34

I-EEDU (02-21) 150492-A

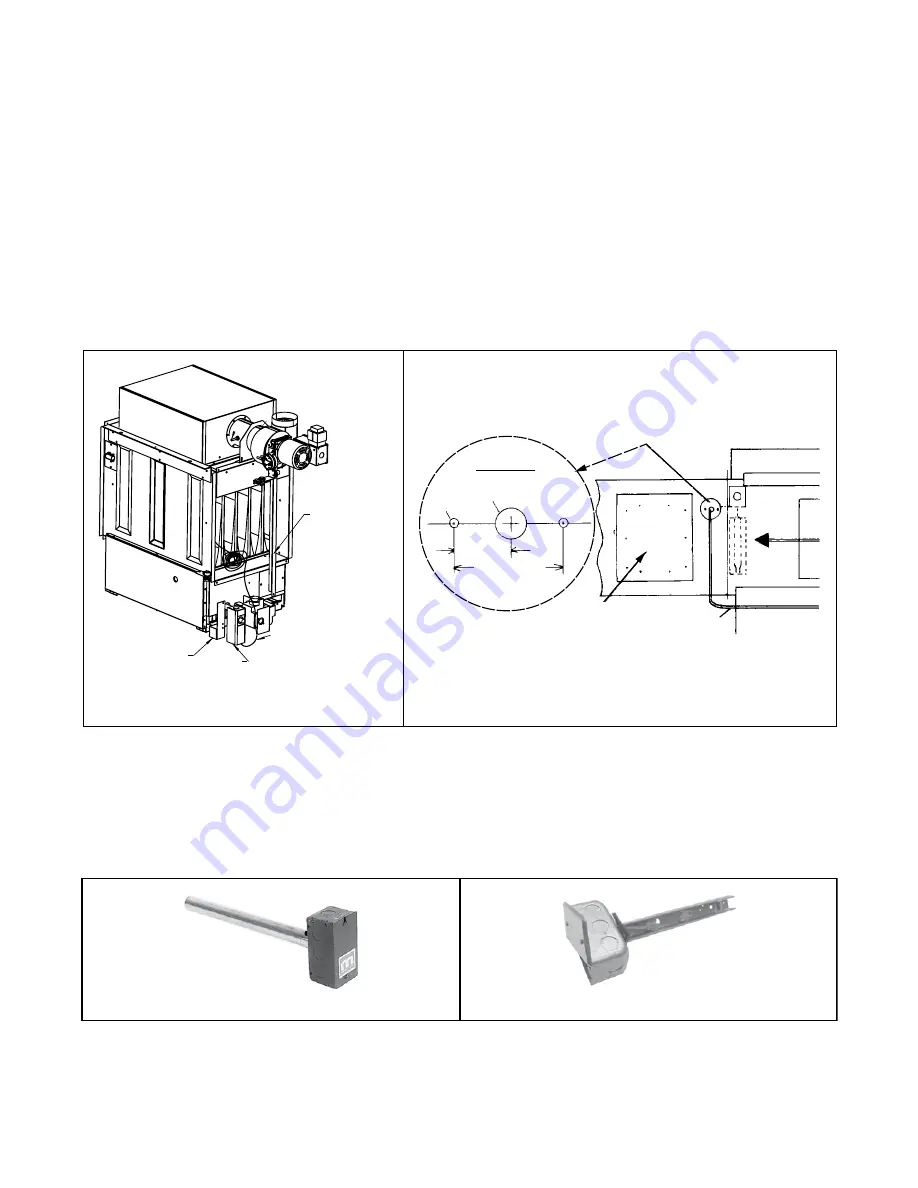

Figure 25. Installing Capillary Sensor Bulb in Discharge Ductwork (Option AG3)

Option AG8, AG9, or AG15: Discharge Air Temperature Sensor Installation

The discharge air sensors shown in

require field-installation in the discharge ductwork . Electronic modulation

options AG8 and AG9 include a sensor and mixing tube and makeup air option AG15 (two-stage valve with remote

ductstat) include a box and sensor holder (PN 115850) . Install the sensor in the ductwork as follows .

FIELD-INSTALLED OPTIONS—CONTINUED

Discharge Air Temperature Sensor Installation—Continued

Option AG3: Discharge Air Temperature Sensor Installation—Continued

4 . Select ductwork location so that minimum length of capillary tubing will be inside ductwork . Follow hole pattern

shown in

, DETAIL B to drill holes in ductwork .

5 . Remove ductwork access panel (see

6 . Remove sensor bulb from bracket and push sensor through 1/2-inch hole . While reaching through access hole,

use retaining clip to reinstall sensor to bracket .

7 . Slide gasket (cut slit) and hole retainer plate over capillary tubing . With gasket next to ductwork, install hole

retaining plate and secure using field-supplied sheet metal screws .

8 . Close ductwork access panel .

Shipping

Angle -

Remove

before

attaching

ductwork.

Ductstat Bracket

- Option AG3

Ductstat -

Option AG3

Ductstat Capillary with

sensing bulb attached

inside the furnace. To

connect ductwork, remove

the bulb with the bracket.

(Save bracket and clip.)

1/2” Diameter

1/8” Dia

3/4”

(19mm)

1-1/2” (38mm)

Capillary Tubing

to Ductstat

Airflow

Hole Pattern

Access

Panel

DETAIL A

DETAIL B

Figure 26. Discharge Air Temperature Sensor

DETAIL A: OPTIONS AG8 AND AG9

DETAIL B: OPTION AG15