26

SSCBL-RPBL-IOM (10-22) 149159-C

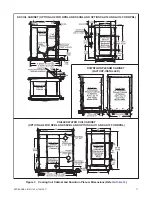

DETAIL A: SENSOR AND MIXING TUBE

DETAIL B: SENSOR HOLDER

INSTALLATION—CONTINUED

Duct Connections—Continued

Discharge Air Temperature Sensor Installation—Continued

3 . Secure sensor in ductwork:

a . Position of sensor in duct is also important—mixing tube shown in

, DETAIL A is 12 inches (305 mm)

long and holder shown in

, DETAIL B extends 9-3/16 inches (233 mm) into ductwork .

b . For units with sensor holder, turn holder so that element is shielded from direct airflow and will sense air

temperature as it flows through holes in holder .

c . At selected ductwork location, mark diamond-shaped hole—approximately 1

×

1 inch (25

×

25 mm—required

for sensor holder or round hole required for mixing tube and cut hole no larger than necessary .

d . For units with sensor and mixing tube, slide mixing tube (see

, DETAIL A) into ductwork and attach

sensor .

e . For units with sensor holder, push element into clip in holder (see

, DETAIL B), slide holder into

ductwork, and position holder so that it shields sensor from direct airflow . Secure box portion of holder to

ductwork using four field-supplied #6 sheet metal screws .

Figure 17. Discharge Air Temperature Sensor and Holder

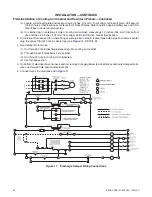

f . For units with option AG39 or AG41:

(1) Sensor is factory-installed in cabinet leg (see

) . Remove access panel in ductwork adjacent to

control compartment access panel .

(2) Element is retained by either spring clips or cable straps .

(3) Round gasket and metal retaining plate provide airtight seal for capillary and must be removed to remove

element .

Figure 18. Discharge Air Temperature Sensor Location (Options AG39 and AG41)