3.

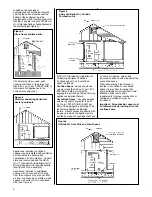

If the electrode position is correct,

the tips should be positioned where

the identifying marks on the gauge

intersect. These two lines

determine:

a.

Correct tip spacing above the

nozzle.

b.

Correct tip spacing ahead of

the nozzle.

The actual distance between

electrodes must be correct /-

1/32".

4.

If the electrode position is not

correct, the electrodes must be

readjusted and rechecked.

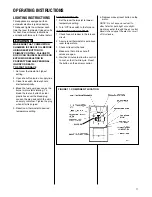

NOZZLE POSITION

1.

Insert the nozzle line/electrode

assembly into the air tube (see

figure 18).

2.

Place the wide section of the

gauge against the burner head

face with 1-1/8" wide end of the

gauge inserted into head.

3.

Slide the nozzle line/electrode as-

sembly forward until the nozzle

touches the gauge.

4.

Secure the adjustable plate on the

burner housing side by tightening

the screw. Then tighten the nut,

securing the nozzle line where it

passes through the side of the

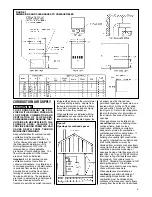

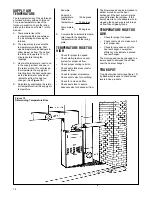

The T231H nozzle, electrode and head

position gauge (see figure 16) is used

to correctly position the electrodes,

nozzle, and head. The gauge is the

best way to ensure that these adjust-

ments are correct.

This gauge is used on the Beckett

model "AFG" burners.

ELECTRODE POSITION

1.

With nozzle line/electrode assem-

bly out of the burner, place the 1-

1/8" wide gauge edge against the

face of the nozzle and between the

electrode tips (see figure 17).

2.

Position the gauge so the center

scribe mark is in line with the

nozzle orifice. (Do not scratch the

nozzle face)

15

housing. This locks the assembly

into position.

The nozzle should now be located

properly with 1-1/8" set back from

the face of the burner head.

NOZZLE CONCENTRICITY

For proper burner operation the nozzle

must be concentric with the burner

head opening.

1.

With the gauge inserted into the

head (see figure 14), the nozzle

orifice should be approximately in

line with the center scribe mark on

the 1-1/8" wide edge of the gauge.

The maximum eccentricity

allowable is identified by the two

outer scribe marks (+/- 1/16").

2.

Rotate the gauge to assure

concentricity in a side-to-side as

well as up-down position.

If the nozzle is not concentric

within allowable limits, it generally

indicates either improper

construction or damaged parts. Do

not use. Replace with a correct as-

sembly.

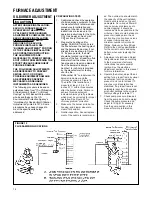

AIR VOLUME

ADJUSTMENTS

The amount of air delivered by the

blower is affected by the resistance of

the ductwork and registers. The factory

adjustment of the blower speed has

been made to suit the average

installation, designed and installed

according to the manuals published by

the National Warm Air Heating and Air

Conditioning Association. The speed of

the direct drive blower can be changed

by rewiring motor leads as described in

the wiring diagrams.

ELECTRODE ADJUSTMENT

Figure 16

T231H

Figure 17

Electrode Adjustment

Figure 18

Nozzle Depth and Concentricity

Summary of Contents for LX2000 Series

Page 27: ...27 PARALLEL WIRING UPFLOW OIL FURNACES SCHEMATIC...

Page 28: ...28 HEATING AND COOLING CONTINUOUS LOW SPEED BLOWER SCHEMATICFIGURE 38...

Page 29: ...29 FIGURE 38 FOR MODELS WITH UTEC 1012 925 INTEGRATED FURNACE CONTROL...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32 CM 898...