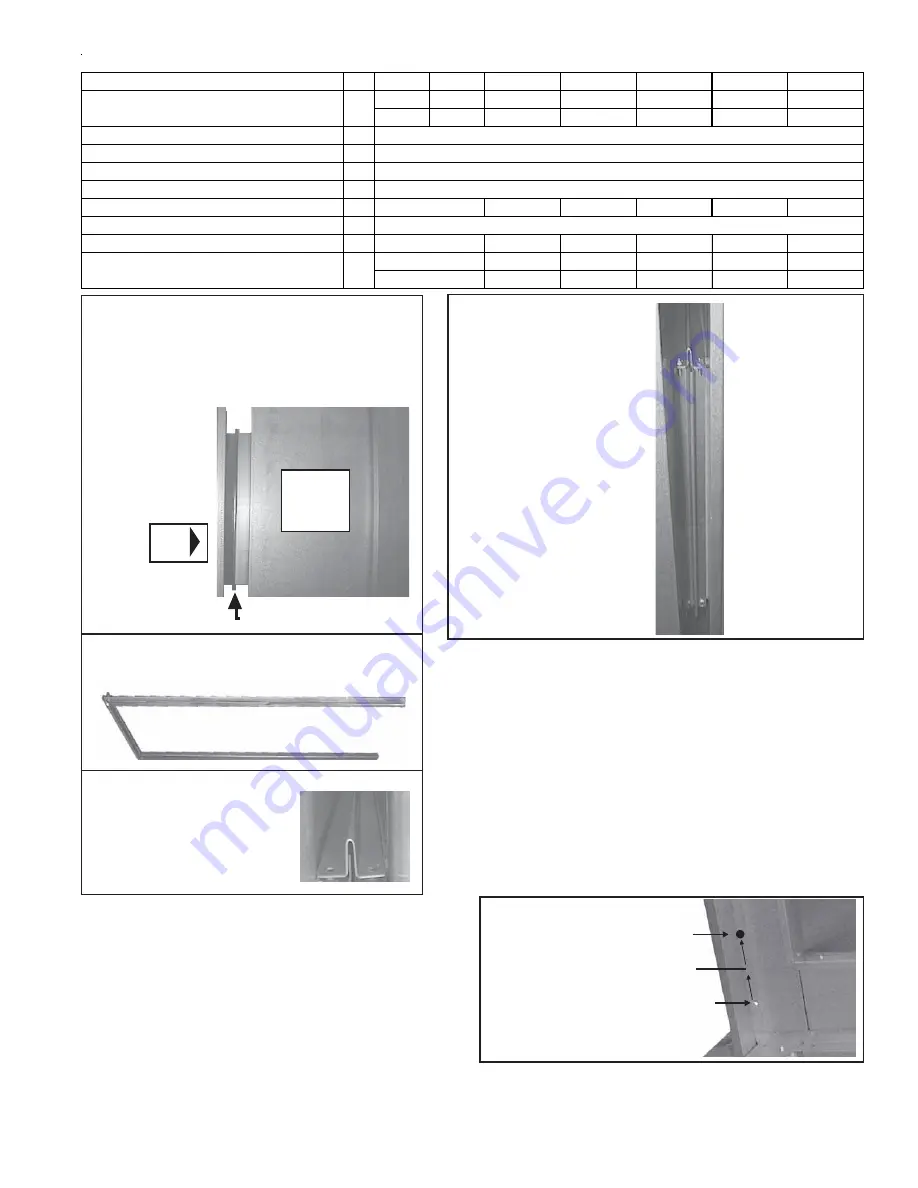

FIGURE 46A -

1) Place the cooling coil cabinet on the curb;

2) remove the lifting lugs; and

3) slide the cabinet so that the duct flange on the

cooling coil cabinet butts

against the duct

flange on the

furnace.

Furnace

Discharge

with Duct

Flange

Duct Flanges

A i r -

flow

Cooling

Coil

Cabinet

FIGURE 46B - Assemble top, bottom, and one side

of the duct connector pieces using the 3/4"

sheetmetal screws

FIGURE 46C - The end of

the top connector on the

"open side" of the

connector assembly.

c) Position the remaining side connector. Use the driver ex-

tension to insert the screws that attach the side connector

to the top and bottom connectors.

See FIGURE 46D.

FIGURE 46D - Position the

remaining side connector

over the duct flanges.

Attach to the top and

bottom connectors with 3/

4" screws creating a "U"

shaped rectangular frame

that joins the duct flanges

on all four sides.

Top

screws

should be

vertical.

5. Wiring Instructions - Apply to Downturn Plenum Cabinet with Op-

tional Discharge Dampers Only -

If installing an Option AU12 or AU14

cooling coil cabinet with a downturn plenum cabinet equipped with op-

tional discharge dampers, the damper motor wires must be connected to the

terminal blocks in the furnace electrical compartment. If the coil cabinet

being installed does not include a downturn plenum with a discharge damper,

skip Step 5 and proceed to Step 6.

a)

Drill three 7/8" holes as instructed below. Be sure all holes are free of burrs.

First Hole:

1) Remove the control side door on the discharge plenum.

2) Locate the discharge damper motor. Connected to the motor are three

wires in lengths adequate to reach the furnace section.

3) Refer to

FIGURE 46E

. On the leg of the downturn plenum next to the

cooling coil cabinet locate the mounting screw illustrated. Measure up

6" (152mm). At same centerline as the screw, drill the first 7/8" hole.

Factory-Supplied Parts for Attaching Cabinet to Furnace

Description

Qty 75, 100

125

150, 175

200, 225

250, 300

350

400

107426

107427

107428

107429

106338

106339

106340

14"

16-3/4"

21-1/4"

27-3/4"

36"

41-1/2"

47"

Side Duct Connectors Connectors

2

#14 x 3/4" long Sheetmetal Screws

8

Left Side Filler Panel

1

Right Side Filler Panel

1

Top Filler Panel

1

172360

172361

172362

172363

172364

Insulation, 1"x42"x9", for Side Filler Panels

2

#10 x 1/2" long Sheetmetal Screws

(_)

(21) 11813

(22) 11813

(24) 11813

(25) 11813

(26) 11813

Rubber Gasket Strip

103606

103607

103608

103609

103610

3/32" x 1-1/8" x

40-1/8"

45-5/8"

53-7/8"

59-3/8"

64-7/8"

Top/Bottom Duct Connectors

172546

172359

106305

34-5/8"

( 19) 11813

2

1

106395, 19-1/2" (495mm) long

105171

172357

172358

FIGURE 46E

3) Drill 7/8" Hole

2) Measure up

6" (152mm)

1) Locate

Mounting Screw

Second Hole:

1) Remove the cooling coil access panel(s).

2) Locate the coil blockoff plate. Measure up 4" (102mm) from the

bottom of the blockoff plate. At that location, find the centerpoint of