48

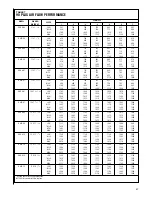

TABLE 8

90 PLUS AIR FLOW PERFORMANCE – RGRJ & RGTJ MODELS

CFM @ ESP

MODEL

BLOWER/

SPEED

MOTOR HP

.1

.2

.3

.4

.5

.6

.7

RGRJ-04

11 x 7 /

1

/

2

LOW

805

780

760

720

685

645

605

MED-LO

920

885

850

810

775

730

690

MED-HI

1140

1110

1085

1045

1010

950

890

HIGH

1360

1320

1280

1235

1195

1140

1080

RGTJ-04

11 x 7 /

1

/

2

LOW

820

790

760

725

690

650

610

MED-LO

930

890

850

815

785

750

720

MED-HI

1150

1120

1090

1045

1002

950

900

HIGH

1414

1365

1320

1270

1220

1165

1115

RGRJ-06

11 x 7 /

1

/

2

LOW

880

845

815

790

760

715

670

MED

1060

1025

990

960

925

880

835

HIGH

1260

1215

1175

1135

1100

1040

985

RGTJ-06

11 x 7 /

1

/

2

LOW

910

885

860

815

770

725

680

MED

1115

1080

1045

1005

965

920

875

HIGH

1365

1315

1270

1225

1180

1125

1070

RGRJ-07

11 X 7 /

1

/

2

LOW

880

850

825

785

750

702

655

MED

1090

1050

1010

970

925

875

825

HIGH

1300

1255

1210

1160

1110

1055

1005

RGTJ-07

11 X 7 /

1

/

2

LOW

890

860

835

790

750

705

660

MED

1100

1060

1025

980

940

890

845

HIGH

1340

1295

1250

1200

1150

1090

1025

RGRJ-07

12 X 7 /

1

/

2

LOW

1185

1160

1140

1115

1095

1065

1040

MED

1405

1375

1350

1310

1270

1235

1195

HIGH

1595

1560

1525

1480

1440

1380

1325

RGTJ-07

12 X 7 /

1

/

2

LOW

1105

1095

1080

1050

1030

1010

990

MED

1290

1275

1260

1220

1195

1170

1140

HIGH

1480

1435

1415

1390

1370

1300

1255

RGRJ-07

12 X 7 /

3

/

4

LOW

1405

1375

1350

1310

1270

1235

1195

MED

1595

1560

1525

1480

1440

1380

1325

HIGH

1835

1780

1730

1675

1625

1555

1480

RGTJ-07

12 X 7 /

3

/

4

LOW

1290

1275

1260

1220

1195

1170

1140

MED

1480

1435

1415

1390

1370

1300

1255

HIGH

1705

1665

1615

1570

1540

1475

1400

RGRJ-09

12 X 11 /

1

/

2

LOW

1235

1210

1180

1150

1120

1075

1035

MED

1490

1465

1445

1405

1375

1315

1255

HIGH

1720

1670

1620

1600

1580

1520

1460

RGTJ-09

12 X 11 /

1

/

2

LOW

1155

1125

1100

1080

1060

1000

940

MED

1420

1400

1380

1365

1350

1260

1175

HIGH

1605

1575

1550

1560

1570

1480

1395

RGRJ-09

12 X 11 /

3

/

4

LOW

1490

1465

1445

1405

1375

1315

1255

MED

1720

1670

1620

1600

1580

1520

1460

HIGH

2100

2050

2000

1955

1910

1825

1745

RGTJ-09

12 X 11 /

3

/

24

LOW

1420

1400

1380

1365

1350

1260

1175

MED

1605

1575

1550

1560

1570

1480

1395

HIGH

2005

1965

1930

1890

1850

1765

1680

RGRJ-10

12 X 11 /

1

/

2

LOW

1230

1205

1180

1155

1130

1090

1050

MED

1490

1445

1405

1375

1350

1295

1240

HIGH

1710

1665

1620

1580

1540

1475

1410

RGTJ-10

12 X 11 /

1

/

2

LOW

1180

1150

1120

1100

1080

1025

970

MED

1460

1425

1390

1375

1360

1280

1200

HIGH

1680

1645

1615

1585

1560

1490

1420

RGRJ-10

12 X 11 /

3

/

4

LOW

1490

1445

1405

1375

1350

1295

1240

MED

1710

1665

1620

1580

1540

1475

1410

HIGH

2010

1955

1900

1855

1810

1710

1610

RGTJ-10

12 X 11 /

3

/

4

LOW

1460

1425

1390

1375

1360

1280

1200

MED

1680

1645

1615

1585

1560

1490

1420

HIGH

2055

2000

1940

1880

1820

1745

1675

RGRJ-12

11 X 10 /

1

/

2

LOW

1320

1305

1290

1260

1230

1185

1140

MED

1610

1580

1555

1515

1475

1415

1355

HIGH

1870

1820

1775

1715

1

1590

1520

RGTJ-12

11 X 10 /

1

/

2

LOW

1285

1250

1215

1235

1260

1230

1200

MED

1590

1565

1540

1505

1

1425

1375

HIGH

1840

1820

1800

1750

1700

1645

1590

RGRJ-12

11 X 10 /

3

/

4

LOW

1610

1580

1555

1515

1475

1415

1355

MED

1870

1820

1775

1715

1660

1590

1520

HIGH

2115

2050

1990

1945

1900

1795

1690

RGTJ-12

11 X 10 /

3

/

4

LOW

1590

1565

1540

1505

1475

1425

1375

MED

1840

1820

1800

1750

1700

1645

1590

HIGH

2315

2250

2185

2110

2040

1965

1890

* Heating speed for cooling applications

NOTE: Units tested with filters in place.

Summary of Contents for RGRA SERIES

Page 62: ...62...

Page 63: ...63...

Page 64: ...64 Rheem Manufacturing Company Air Conditioning Division Fort Smith Arkansas CM 1197...