17

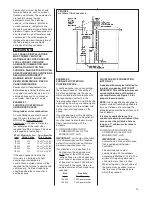

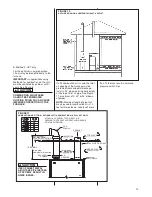

“B-1” VERTICAL VENTING

Type “B-1” vents must be installed in

accordance with the terms of their

listings and the vent manufacturer’s

instructions.

“B-1” vents must be supported and

spaced in accordance with their listings

and the manufacturer’s instructions. All

vents must be supported to maintain

their minimum clearances from

combustible material.

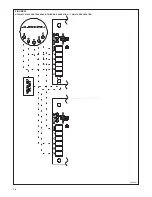

VERTICAL VENTING

Categorized

Furnace Vent

Input

Size Required

50K

3

”

75K

*4

”

100K

*4

”

125K

*5

”

150K

*5

”

*NOTE: All furnaces have a 3” vent

connection as shipped from the factory. A 3”

to 4” or 3” to 5” vent transition is required on

all but the 50,000 BTUH models when

vertically vented or common vented with

metal vent pipes.

THE VENT TRANSITION

CONNECTION MUST BE MADE AT THE

FURNACE VENT EXIT.

It must originate

with an adapter if required, at the furnace

flue collar and terminate either in a listed

cap or roof assembly. When common

venting, the vent connector size may differ

from the above diameters depending on

application. See ANSI Z21.47-1993/CSA-

2.3-M93 or latest edition tables.

VERTICAL VENT SYSTEMS:

1. A gas vent shall terminate above the

roof surface with a listed cap or

listed roof assembly. Gas vents 12

inches in size or smaller with listed

caps shall be permitted to be

terminated in accordance with

Figure 14, provided they are at least

8 feet from a vertical wall or similar

obstruction. All other gas vents shall

terminate not less than 2 feet above

the highest point where they pass

through the roof and at least 2 feet

higher than any portion of a building

within 10 feet.

2. A type B-1 gas vent shall terminate

at least 5 feet in vertical height

above the highest connected

equipment draft hood or flue collar.

3. Must rise

1

/

4

” per foot away from the

furnace on horizontal runs and be

supported with straps or hangers so

it has no sags or dips. Supports at 4

foot intervals and at all elbows are

recommended.

4. The vent connector must be

mechanically fastened to the outlet

collar of the furnace with at least (2)

sheet metal screws except vent

connectors that are B-1 material.

DO NOT CONNECT THIS FURNACE

TO A CHIMNEY USED TO VENT A

SOLID FUEL APPLIANCE (WOOD

OR COAL). VENTING WITH A SOLID

FUEL APPLIANCE CAN LEAD TO

IMPROPER FUNCTIONING OF THE

UNIT, AND DUE TO SOOTING, THE

POSSIBILITY OF FIRE RESULTING

IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

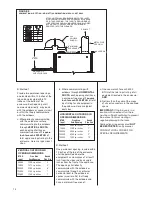

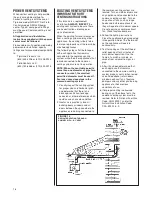

SPECIAL VENT SYSTEMS (SVS)

IMPORTANT:

It is THE FURNACE

MANUFACTURER’s position now that

new installations of any HTPV pipe

used in a category

III

vent application,

including Selkirk’s Selvent™

II

HTPV

product, should cease immediately.

These shall be assembled in

accordance with the manufacturer’s

instructions. See Figure 12.

5. Any angle greater than 45 degrees

from the vertical is considered

horizontal. The total horizontal

distance of a vent plus the horizontal

vent connector serving draft-hood

equipped appliances shall not be

greater than 75 percent of the

vertical height of the vent.

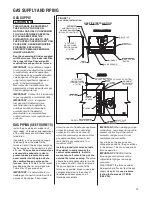

NOTE: Refer to the National Fuel Gas

Code, ANSI Z223.1 and/or the Natural

Gas Installation Code,

CSA-B149.1 & .2.

Single appliance venting of a fan

assisted furnace into a tile-lined

masonry chimney is prohibited. The

chimney must be lined with either Type

B vent or with a listed, single wall,

metal lining system. Reference

National Fuel Gas Code, ANSI Z223.1

and/or the Natural Gas Installation

Code, CSA-B149.1 & .2. See Figure 13

for typical B-1 vent chase.

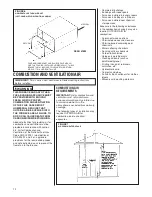

FIGURE 13

TYPICAL VENTING WITH “B-1” VENT

WARNING

!