63

SSCBL-RPBL-IOM (10-22) 149159-C

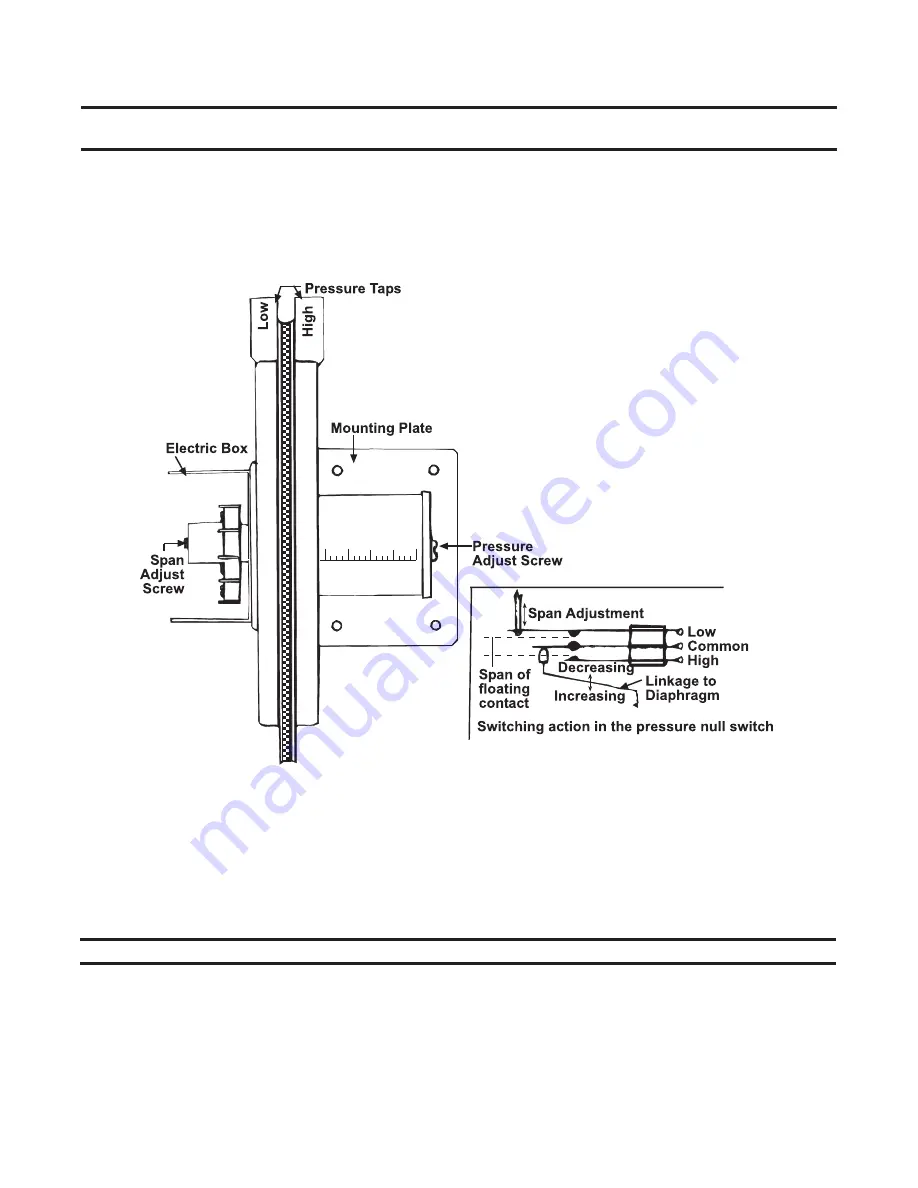

Figure 45. Pressure Null Switch Adjustment

Measure and Adjust Manifold (Outlet) Gas Pressure

Measuring manifold gas pressure cannot be done until the heater is in operation (refer to

section) .

• For natural gas:

When the heater leaves the factory, the combination valve is set so that the outlet gas pressure

of a single-stage valve or high fire of a two-stage valve is regulated to 3 .5 IN WC . Low fire on a two-stage valve

is set to 1 .8 IN WC . Inlet supply pressure to the valve must be a minimum of 5 IN WC or as noted on the rating

plate and a maximum of 14 IN WC .

NOTE: Always check the rating plate for minimum gas supply pressure.

• Minimum natural gas supply pressure:

Requirements vary based on size of burner and the gas control option .

Most units require a minimum of 5 IN WC natural gas as stated above, but sizes 400, 700, 800, 1050, and 1200

with electronic modulation require a minimum of 6 IN WC natural gas supply pressure .

• For propane gas:

When the heater leaves the factory, the combination valve is set so that the outlet gas pressure

of a single-stage valve or high fire of a two-stage valve is 10 IN WC . Low fire on a two-stage valve is set to 5 IN

WC . Inlet pressure to the valve must be a minimum of 11 IN WC and a maximum of 14 IN WC .

Pressure Null Switch Adjustment

NOTE: IMPORTANT: To eliminate shipping damage to the pressure null switch contacts, the manu-

facturer reduced the span adjustment to zero before shipping.

The span should be adjusted prior to using the pressure null switch (see

) as follows:

1 . If switch has been installed, disconnect vent tube so that switch is in neutral position .

2 . Remove electrical box cover and, while observing contacts, turn span adjustment screw slowly in clockwise direction .

3 . Continue turning adjustment screw until you are able to see gaps between common and both low and high

contacts—minimum gap provides greatest sensitivity—wider gap provides lower sensitivity .