47

LP

Co

nv

ers

ion

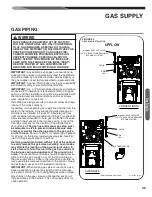

GAS VALVE

This furnace has a 24-volt gas valve. It has ports for

measuring supply and manifold gas pressure. The valve

body contains a pressure regulator to maintain proper

manifold gas pressure.

A control switch is on the valve body. It can be set to only

the

“ON”

or

“OFF”

positions. The gas valve is a slow-

opening valve. See Figure 32.

When energized, it takes 2 to 3 seconds to fully open.

1.

LP TANKS FROM LOCAL LP SUPPLIER MUST NOT

BE USED TO STORE ANYTHING (SUCH AS FER-

TILIZER) EXCEPT LP GAS. THIS INCLUDES ALL

DELIVERY VESSELS (LP TRUCKS). IF MATERIAL

OTHER THAN LP GAS IS USED IN THE SAME VES-

SELS/TANK AS THE LP GAS, THE LP GAS CAN

BECOME CONTAMINATED AND DAMAGE THE

FURNACE. THIS WILL VOID THE MANUFAC-

TURER’S WARRANTY. CONTACT THE SUPPLIER

TO MAKE SURE FERTILIZER IS NOT USED IN THE

SAME TANKS USED TO STORE AND DELIVER LP

GAS.

2.

NOTE:

Order the correct LP conversion kit from the

furnace manufacturer. Furnace conversion to LP gas

must be performed by a qualified installer, service

agency or the gas supplier.

3. All 34

90+ Modulating Gas Furnaces installed at high

elevations above 5,000 ft. require the installation of a

high altitude kit that includes a new model data card for

proper operation.

NOTE:

High altitude operation is limited to a maximum

altitude of 8,000 ft.

All gas piping must comply with the latest NFPA 54

National Fuel Gas Code and all state and local codes.

All electrical wiring must comply with the latest NFPA

70, National Electrical Code and all state and local

codes.

Be sure to check the fuel code of your furnace. The

fuel code is adjacent to the serial number. See the LP

conversion kit index that came with your furnace to

determine the correct LP conversion kit.

4. All altitudes use a 1.10mm orifice. The unique 2% de-

rate requirement per 1000 ft. allows the lower baro-

metric pressure to meet this requirement.

LP CONVERSION

TABLE 12

LP GAS PIPE CAPACITY TABLE (CU. FT./HR.)

Maximum capacity of pipe in thousands of BTU per hour of undiluted liquefied petroleum gases (at 11 inches water

column inlet pressure).

(Based on a Pressure Drop of 0.5 Inch Water Column)

Nominal Length of Pipe, Feet

Iron Pipe

Size, Inches 10 20 30 40 50 60 70 80 90 100 125 150

1/2 275 189 152 129 114 103 96 89 83 78 69 63

3/4 567 393 315 267 237 217 196 182 173 162 146 132

1 1,071 732 590 504 448 409 378 346 322 307 275 252

1-1/4 2,205 1,496 1,212 1,039 913 834 771 724 677 630 567 511

1-1/2 3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787

2 6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496

Example (LP): Input BTU requirement of unit, 120,000

Equivalent length of pipe, 60 ft. = 3/4" IPS required.

!

WARNING

NEVER PURGE A GAS LINE INTO THE COMBUS-

TION CHAMBER. NEVER USE MATCHES, FLAME

OR ANY IGNITION SOURCE FOR CHECKING LEAK-

AGE. FAILURE TO ADHERE TO THIS WARNING CAN

CAUSE A FIRE OR EXPLOSION RESULTING IN

PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

TO CHECK FOR GAS LEAKAGE, USE AN AP-

PROVED CHLORIDE-FREE SOAP AND WATER SO-

LUTION, OR OTHER APPROVED METHOD.

WARNING

!