16

• No perimeter supply flanges are provided. If a full perimeter supply duct is used, it is

the responsibility of the installer to provide duct flanges as needed, to secure and seal

the supply duct to prevent air leakage and the sweating that will result.

• Apply caulking around all cabinet penetrations such as power wires, control wires,

refrigerant tubing and condensate line where they enter the cabinet. Seal the power

wires on the inside where they exit conduit opening. Sealing is required to prevent air

leakage into the unit which can result in condensate forming inside the unit, control

box, and on electrical controls. Take care not to damage, remove or compress insula-

tion when applying the caulk.

• In some cases, the entire air handler can be wrapped with insulation. This can be

done as long as the unit is completely enclosed in insulation, sealed and service

access is provided to prevent accumulation of moisture inside the insulation wrap.

• An auxiliary overflow pan is recommended to protect the structure from excessive

cabinet sweating or a restricted coil drain line. (See Section 3.3)

• If an electric heater kit is installed, be sure the breaker or disconnect cover is sealed

tightly to the door panel.

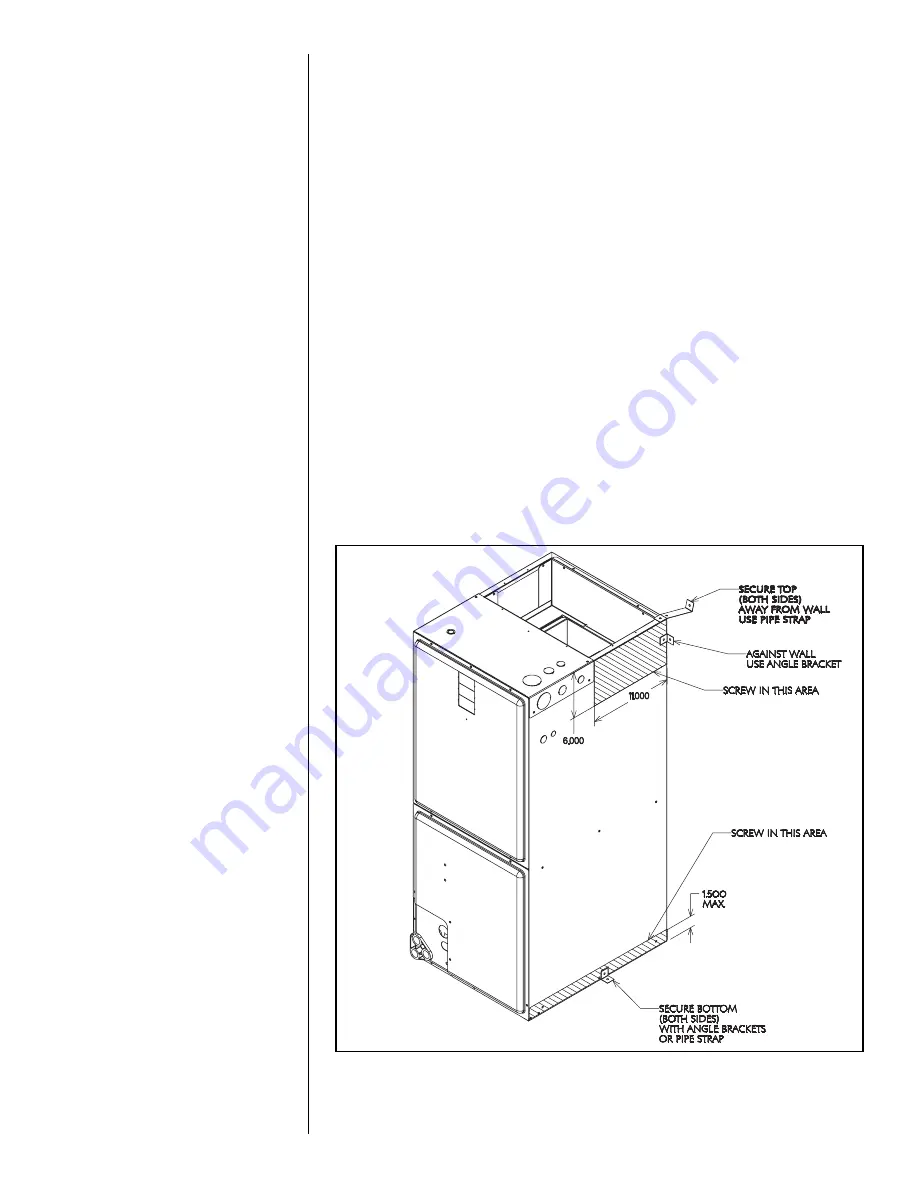

3.2.4 INSTALLATION IN MOBILE/MANUFACTURED HOMES

1. Air handler must be secured to the structure using “L” brackets or pipe strap.

2. Allow a minimum of 24 inches (610 mm) front clearance required to access doors.

3. Recommended method for securing air handler:

A. If air handler is against the wall, secure top of air handler to wall stud using two

16ga thick angle brackets one on each side. Attach brackets with No. 10 self-tap-

ping

1

⁄

2

long screws to air handler and use

5

⁄

16

lag screws 1

1

⁄

2

long to wall stud.

Secure bottom of unit with two 16ga “L” brackets with No. 10 self-tapping

1

⁄

2

long

screws to air handler and use

5

⁄

16

lag screws 1

1

⁄

2

long to floor.

B. If air handler is away from wall attach pipe strap to top of air handler using No. 10

1

⁄

2

long self-tapping screws on both sides. Angle strap down and away from back

of air handler, remove all slack, and fasten to wall stud of structure using

5

⁄

16

lag

screws 1

1

⁄

2

long. Secure bottom of unit with two 16ga “L” brackets with No. 10

self-tapping screws to air handler and use

5

⁄

16

lag screws 1

1

⁄

2

long to floor.

FIGURE 8

ST-A-1193-01