56

Further, for communicating systems, the above selections

(made with dipswitches SW13, SW14, SW15, and SW16

in legacy mode) can be made via the Econet control cen-

ter.

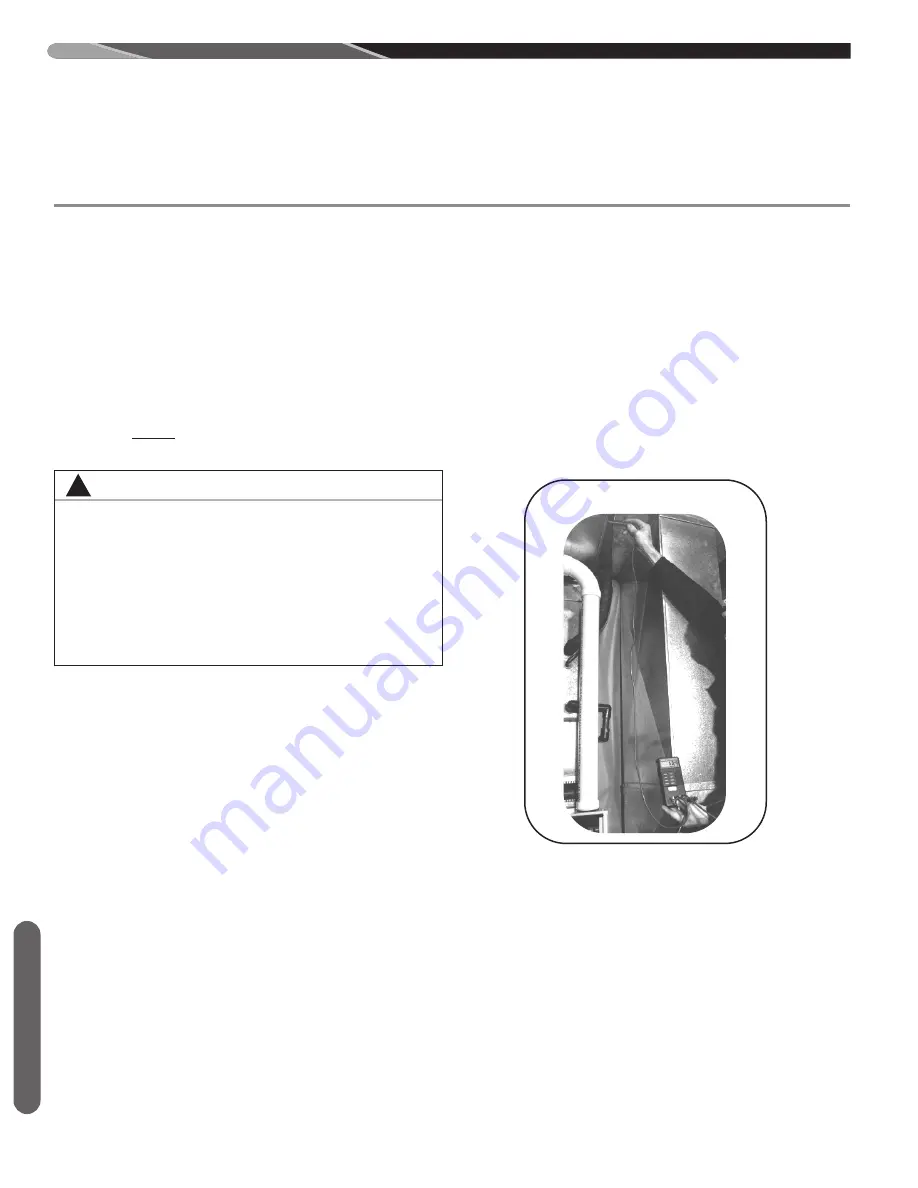

STEP 5: TEMPERATURE RISE

VERIFICATION

AIRFLOW

The importance of proper airflow over the heat exchanger

cannot be over-emphasized.

NOTE

: Where the maximum airflow is expected to be over

1800 CFM,

BOTH

sides or the bottom must be used for

return air.

TEMPERATURE RISE CHECK:

To determine if the airflow is correct, make a temperature

rise check.

1. Insert a thermometer in the supply air duct as close to

the furnace as possible yet out of a direct line-of-site

from the heat exchanger. See Figure 42.

2. Insert a thermometer in the return air duct as close to

the furnace as possible.

3. Operate the furnace for a minimum of 15 minutes in

the gas heat mode at the 100% (max) rate.

4. When the thermometer in the supply air duct stops ris-

ing (approximately 5 minutes), subtract the return air

temperature from the supply air temperature. The dif-

ference is the temperature rise.

5. Compare the measured temperature rise to the ap-

proved temperature rise range listed on the furnace

nameplate. See Figure 43.

6. If the measured temperature rise is above the ap-

proved range, the airflow is too low. Airflow must be in-

creased by speeding up the blower, by removing

restrictions in the duct system or by adding more sup-

ply or return-air duct. If the measured temperature rise

is below the approved range, the airflow is too much.

Use the dipswitches to lower the speed of the blower.

7, Repeat this procedure for low-fire (40% rate).

FURNACE ADJUSTMENTS

Fu

rn

ac

e

Ad

ju

stm

en

ts

FIGURE 42

TEMPERATURE RISE MEASUREMENT

!

CAUTION

IT IS IMPORTANT THAT EACH DUCT SYSTEM BE

SIZED AND INSTALLED FOR THE SPECIFIC APPLI-

CATION BY PROPERLY APPLYING THE APPROPRI-

ATE INDUSTRY-ACCEPTED STANDARD. IF LESS

THAN MINIMUM STANDARDS ARE APPLIED, THE

EQUIPMENT USER COULD EXPECT TO EXPERI-

ENCE HIGHER UTILITY BILLS, MAJOR COMPO-

NENT FAILURE, VARYING DEGREES OF AIR NOISE

OR OTHER UNSATISFACTORY ISSUES, OVER

WHICH THE MANUFACTURER HAS NO CONTROL.