52

SSCBL-RPBL-IOM (10-22) 149159-C

CONTROLS—CONTINUED

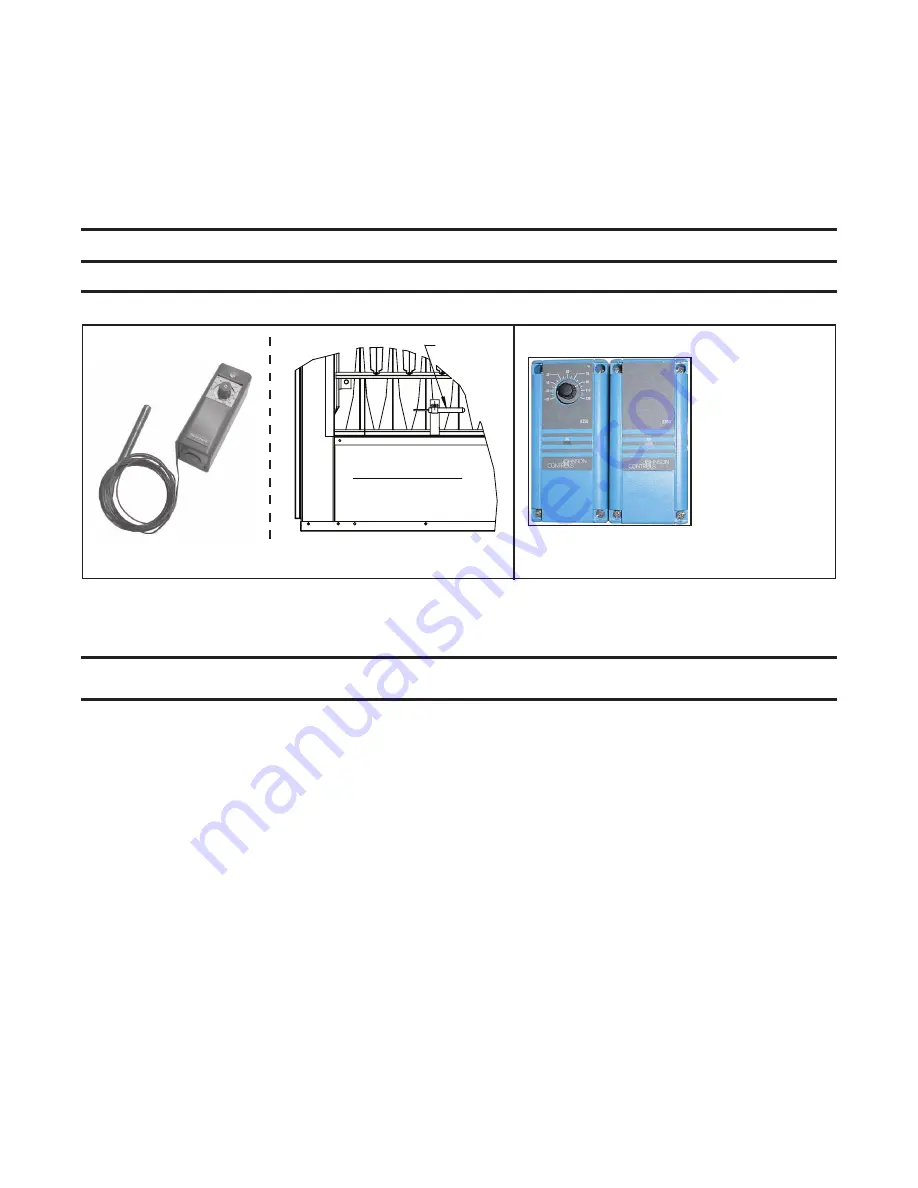

Optional Ductstat with Remote Temperature Selector (Option AG15 , AG17, or AG19)

Two-stage makeup air options that are controlled from a sensing probe with a remote electronic temperature selector

have a temperature operating range to 130°F . The sensing probe and remote modules (see

shipped separately for field installation . Follow the wiring diagram with the unit and the manufacturer’s instructions for

wiring and installing the remote modules . Depending on the staging provided, there will be one module for selecting

temperature and one to five stage-adder modules . The digital display module is optional .

⚠ CAUTION ⚠

Ensure that the heat/cool selector switch on the remote temperature selector is positioned to

Heat

.

Ductstat Bulb

Typical Duct Furnace

Front (Discharge) View

DETAIL A: OPTIONS AG3, AG4, AND AG5

(A) Remote

Temperature Selector

(B) Stage-Adder

Module

(A)

(B)

DETAIL B: OPTIONS AG15, AG17, AND AG19

Figure 37. Ductstat Options

Optional Electronic Modulation

NOTE: Unit sizes 400, 700, 800, 1050, and 1200 with electronic modulation require a minimum

natural gas supply pressure of 6 IN WC.

The type and capability of the electronic modulation system depends on the option selected . Electronic modulation

options are identified by a suffix to the serial No . printed on the heater rating plate . AG7 is identified as MV-1, AG8

is identified as MV-3, AG9 is identified as MV-4, AG21 is identified as MV-A, AG39 is identified as MP-1, and AG40

is identified as MP-2 . AG39 and AG40 are available only on unit size 400 . AG41 is identified as MP3 and AG42 is

identified as MP4 . Both AG41 and AG42 apply only to unit sizes 500, 600, 800, and 1200 .

Electronic Modulation Between 50% and 100% Firing Rate (Option AG7, AG8, or AG9)

•

Depending on the heat requirements established by the thermistor sensor, the burner modulates between 100%

and 50% firing . The thermistor is a resistor that is temperature-sensitive in that as the surrounding temperature

changes, the Ohms resistance changes through the thermistor . This change is monitored by the solid-state control

center (amplifier) that furnishes varying DC current to the modulating valve to adjust the gas input .

•

Each modulating valve is basically a regulator with the electrical means of raising and lowering the discharge

pressure . When no DC current is fed to this device, it functions as a gas pressure regulator to supply 3 .5 IN WC

pressure to the combination gas valve .

•

Refer to the wiring diagram provided with the furnace for proper wiring connections .

•

Electronic modulation for heating that is controlled by a specially-designed room thermostat (60–85°F) is identified

as option AG7 .

•

Electronic modulation for makeup air application that is controlled by a duct sensor and temperature selector

(55–90°F) is identified as option AG8 or AG9 . The temperature selector setting for option AG8 is on the amplifier

(see

) . Option AG9 has a remote temperature selector . Both systems are available with an override

thermostat .