51

SSCBL-RPBL-IOM (10-22) 149159-C

Optional Two-Stage Control (Makeup Air Application)

•

On systems with more than one furnace section, there are two methods of achieving multiple-stage makeup air

operation . In addition, for each of these methods, there are two types of control mechanisms . Consult the wiring

diagram on the furnace to identify the optional control system: option AG3, AG4, AG5, AG15, AG17, or AG19 .

• Option AG3 or AG15:

The first method is comparable to the two-stage heating units . Instead of control from a

two-stage room thermostat, the discharge air temperature is monitored and the two-stage gas valve is controlled

by a two-stage ductstat . When the discharge air temperature drops to the setpoint, low fire is energized . If low

fire cannot satisfy the ductstat setting, high fire is energized . As the packaged system may include two or three

furnace sections, and as each section is equipped with a two-stage gas valve, the operation stages increase with

the number of furnace sections . Set the ductstat as indicated in

.

• Option AG4, AG5, AG17, or AG19:

The second method of multiple-stage makeup air operation is applicable only

to systems that include two or three furnace sections . On systems with two furnaces, this optional control system is

identified as option AG4 or AG17 . On packaged systems with three furnace sections, this optional control method

is identified as option AG5 or AG19 . Each furnace in the package is equipped with a single-stage gas valve . The

single-stage gas valves are staged by two-stage ductstats . The furnaces are staged in sequence . This concept

will achieve two-stage control on packaged systems with two furnaces and three-stage control on systems with

three furnaces . Set the ductstat as indicated in

.

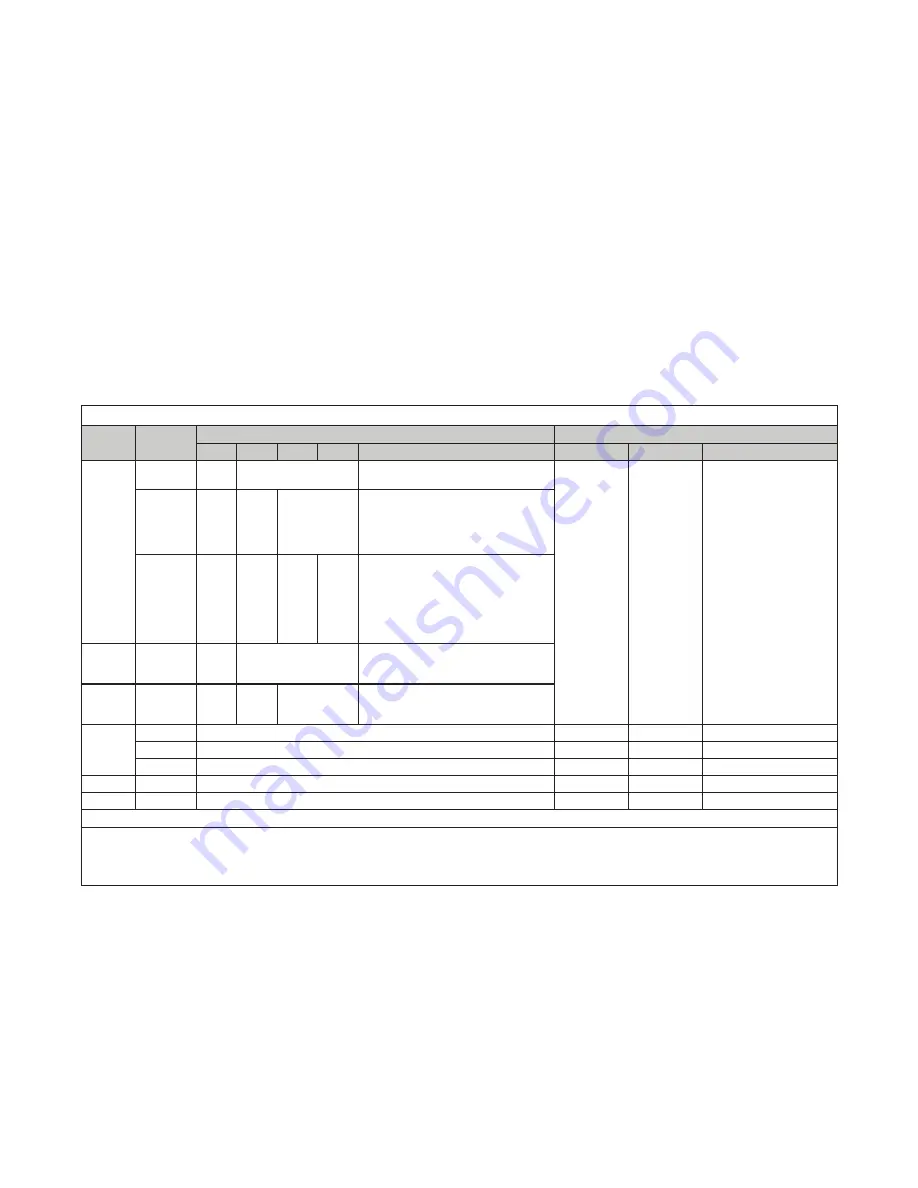

Table 27. Recommended Settings for Two-Stage Makeup Air Control

Option

No. of

Furnaces

Ductstat Setting

*

Temperature Selector Setting

**

1st

2nd

3rd

4th

Staging Sequence

Setpoint

Differential

Stage Adder Offset

AG3

1

70°F

—

66°F high stage

→

70°F low stage

→

74°F shutdown

—

—

—

2

70°F

64°F

—

60°F high stage (both furnaces)

→

64°F low stage (furnace 2)

→

68°F shutdown (furnace 2)

→

70°F low stage (furnace 1)

→

74°F shutdown (furnace 1)

3

70°F

66°F

62°F

—

58°F high stage (all furnaces)

→

62°F low stage (furnace 3)

→

66°F shutdown (furnace 3),

low stage (furnace 2)

→

70°F shutdown (furnace 2),

low stage (furnace 1)

→

74°F shutdown (furnace 1)

AG4

2

70°F

—

66°F full rate (both furnaces)

→

70°F shutdown (furnace 1)

→

74°F shutdown (furnace 2)

AG5

3

70°F

64°F

—

60°F full rate (both furnaces)

→

68°F shutdown (furnace 3 and 2)

→

74°F shutdown (furnace 1)

AG15

1

—

74°F

8°F

4°F

2

—

74°F

14°F

10°F, 6°F, 4°F

3

—

74°F

16°F

10°F, 8°F, 8°F, 4°F, 4°F

AG17

2

—

74°F

8°F

4°F

AG19

3

—

74°F

10°F

6°F, 6°F

*

Set each ductstat control in furnace order .

**

Adjust the setpoint and the differential of the temperature selector (Johnson #A350) . Adjust the offset potentiometer on each of the stage

adder modules (Johnson #S350) . Follow the manufacturer’s instructions provided .

IMPORTANT:

Set the temperature selector and each

stage adder module to HEAT . Follow the wiring diagram to obtain proper sequencing .

Operation:

The differential setting and offset degrees

allow the controls to adapt to any adjustment in temperature selection (50–130°F) .

Optional Ductstat with Capillary Tubing (Option AG3, AG4, or AG5)

The makeup air control options with the complete two-stage ductstat installed in the heater discharge use a ductstat

(see

, DETAIL A) with an adjustable range between 0° and 100°F with a fixed differential of 2-1/2° . Due

to different CFM settings and outside air temperatures, the average downstream outlet temperature may not match

the ductstat setting exactly . After the installation is complete, re-adjust the setpoint of the ductstat(s) to achieve the

desired average discharge air temperature . In general, makeup air applications are usually adjusted to discharge

an outlet air temperature between 65°F and 75°F .