DTR_319-01-01-001_EN_b

5

4.1

Alternative mounting options

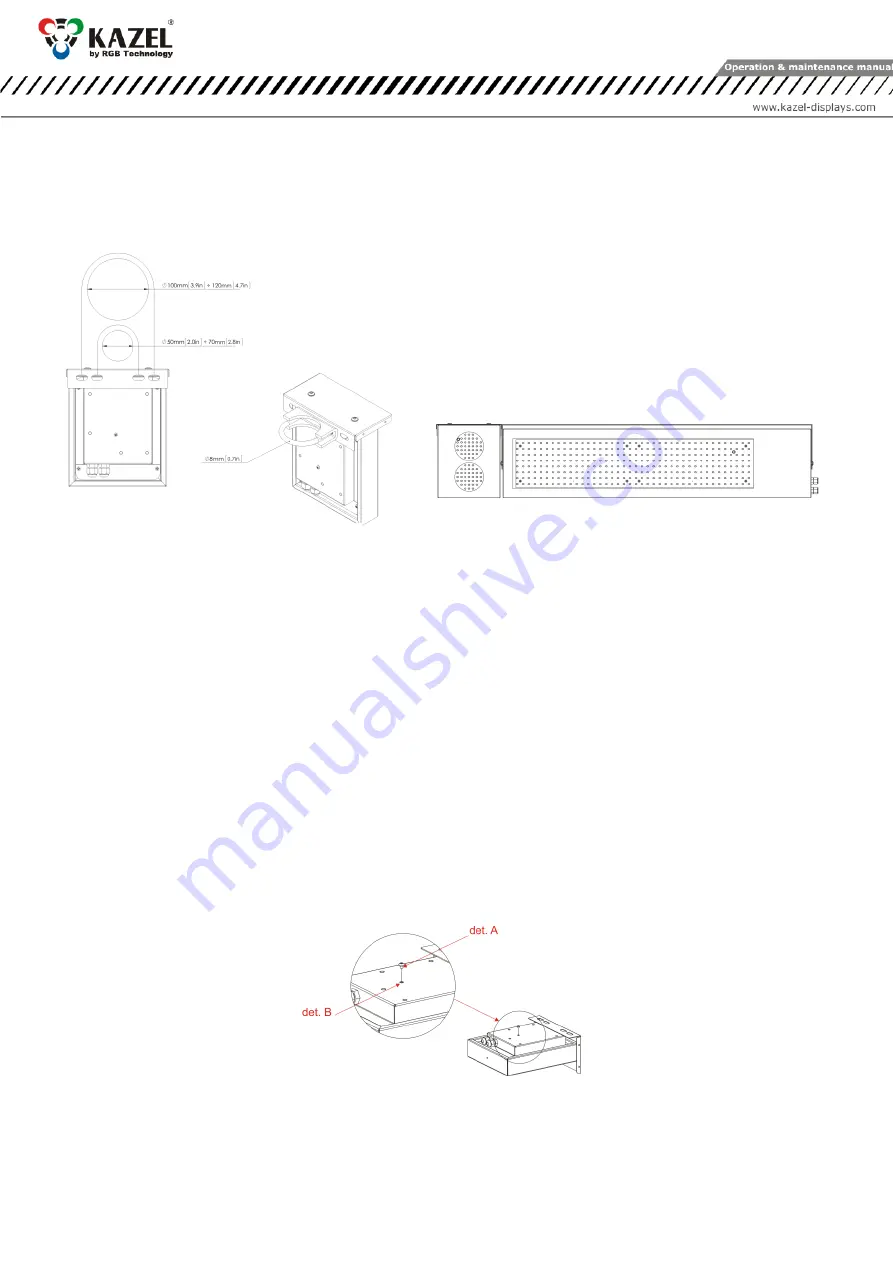

The roof construction allows you to mount the signalling device on posts with diameters of 50÷70mm [2÷2.8in]

and 100÷120mm [3.9÷4.7in], using a U-bolt with a rod diameter of 8mm [0.7in] (Fig. 4), or on the WA-2

Professional weighing scale display housing, using the mounting holes on the roof side (Fig. 5).

4.2

TL-70-2 application

The device is designed for traffic control. It allows you to signal the driving possibility or the traffic ban and to

determine the driving direction. The signalling device can also be used to present the industrial machinery

status. For the proper operation of the device, it necessary to pre-configure it using the embedded user menu.

4.3

TL-70-2 configuration

The configuration of the device using the menu allows:

1

Choice of a communication protocol with a control module, such as a weighing terminal, an operator

panel

2

Determining the response to the events reported by the control module

4.3.1

Defining communication protocols

4.3.1.1

Embedded user menu ("DEF" microbutton)

The user menu embedded in the device allows you to select a communication protocol, display the information

about the software version, display the set protocol, reset to the default settings. The DEF microbutton, used to

operate the menu, is located inside the signalling device. However, after unscrewing the lock screw it is

accessible through the technological hole without opening the device.

det. A

- lock screw;

det. B

- technological hole

Fig. 6

The user menu is called up by pressing and holding down the "DEF" microbutton and releasing it when the

desired option is displayed. Regardless the option, you can exit the user menu by pressing the microbutton and

releasing it when switching between the options (while switching between the options, the display is not

displaying any information).

Fig. 4

Fig. 5