50

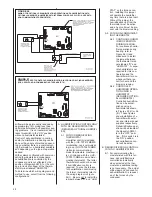

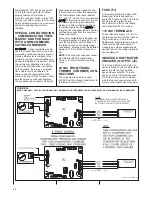

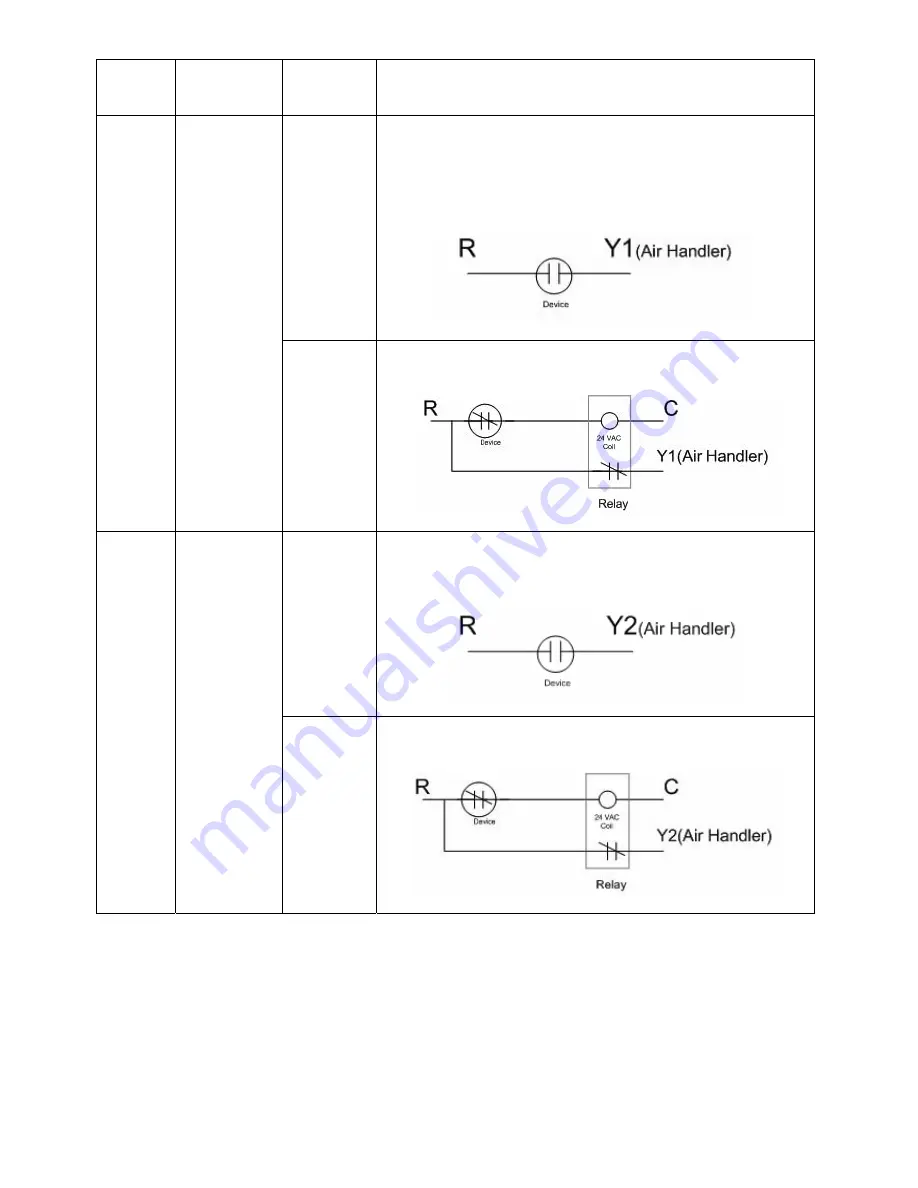

Typical Wiring Accessories for Communicating Residential Systems

The Rheem Serial Communicating (CC2) system allows accessories to be connected to shut down the

system in the event of a fault. Typical devices that can be connected are the drain overflow switch,

smoke detector and freeze protection switch. There are two methods of connecting the switch to the

system depending on the device configuration normally closed or normally open. The blower can run

during a fault or the blower can shut off during a fault depending on how the system is connected.

Please refer to local and/or state codes for installing these devices. The following operation applies only

when BOTH the condenser and thermostat are serial communicating devices. If the condenser is non-

communicating (traditional, legacy 24VAC controlled) this diagram is not valid.

METHOD BLOWER

ACTIVATION

CONTACTS

WIRING CONFIGURATION

NORMALLY

OPEN

When 24 VAC is applied to Y1 at the furnace control in a

communicating system a SYSTEM BUSY message appears on

the thermostat. When the SYSTEM BUSY message appears the

outdoor unit will shut down and the indoor unit will continue

to run at first stage cooling airflow.

A

BLOWER

RUNS

(Y1)

NORMALLY

CLOSED

If the device does not have normally open contacts an

additional relay must be used for proper system operation.

NORMALLY

OPEN

When the device is connected to Y2 and a fault occurs the

blower will shut down. The Y2 input can still be used with

normally open or normally closed contacts.

B

BLOWER

DOES NOT

RUN

(Y2)

NORMALLY

CLOSED

If the device does not have normally open contacts an

additional relay must be used for proper system operation.

Summary of Contents for RGFE

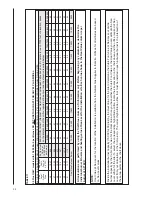

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...