18

Installing the System

The circulation pump shall be the Grundfos

model UPS15-58FC/LC, 115 volt or equivalent.

The pump shall be pre-wired with a 6’ line

cord so that it can be plugged directly into

the 115 volt receptacle on the side of the

differential control. Isolation/Drain valves

(No. 6 & 7) must be installed on either side

of the circulating pump so that the pump can

be isolated from the collector loop. Repairs or

routine system maintenance can be completed

without introducing air into the system or

draining the HTF.

The expansion tank shall have a minimum 60

PSIG working pressure and have a total volume

of not less than 2.1 gallons. The expansion tank

shall be Watts Model ET-15 or equal (No. 11).

A high quality thermostatic mixing valve (No.

12) is a required component in all OG-300

certified systems and should be plumbed in line

with brass union connections for ease of future

repair or replacement. The specified mixing

valve shall be the Heatguard model HGBASE

or equal and shall have an operating range

between 95°F and 140°F. The mixing valve

shall be set to 120°F.

The temperatures generated by your system

will vary throughout the year. In the Northern

Hemisphere the water temperature will be

hottest in the spring and summer months while

cooler temperatures are to be expect from

November through March. On sunny days

system temperatures may range between 110ºF

to 180ºF depending upon the season and hot

water demand. The mixing valve described

above blends the hot and cold water supplies

to deliver hot water to your fixtures at a safe,

controlled temperature.

!

WARNING: SCALDING CAN

OCCUR WITHIN FIVE SECONDS

WHEN WATER TEMPERATURES

APPROACH 140ºF. THE MIXING

VALVE SHOULD BE ADJUSTED BY

YOUR CONTRACTOR TO PROVIDE

WATER TO YOUR FIXTURES AT NO

MORE THAN 120ºF.

T

he 3/4" cold water supply line to the solar

storage tank must be insulated with minimum

7/8" X 1/2" pipe insulation to a minimum

distance of 5' behind the storage tank, or to the

wall if closer than 5'.

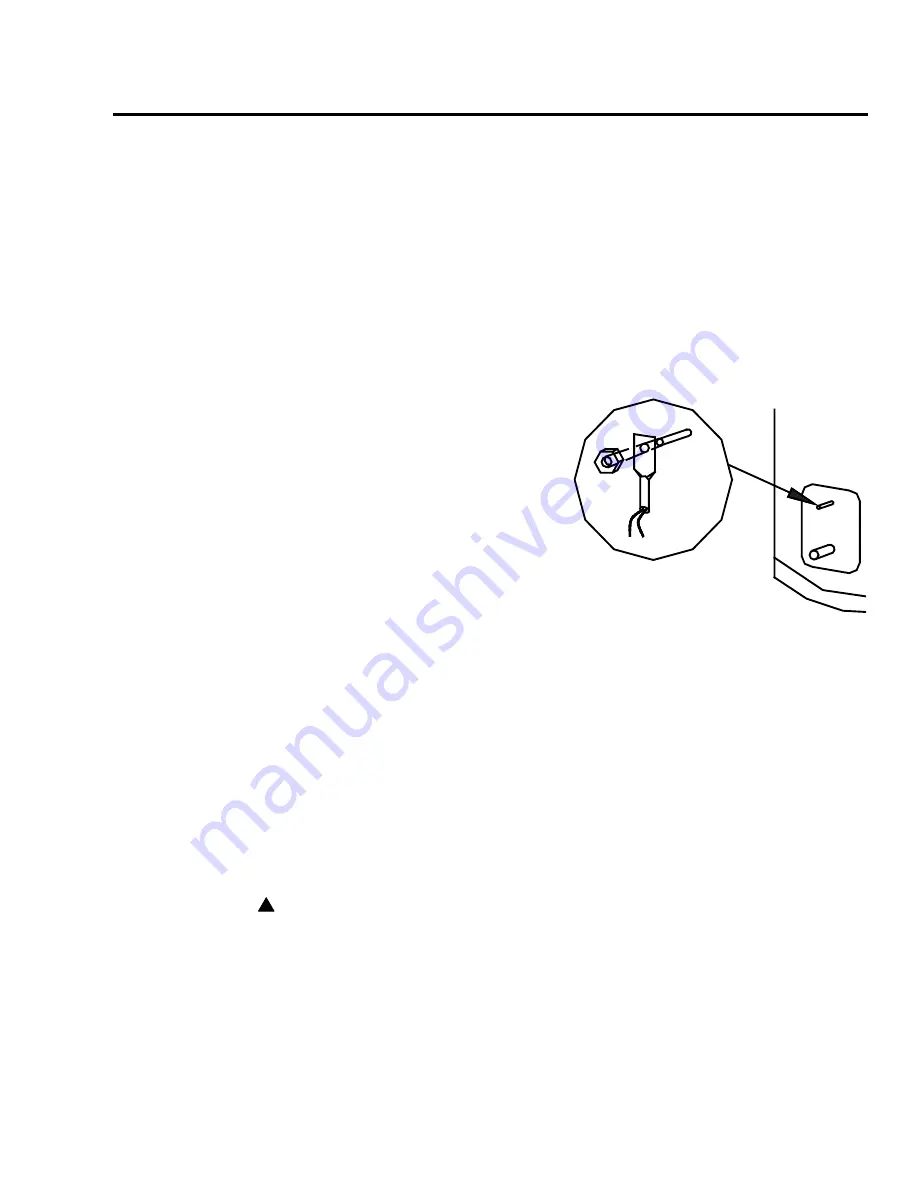

Tank Sensor Placement

Figure 20 details the proper placement of the

solar storage tank sensor. Make sure the sensor

is secured to the threaded stud on the storage

tank with a 10-24 stainless steel nut.

Figure 18 TANK SENSOR

Thoroughly weatherize the wire connections in

accordance with the roof sensor detail above.

Replace the fiberglass insulation batting and

close the access cover.

A properly licensed contractor must make the

gas supply connection to the water heater or

solar storage tank.

The tank must be full of water before heater

is turned on. The water heater warranty does

not cover damage or failure resulting from

operation with an empty or partially empty tank.

We recommend the use of a 115 volt differential

control with a factory installed six foot line

cord. The installation requires one 115 volt

outlet to be installed near the solar storage tank.

Plug the control into the outlet. The circulation

pump line cord is plugged into the receptacle on

the side of the controller.

Figure 20

Tank Sensor