44

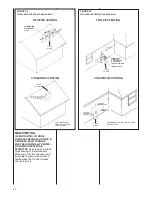

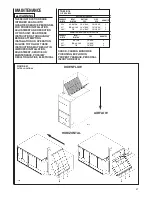

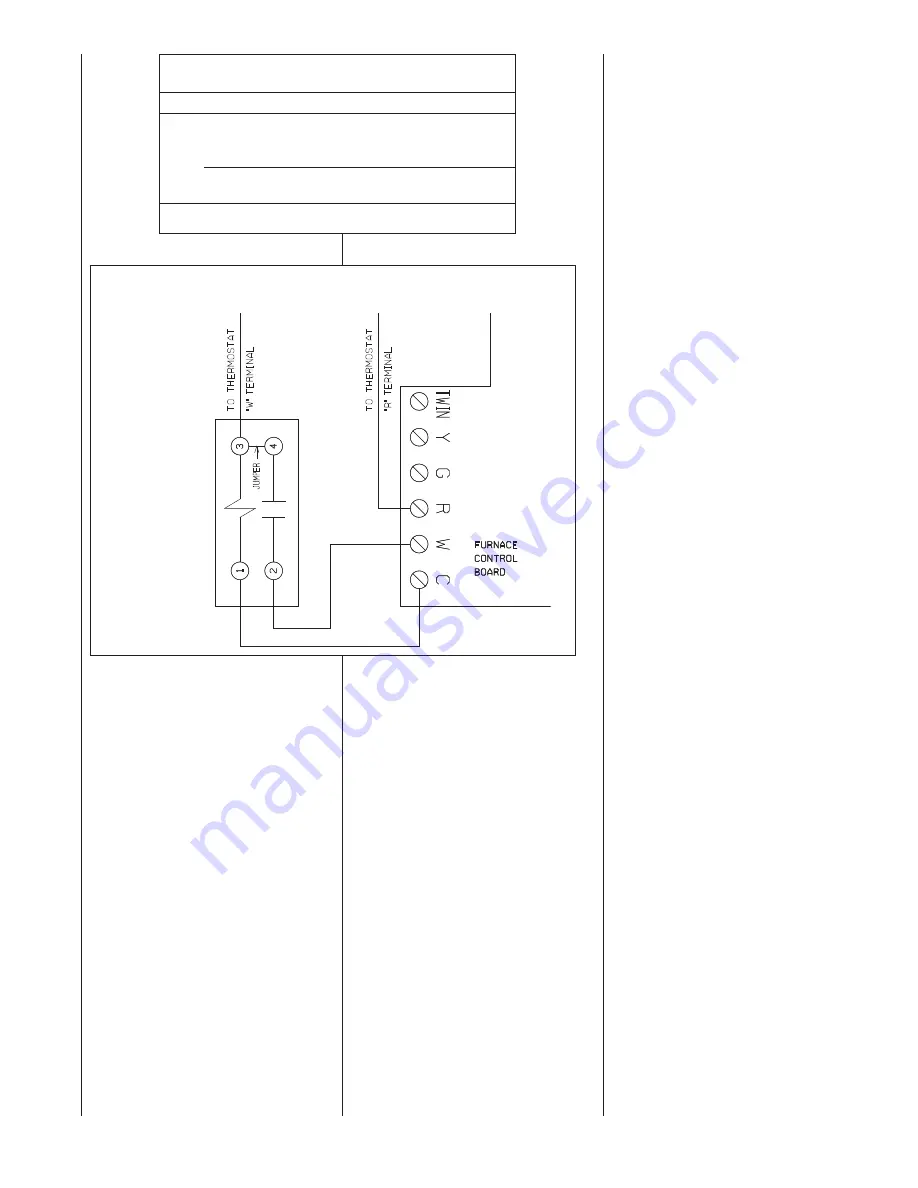

FURNACE TWINNING

INSTALLATIONS

NOTE:

Run furnaces as individual

furnaces before trying to twin or when

troubleshooting.

Twinning operation of two furnaces,

installed side-by-side, connected by a

common duct system with main power

supplied by the same source, and

controlled by a common thermostat can

be done with the UT Electronic Controls

1095-204 integrated control boards.

➀

Only twin identical furnaces with

identical control boards.

➁

Furnaces must have same heating

and blower capacity.

➂

Only bottom returns can be used.

(Upflow models only)

➃

No more than two furnaces (a pair)

can share the same supply and

return.

NOTE:

Duct system must be adequate

to provide correct airflow to each

furnace for supply and return.

IMPORTANT:

Twinning furnaces must

operate off the same phase of power.

It should be noted that both blowers will

run simultaneously when there is a call

for heating, cooling or fan.

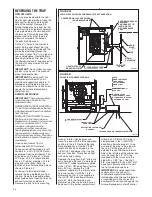

The status LED will display blink code 5

if twinning is not set up properly (refer to

Troubleshooting diagram in the back of

this manual).

IMPORTANT:

Only two furnaces on a

single thermostat.

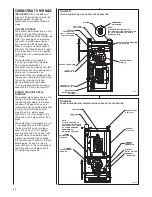

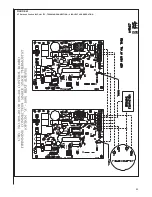

UT ELECTRONIC CONTROLS

1095-201 or 204

TWO-STAGE TWINNING OPERATION

USING A SINGLE-STAGE

THERMOSTAT

A two-stage thermostat will give the

most optimum performance. The

furnace (when twinned) can operate

using a single-stage thermostat.

OPTION A:

To run both units together

as a single-stage furnace with

NO

staging (100% high heat always) wire

the two furnaces together as shown in

Figure 43.

Both controls must have jumper P6 in

the “TWIN” position (see Figure 48).

Both controls must have jumper P7 in

the “5” or “7” position (see Figure 48).

OPTION B:

Both controls must have

jumper P6 in the “TWIN” position (see

Figure 48).

Both controls must have jumper P7 in

the “5” or “7” position (see Figure 48).

For the first fire or twelve minutes of

operation, the furnace will run at low

fire. If the thermostat does not satisfy

in fire or twelve minutes, the furnaces

will automatically switch to high fire

and will run on high fire until the

thermostat is satisfied. See Figure 43

for the wiring diagram for this

configuration.

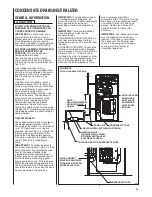

TWO-STAGE OPERATION

(See Figure 45)

a. Control board "ONE" is on

furnace connected to the

thermostat.

b. The 24 VAC supply to both

control boards must be in

phase with each other.

c. Connect the "C," "W1," “W2,”

“Y,” and "TWIN" terminals to

counterparts on each control.

d. Both control boards must have

jumper P6 in the “TWIN”

position (see Figure 48).

Both controls must have

jumper P7 in the “NONE”

position (see Figure 48).

FIGURE 42

ISOLATION RELAY

ST-A0804-01

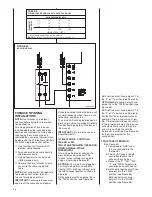

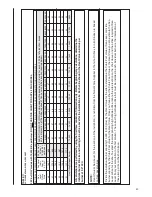

TABLE 9

FIELD WIRE SIZE FOR 24 VOLT CONTROL CIRCUITS

SOLID COPPER WIRE - AWG

3.0

16

14

12

2.5

16

14

12

2.0

18

16

14

50

100

150

LENGTH OF RUN - FEET

➀

➀

Wire length equals twice the run distance

NOTE:

Do not use 24 volt control wiring smaller than No. 18.

T

H

E

R

M

O

S

T

A

T

L

O

A

D

-

A

M

P

S

Summary of Contents for RGRK SERIES

Page 41: ...41 FIGURE 39 TYPICAL MANIFOLD PRESSURE READING...

Page 45: ...45 FIGURE 43 UT Electronic Controls 1095 201 IFC TWINNING CONNECTION SINGLE STAGE OPERATION...

Page 60: ...60 FIGURE 53 TROUBLESHOOTING CHART or IFC not properly grounded Go To Next Page...

Page 61: ...61 FIGURE 53 TROUBLESHOOTING CHART CONTINUED...

Page 62: ...62 FIGURE 54 WIRING DIAGRAM...

Page 63: ...63...

Page 64: ...64 CM 0510...