11

6

INSPECTION AND MAINTENANCE

6.1

GENERAL MAINTENANCE RULES

1.

Proper maintenance of the Handihoist and related equipment consists of adhering to all the guidelines given in this

chapter and in the Pre-Hoisting Checklist in the front of this manual. Proper maintenance is required to maintain the

system in good condition, which is defined as each part being free of rust or other corrosion, bends, breaks, or other

defects.

2.

Review and follow all the safety rules given in Chapter 1 before attempting any maintenance.

3.

Only authorized personnel should be allowed in the maintenance area. Authorized personnel are the trained people as

defined below and their supervision.

4.

Repairs must be made only by trained personnel. A trained person is one who has read and thoroughly understands

this instruction manual and related equipment manuals and, through training and experience, has shown knowledge

regarding the safe operational procedures.

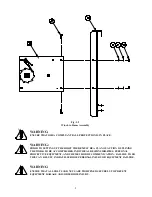

WARNING:

WEAR HEAVY LEATHER GLOVES WHEN HANDLING WIRE ROPE. INSUFFICIENT HAND

PROTECTION WHEN HANDLING WIRE ROPE CAN CAUSE SERIOUS PERSONAL INJURY.

5.

Do not weld or otherwise modify the hoist. Such alterations may weaken the structural integrity of the hoist and

invalidate your warranty.

WARNING:

DURING ANY ERECTION, MAINTENANCE, OR REPAIR PROCEDURES, DO NOT ATTEMPT

ANY HOISTING. THIS CAN CAUSE EQUIPMENT DAMAGE AND/OR SERIOUS PERSONAL

INJURY.

WARNING:

NEVER CLIMB THE TRACK TO DO MAINTENANCE. THIS CAN LEAD TO SERIOUS

PERSONAL INJURY.

6.2 INITIAL INSPECTION

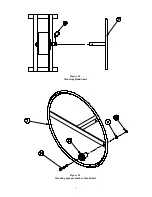

Hoist erection and dismantling must be done by trained personnel only as defined in Section 6.1. Each time after setting

up the hoist and before placing it in service, all parts of the Handihoist, and other related equipment must be thoroughly

inspected by trained personnel as described in the remainder of this chapter.

6.3

DAILY INSPECTION

It is important that all the maintenance procedures outlined in the Pre-Hoisting Checklist in the front of this manual be

done daily. Details on inspecting the wire rope are given in Section 6.7.

All broken, worn or defective parts must be repaired or replaced before startup.

6.4

OILING MECHANICAL PARTS

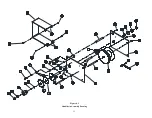

1.

Oil all pivots, bushings and linkage joints occasionally.