15

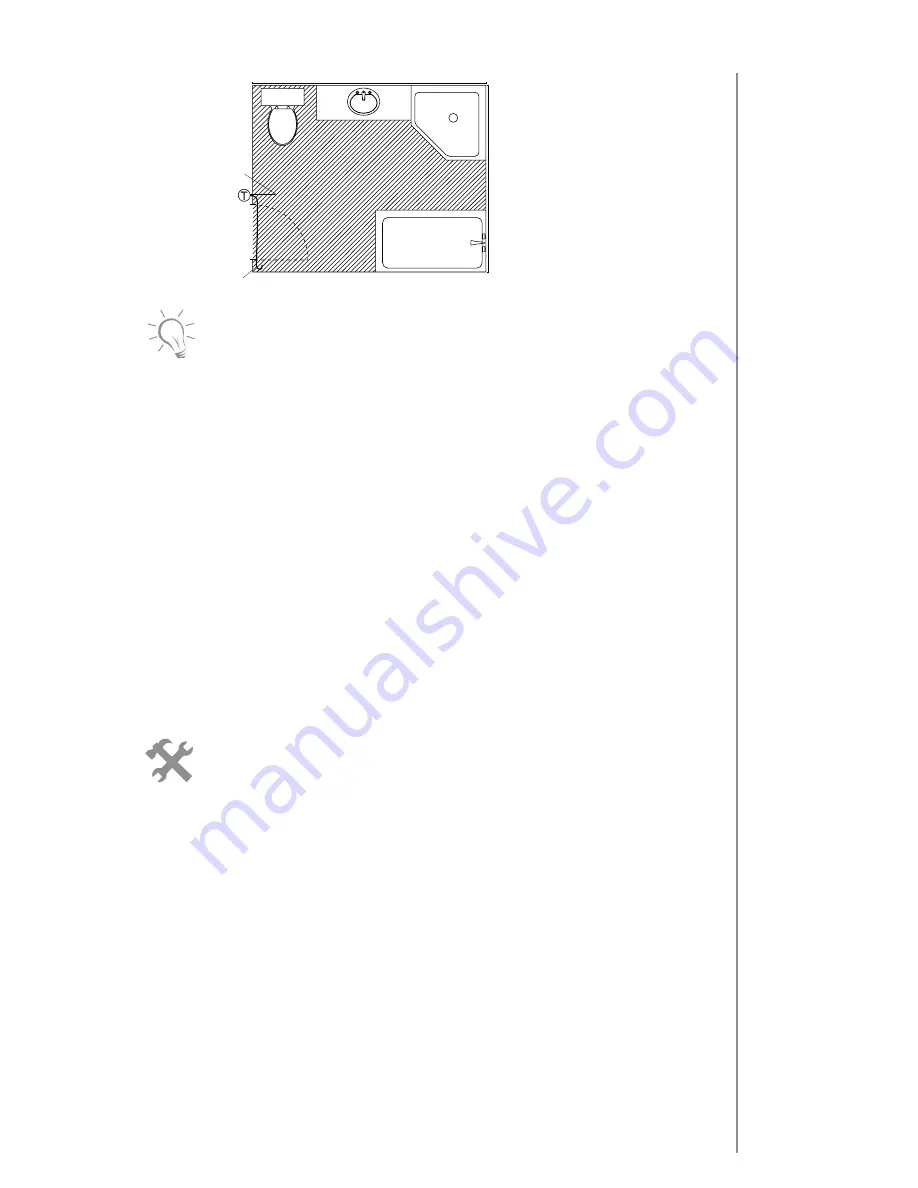

Fig. 4.1

cold lead

temperature

sensor

10'

8'

We can help optimize your work plan. Fax it to us at 724-662-3957. Clearly

indicate all dimensions. A minimum of one horizontal and one vertical

dimensions are necessary to validate the scale.

4.2 Preparing the Subfloor

• Clean and remove any debris, dust or protruding objects that could damage the

heating cable. The surface must be clean and dry for the adhesive mat to adhere

perfectly to the subfloor;

• Subfloor cracks must be filled with polyester wood filler;

• The subfloor must be solidly fastened in place to prevent movement;

• The application of a floor levelling product is recommended to prevent future

damage to the ceramic caused by subfloor movement;

• For concrete subfloors, apply a surface sealer that is compatible with electrical

heating systems in accordance with the cement glue manufacturer’s instructions.

Completely coat the surface;

• Let dry before installing the EFMA system (refer to the sealer’s instructions for

drying time).

4.3 Marking the Floor

Felt marker

• On the floor of an empty room (under construction or major renovations), draw the

location of stationary elements (toilet, bath, shower, counters, drawers, permanent

furnishings) that will be installed later. These marks will outline the heating area to

ensure the EFMA system is not placed under these stationary elements (Fig. 4.3 a);

• Draw lines on the floor the width of the mat 0.41 m (16”) or 0.82 m (32”);

• Indicate in which direction the EFMA system will be unrolled;