80

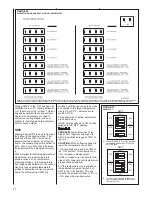

1. COOL AIRFLOW – Displays the

value of the cooling airflow select-

ed. See the section of this manual

titled “DIPSWITCH” under “SW1”

(SW1-1 and SW1-2) for details and

selections.

2. HEAT RISE* – Displays the value

selected for the heat rise (either

nominal or nominal plus ten

degrees F). See the section of

this manual titled “DIPSWITCH”

under “SW1” (SW1-3) for details

and selections.

*ALL TEMPERATURES CAN BE

DISPLAYED ONLY IN FAHREN-

HEIT VALUES

3. HI HEAT ADJ – Displays the value

selected at SW3, positions 4 thru 6.

It is the adjustment of the high heat

rate airflow. See the section of this

manual titled “DIPSWITCH” under

“SW3” (SW3-4 thru SW3-6) for

details and selections.

4. LO HEAT ADJ – Displays the value

selected at SW3, positions 1 thru 3.

It is the adjustment of the low heat

rate airflow. See the section of this

manual titled “DIPSWITCH” under

“SW3” (SW3-1 thru SW3-3) for

details and selections.

5. FAN SPD SELECT – Displays the

fan speed selected. See the sec-

tion of this manual titled “DIP-

SWITCH” under “SW1” (SW3-4) for

details and selections.

6. AC-HP ADJ

– Adjusts the cooling

or heat-pump airflow slightly to

change or adjust the temperature

rise slightly. See the section of this

manual titled “DIPSWITCH” under

“SW1” (SW1-5 and SW1-6) for

details and selections.

7. ON DEMAND DEHUM – Toggles

the dehumidification feature on or

off. See the section of this manual

titled “DIPSWITCH” under “SW2”

(SW2-1) for details and selections.

8. TST MODE OR STG – Displays

the operation configuration based

on the dipswitch selections. These

selections are explained in detail in

the section of this manual titled

“DIPSWITCH” under “SW2” (SW2-

2 and SW2-3). Further description

follows:

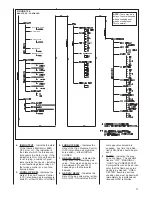

1 STAGING – (SW2-2 = OFF and

SW2-3 = OFF) Represents either

fully modulating operation (when

valid signal is present) or staging

operation when a single stage ther-

mostat is connected.

2 STAGING – (SW2-2 = ON and

SW2-3 = ON) Represents timed

staging operation with a two-stage

thermostat.

40 PRCNT TEST – (SW2-2 = ON

and SW2-3 = OFF) Represents the

mode of operation which will pro-

vide 40% heat rate for any heat call

NOTE: FOR DUAL-FUEL OPERA-

TION, THE SUPPLY AIR SENSOR

MUST BE INSTALLED AND THE

SELECTION FOR THIS SENSOR

SET TO “ON” IN THE “SETUP”

USER MENU UNDER THE SELEC-

TION “SUPPLY AIR SENS” FOR

DUAL-FUEL OPERATION. FAIL-

URE TO INSTALL THE SENSOR

AND TO TURN IT ON IN THE

USER MENUS COULD CAUSE

EXCESSIVE TRIPPING OF THE

PRESSURE LIMIT CONTROLS ON

THE AC SYSTEM.

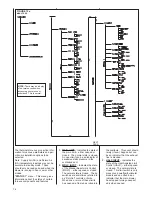

5. FIXED FIRE RATE – This feature

will temporarily fix the gas heating

fire rate to the selection desired.

The selected rate will be applied to

the present heat call only. If there is

no heat call already present when

the selection is attempted, the sys-

tem will not permit the firing rate to

be fixed at the user menu. The firing

rate and blower will be fixed at the

selected rate for the duration of the

existinig heat call or a

m

aximum of

two hours (whichever comes first).

This feature should only be used for

installation, diagnostic, adjustment

and troubleshooting purposes by an

experienced licensed technician.

Selectable firing rates are 40%,

50%, 60%, 70%, 75%, 80%, 85%,

90% and 100%.

6. RESET ALL DFLTS

– This selec-

tion restores all items in the

“SETUP” menu to the factory default

selections. If “yES” is selected, all

settings in this menu will be lost.

NOTE:

When faults are cleared in

the furnace “SETUP” user menu,

the continuous fan CFM will also be

restored to the factory default set-

ting. (See Continuous Fan

Operation in Communicating Mode.)

BELOW USER MENU IS USED FOR

NON-COMMUNICATING SYSTEMS

ONLY

“DIPSWITCH”

menu – This menu per-

mits viewing of the dipswitch selections.

It is a way to read the dipswitch selec-

tions without the need of translating the

settings manually.

Note: The “DIPSWITCH” menus will not

be displayed at the thermostat. They

are invisible to the thermostat and can

not be displayed. These menus can

only be viewed with the field service

tool. The reason is that dipswitch selec-

tions do not generally affect operation of

the furnace when using the communi-

cating mode of operation.

NOTE:

The integrated furnace control

does not recognize switch setting

changes while energized. To change

settings, remove power to the board by

turning off the disconnect or switch to

the furnace control or removing power

at the breaker, make changes, then

return power.

– regardless of the rate transmit-

ted by the thermostat. This

mode ends automatically after

the first 60 minutes of operation

after power-up.

100 PRCNT TEST – (SW2-2 =

OFF and SW2-3 = ON)

Represents the mode of opera-

tion which will provide 100%

heat rate for any heat call –

regardless of the rate transmit-

ted by the thermostat. This

mode ends automatically after

the first 60 minutes of operation

after power-up.

9. AC HP STG MULT – This allows

for adjustment to the airflow for

low-stage of cooling and heat-

pump operation. See the sec-

tion of this manual titled “DIP-

SWITCH” under “SW2” (SW2-4)

for details and selections.

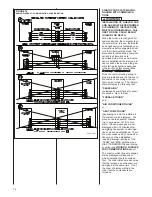

DUAL-FUEL OPERATION IN COM-

MUNICATING MODE

Systems configured for dual-fuel

operation will include a communicat-

ing condenser with a reversing

valve. Dual-fuel systems will display

“

HP” for Heat-Pump heat operation

at the furnace control’s (I.F.C.) dual

seven-segment displays. During

defrost mode, “

dF” will be displayed.

All other codes apply.

The balance point can be adjusted

at the thermostat for optimal opera-

tion. The balance point is the point

below which gas heat will be used

and above which heat-pump heat

will be used.

For dual-fuel systems, to protect

equipment, the supply air sensor

must be installed. When the supply

air sensor is properly installed and

the system is in

defrost

mode, the

gas heat will only operate when the

outlet air is below 110°F. When the

outlet air exceeds 110°F, the gas

valve is turned off and the Air

Circulating Blower (ACB) continues

to run. When the supply air tempera-

ture reaches 95°F, the gas heat will

again be turned on. This cycle will

continue until the call for defrost has

ended.

NOTE:

FOR DUAL-FUEL OPERA-

TION, THE SUPPLY AIR SENSOR

MUST BE INSTALLED AND THE

SELECTION FOR THIS SENSOR

SET TO “ON” IN THE “SETUP”

USER MENU UNDER THE SELEC-

TION “SUPPLY AIR SENS” FOR

DUAL-FUEL OPERATION. FAIL-

URE TO INSTALL THE SENSOR

AND TO TURN IT ON IN THE

USER MENUS COULD CAUSE

EXCESSIVE TRIPPING OF THE

PRESSURE LIMIT CONTROLS ON

THE AC SYSTEM.

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...