71

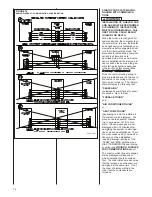

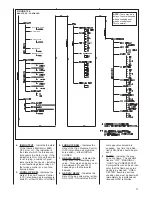

EXAMPLE 3

PROBLEM:

Temperature rise is too low

at 40% firing rate and is too high at

100%.

SOLUTION:

Less airflow is needed to

increase temperature rise at 40% firing

rate and more is needed to decrease

temperature rise at 100%.

1) Set dip switch 4 of SW3 to the “ON”

position to override standard airflow at

40% firing rate. Leave switches 5 and 6

in “OFF” position to decrease airflow by

7.5%.

2) Allow furnace to run for several min-

utes at 40% rate until temperature

probes reach equilibrium.

3) If temperature rise is still lower than

the published range, set switch 6 to the

“ON” position to decrease the airflow

rate from -7.5% to -15% below the

standard value.

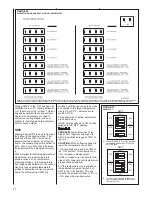

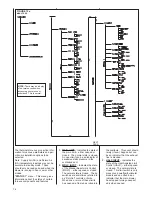

EXAMPLE 2

PROBLEM:

Temperature rise is too low

at 100% firing rate although it is within

the published range at 40% firing rate.

SOLUTION:

Less airflow is needed to

increase temperature rise at 100%.

1) Set dip switch 1 of SW3 to the “ON”

position, which overrides standard air-

flow.

2) Leave switches 2 and 3 in the “OFF”

position to decrease airflow by 7.5%.

3) Allow furnace to run for several min-

utes at 100% rate until temperature

probes reach equilibrium. 4) If the tem-

perature rise is still below the published

range, set switch 3 to the “ON” position.

This will decrease the airflow rate from

7.5% to -15% below the standard value.

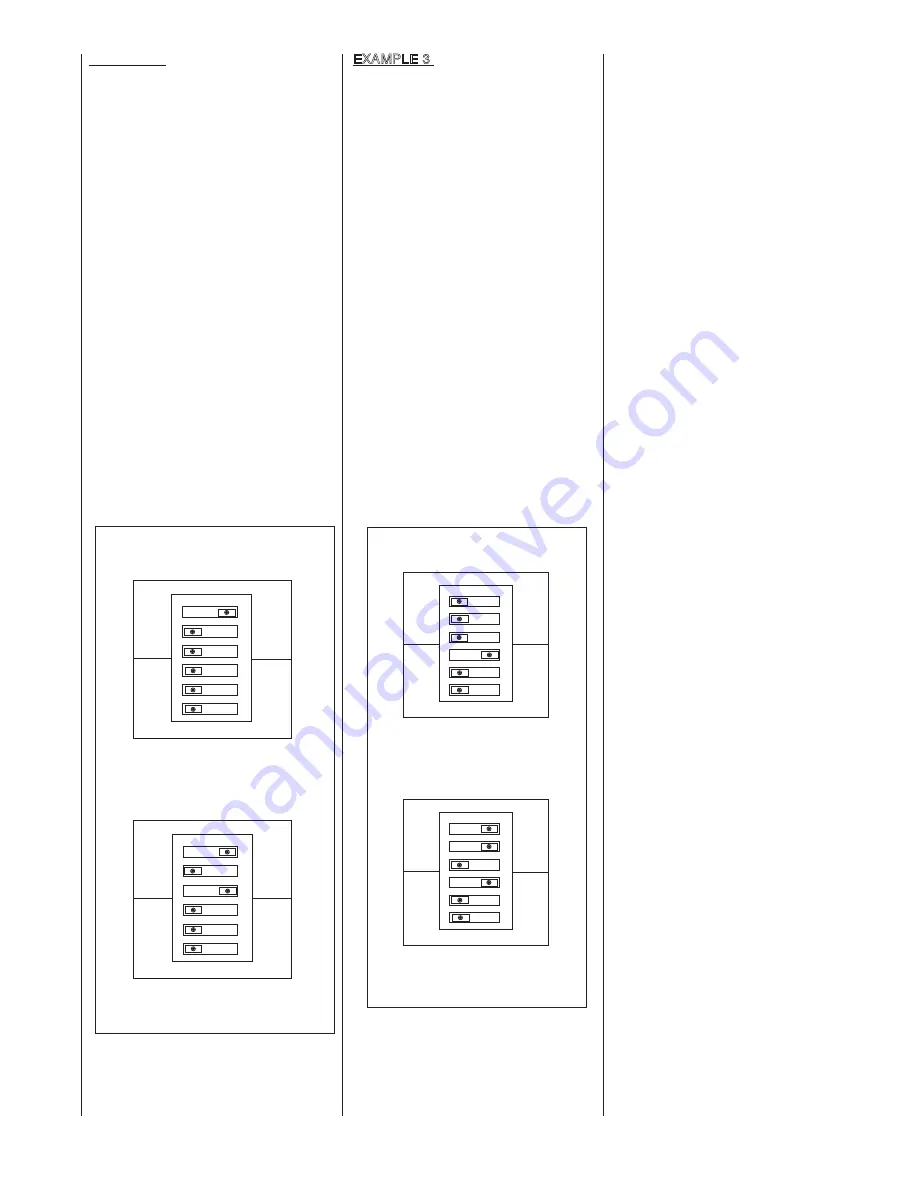

FIGURE 71

EXAMPLE 2

123456

ON

OFF

40%

100%

SW3

STD

--

7.5%

STD

--

7.5%

ADJ

+

15%

ADJ

+

15%

A. Set switch #1 to “ON” position and

leave #2 and #3 in the “OFF” position

to decrease airflow by 7.5% at the

100% fire rate.

123456

ON

OFF

40%

100%

SW3

STD

--

7.5%

STD

--

7.5%

ADJ

+

15%

ADJ

+

15%

B. If -7.5% is not enough, decrease

airflow by setting switch 3 to “ON”

position to give -15%.

FIGURE 72

EXAMPLE 3

123456

ON

OFF

40%

100%

SW3

STD

--

7.5%

STD

--

7.5%

ADJ

+

15%

ADJ

+

15%

A. Set switch #4 to “ON” and leave #5 and

#6 set to “OFF” to decrease airflow by

7.5% at the 40% fire rate. If necessary,

set switch #6 to “ON” to decrease air-

flow by 15%.

123456

ON

OFF

40%

100%

SW3

STD

--

7.5%

STD

--

7.5%

ADJ

+

15%

ADJ

+

15%

B. Set switches #1 and #2 to “ON” and

leave #3 set to “OFF” to increase air-

flow by 7.5% at the 100% fire rate. If

necessary, set switch #3 to “ON” to

increase airflow by 15%.

4) Set dip switches 1 to the “ON”

position to override standard airflow

at 100% firing rate. Set switch 2 to

the “ON” position to increase airflow

by 7.5%.

5) Allow furnace to run for several

minutes at 100% rate until temper-

ature probes reach equilibrium.

6) If temperature rise is still higher

than the published range, set switch

3 to “ON” position to increase the

airflow rate from 7.5% to 15% above

the standard value.

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...