70

SSCBL-RPBL-IOM (10-22) 149159-C

MAINTENANCE—CONTINUED

Maintenance Procedures—Continued

Cleaning Pilot and Burners

⚠ WARNING ⚠

To prevent injury when cleaning pilot and burners, wearing eye protection is recommended.

⚠ CAUTION ⚠

To prevent damage to pilot orifice, do not ream the orifice.

If the pilot flame appears short and/or yellow, check the pilot orifice for blockage caused by lint or dust accumulation .

1 . Remove the pilot orifice and clean it using compressed air .

2 . Check and clean the aeration slot in the pilot burner .

3 . Clean the metal sensing probe and the pilot hood with an emery cloth and wipe off the ceramic insulator .

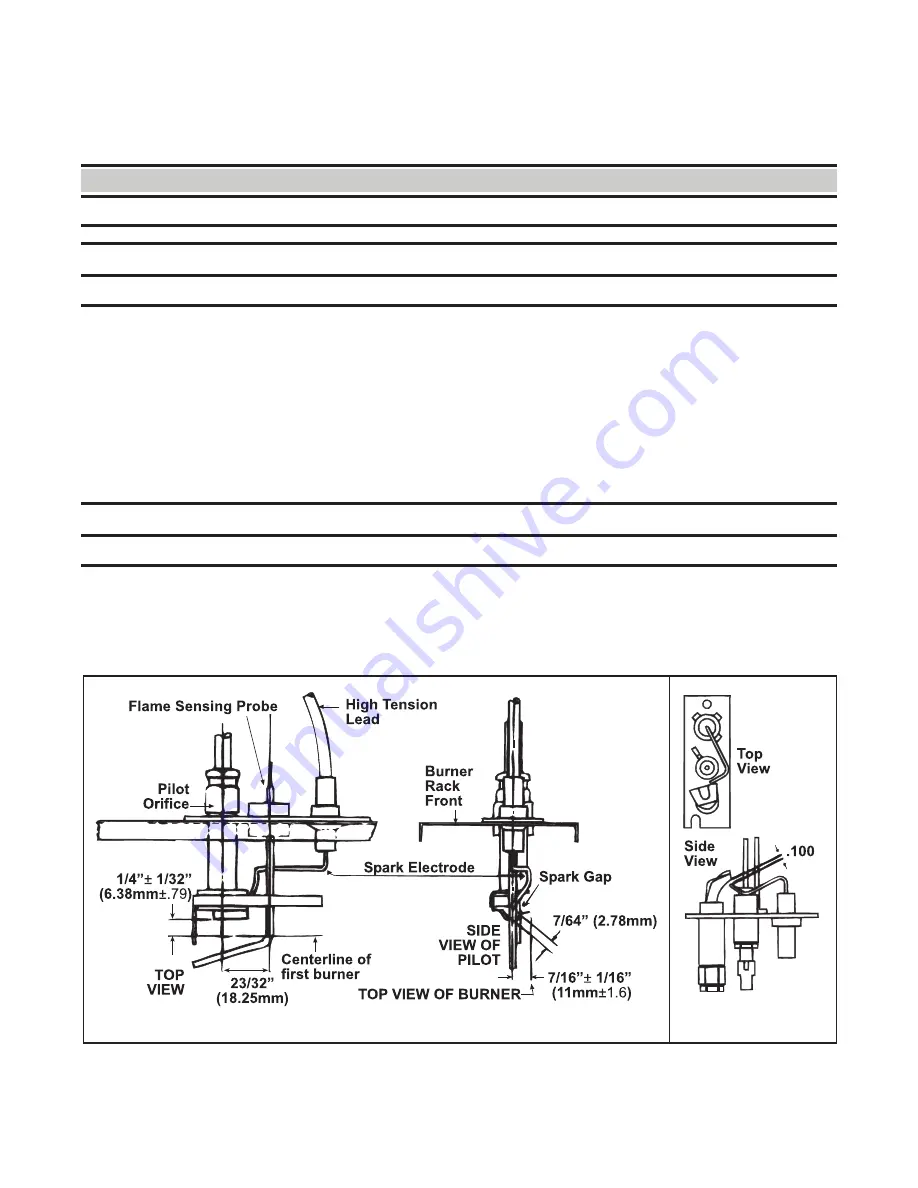

4 . Check the spark gap (see

), which should be maintained to 7/64 inch for RPBL models or 0 .100 inch

for SSCBL models .

5 . After the pilot is cleaned, blow away any dirt using compressed air .

6 . Clean the main burners and burner orifices using compressed air .

⚠ CAUTION ⚠

When cleaning burner ports, do not use anything that might change the port size.

7 . Use an air nozzle to blow out scale and dust accumulation from the burner ports . Alternate blowing compressed

air through the burner ports and then through the venturi . Use a fine wire to dislodge any stubborn particles from

the burner ports .

8 . Clean the burner rack carryover systems using compressed air .

Figure 50. Pilot Assembly Spark Gap

MODEL RPBL

MODEL SSCBL