31

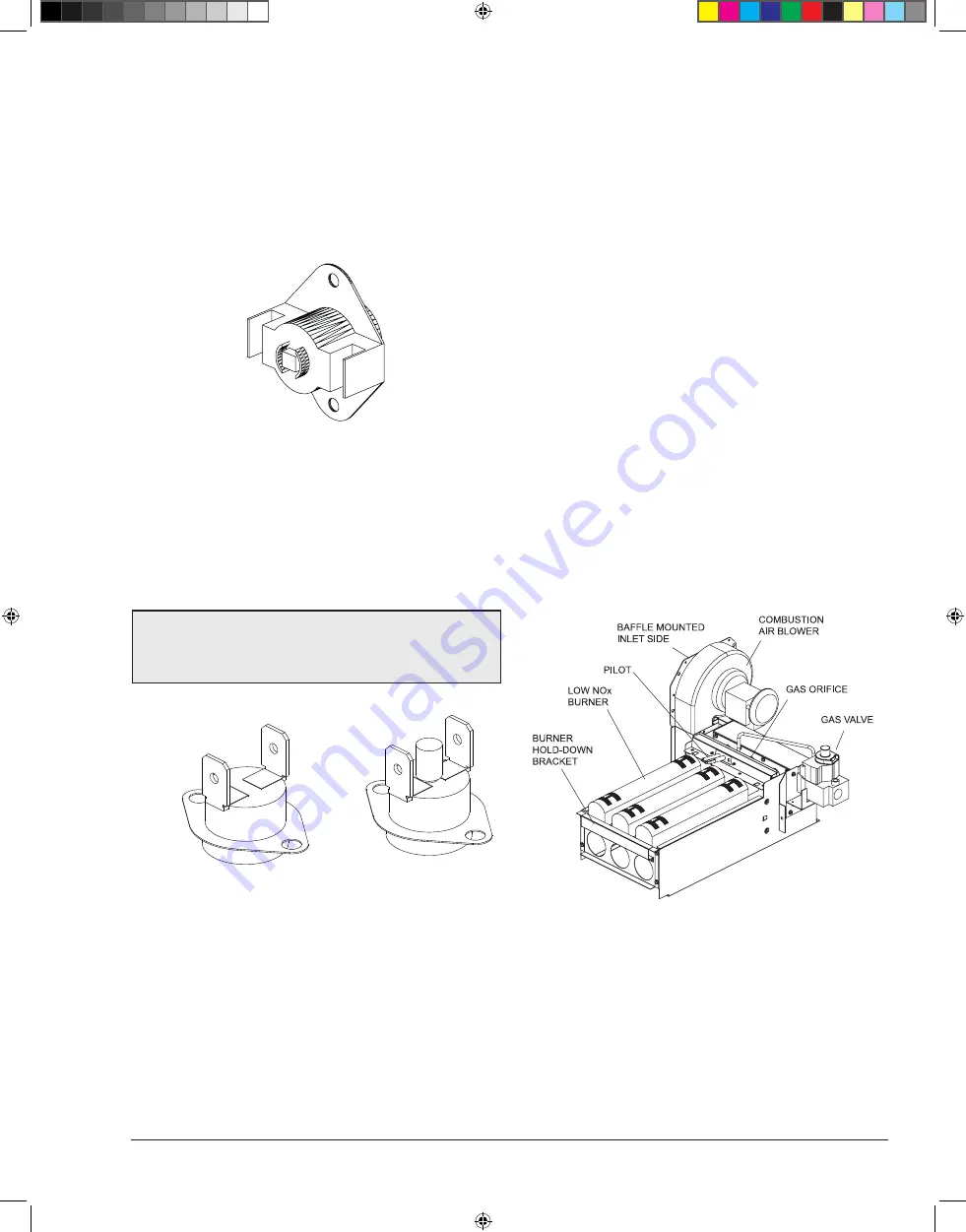

Flame Roll-Out Safety Switch

Heaters are equipped with a thermal cutoff device to

prevent flame roll-out in the event the heat exchanger

becomes blocked. It is a “manual reset” type roll-out

switch that must be reset by a service technician after any

over-temperature conditions have been fixed. Excessive

restriction in the heat exchanger flue passage may cause

the switch to disable the heater.

Figure 53. Flame Roll-out Switch – Manual Reset

High Limits

The heater is equipped with two high limits.

On polymer headers both are automatic and are located in

the inlet/outlet header. Both are set at 135°F (57°C).

On ASME brass header both are located on the inlet/outlet

headers. HL1 is manual reset and set to open at 160°F

(71°C). HL2 is automatic and set to open at 135°F (57°C).

NOTE:

An erratic high limit is often characteristic of

an internal heat exchanger problem, e.g. scale build-up,

defective bypass. Refer to "TROUBLESHOOTING" on

F10669-1

MANUAL RESET

(ASME ONLY)

AUTO RESET

Figure 54. High Limit Switches

High Limit Removal

1. Shut off main electrical power switch to heater.

2.

Remove inlet/outlet sheet metal access panel.

3. Remove defective high limit and replace with the

correct, new high limit.

4.

Replace access panel.

Pilot Safety

The heater employs a pilot safety which closes the main

gas valve within 8/10ths of a second whenever the pilot

flame is interrupted. The pilot flame is automatically lit

when the device is powered. The heater performs its own

safety check and opens the main valve only after the pilot

is proven to be lit.

Burner Tray Removal

1. Shut off main electrical power switch to heater.

2.

Shut off gas upstream of heater.

3. Remove front door.

4.

Disconnect gas line from gas valve.

5.

Remove (2) screws that mount burner tray to the

base of the unit, (2) screws that mount the blower

box to the burner tray, and (1) screw that secures the

anti-rotation bracket to the heater.

6.

Disconnect wires that terminate at gas valve.

7. Unscrew (4) screws that secure the control box.

8. Disconnect pilot wire from the pilot assembly.

9.

Disconnect wire connector from the combustion

blower.

10. Carefully slide out the burner tray assembly.

11. Reverse above procedure to reinstall.

Figure 55. Burner Tray Assembly

Gas Valve Removal

1. Shut off gas supply to the heater. Remove gas piping

to gas valve inlet.

2.

Remove burner tray, following above procedure.

3. Disconnect, pilot tubing from gas valve.

4.

Remove (2) screws that mount anti-rotation bracket

to the burner tray.

6000.592_PoolSpa_LoNOx.indd 31

10/21/2019 2:23:58 PM