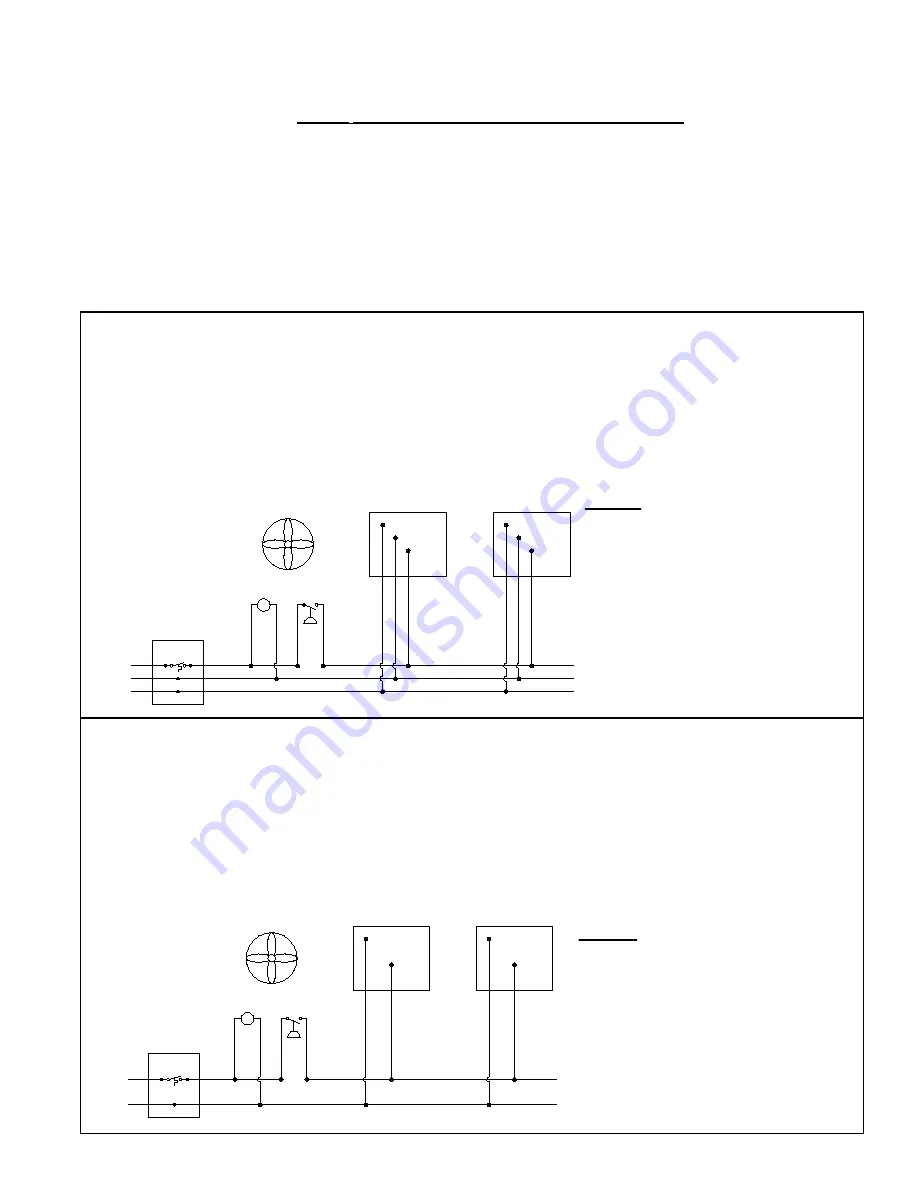

FIGURE 6A - With 120 VAC DIRECT SPARK IGNITION (DSI) SINGLE-STAGE CONTROLS

• Electrical supply: 120 VAC - 60 Hz - 1 Phase.

• Maximum total heater current draw: 0.14 Amps.

• Total heater power consumed: 16.8 VA (16.8W).

• 3-wire field service required.

• Field wiring having a minimum temperature rating of at least 302°F (150°C) shall be used and supply circuit

wiring shall have a minimum size of 16 AWG (1.0mm2).

FIGURE 6B - With 24 VAC DIRECT SPARK IGNITION (DSI) SINGLE-STAGE CONTROLS

• Electrical supply: 24 VAC - 60 Hz or 50 Hz - 1 Phase.

• Maximum total heater current draw: 0.66 Amps.

• Total heater power consumed: 15.9 VA (15.9W).

• 2-wire field service required.

• Field wiring having a minimum temperature rating of at least 302°F (150°C) shall be used and supply circuit

wiring shall have a minimum size of 16 AWG (1.0mm2).

GND

(-)

(+120)

GGS

BK

BK

GGS

VR*

SW*

MV*

W

W

120 VAC DSI HEATER ELECTRICAL SUPPLY AND THERMOSTAT WIRING*

LEGEND

(+120) = 120 VAC Supply Voltage

(-

(-) = Supply Neutral

GND = Earth Ground

MV* = Mechanical Ventilation*

VR* = Ventilation Relay*

SW* = Ventilation Interlock Switch*

(normally opened)

GGS = Green Ground Screw

(inside control box)

W = White Wire – Neutral

BK = Black Wire – 120 VAC call for heat

Thermostat

Heater 1

Heater 2

GND

(+24)

GGS

BL

BL

GGS

VR*

SW*

MV*

24 VAC DSI SINGLE-STAGE HEATER ELECTRICAL SUPPLY AND THERMOSTAT WIRING*

LEGEND

(+24) = 24 VAC Supply Voltage

GND = Earth Ground

MV* = Mechanical Ventilation*

VR* = Ventilation Relay*

SW* = Ventilation Interlock Switch*

(normally opened)

GGS = Green Ground Screw

(inside control box)

BL = Blue Wire – 24 VAC call for heat

Thermostat

Heater 1

Heater 2

7.2 Electrical

Requirements

by Voltage and

Control Types

More specific electrical requirements may vary depending on whether the unit is sin-

gle-stage (115V), single-stage (24V), or two-stage (24V). Select the information that

applies to the unit being installed.

NOTES

common to FIGURES 6A, 6B, and 6C (page 12):

•

* Mechanical ventilation interlock is required when all combustion air is provided

by a mechanical air supply system.

•

#10 ring terminal is required for ground service conductor (by others) to attach to

green ground screw on heater.

•

The heater control is extremely polarity sensitive and the heater will cycle on

and off erratically if the electrical supply is not wired correctly. Have a qualified

electrician check that the electrical supply circuit is properly grounded and that the

electrical supply polarity is correct.

•

All components and wiring illustrated are field-supplied.

Form I-RIH, P/N 131793R8, Page 11