4

DTR_314-05-01-001_EN_a

3.2

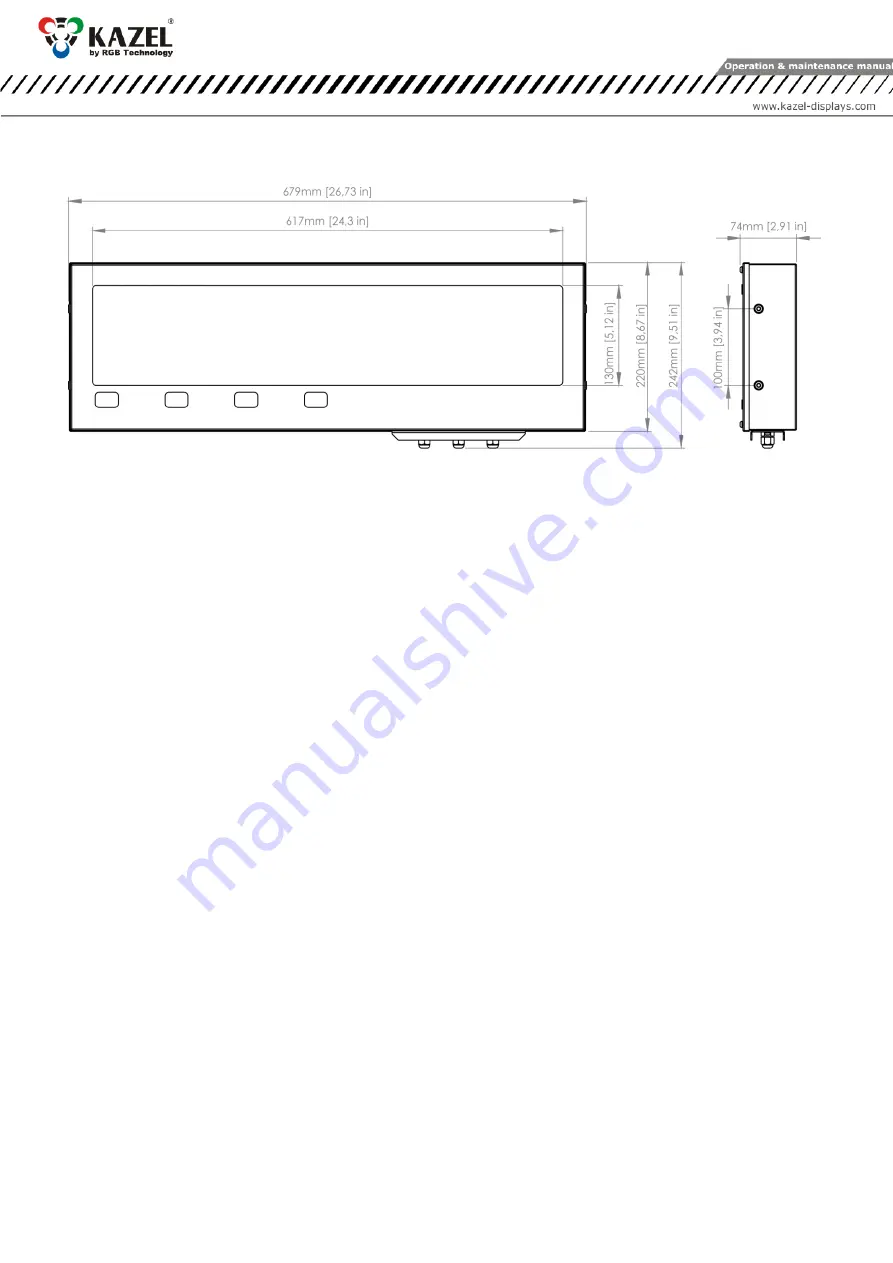

RM-470 dimensions

3.2.1

Dimensions without accessories

Fig. 2

4.

Device installation

The device should be mounted on a flat surface, with the wires facing down. Only the correct installation of the

device ensures its proper operation and the maintenance of the device parameters, such as housing tightness to

the declared IP class.

NOTICE!

Before any installation or maintenance operations, refer to the manual supplied by the manufacturer. Improper

connection to the mains power supply, incautious device installation, or improper use may cause property

damage, loss of health or death from an electric shock! In addition, failure to comply with the manufacturer's

instructions may void the warranty.

NOTICE!

It is forbidden to make any additional mounting points or any holes in the device components.

4.1

RM-470 application

RM-470 is designed to display measurement results transmitted by weighing terminals. The displays operate in

the automatic mode by default (see 4.2 "Autolearn”) and, in typical cases, they do not require prior

configuration. In special situations, it may be necessary to adjust the settings using RGB WagSet 2 software or

the Web-panel or through the user menu embedded in the device.

4.2

"Autolearn” function

The “Autolearn” mode is enabled by default (position #0 is set in the "proto" submenu). To disable it, the

communication protocol should be selected manually using the embedded user menu or RGB WagSet 2

software or the Web-panel. When this mode is active, at each start-up, the device detects the parameters of

communication with the weighing terminal and analyses the structure of the data frames which are sent to it. It

then adjusts its settings to allow proper communication with the terminal. The whole operation lasts a few

seconds, depending on the baud rate and time intervals between the consecutive frames. All communication

interfaces are supported, i.e. RS-232, RS-485/RS-422, 0/20mA digital current loop and the Ethernet.

The "Autolearn" procedure steps and their signalling are as follows:

1. Baud rate detection - dot 1 is flashing on the display,

2. Baud rate verification - dot 1 is solid, dot 2 is flashing,

3. Analysis of the protocol and its frame structure - dots 1 and 2 are solid, dot 3 is flashing.

During the analysis of the protocol and its frame structure, the measurement unit is also recognised, if sent by

indicator. The following tags are recognised - "kg" 'k' 'K' "tn" "TN" " t" 'T' 't' "LB" "lb" 'L' 'l' "OZ" "oz" 'o' 'O'. In

case the indicator does not send units or sends units that are not recognised by the “Autolearn” function, the

default unit will be set. Depending on the purchased regional version, it is "kg" or "lb".