17

jurisdiction. USE COPPER WIRE

OnLY. Provide separate branch electric

circuit with field supplied disconnect

switch.

Location of disconnect switch to be in

clear site, accessible and in close

proximity to the unit.

Correct polarity MUST be maintained for

115 V wiring. If polarity is incorrect, unit

will nOT operate.

Use a separate fused branch electrical

circuit containing a properly sized fuse

or circuit breaker. Run this circuit directly

from the main switch box to an electrical

disconnect that is readily accessible and

located near the air handler. Connect

from the electrical disconnect to the

junction box on the left side of the air

handler, inside the blower compartment.

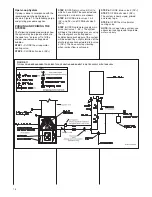

For the proper connection, refer to the

appropriate wiring diagram located on

the inside cover of the air handler

control box and in these instructions.

The electrical junction box may be

moved to the right side if necessary. A

knockout is provided. Seal the opposite

hole with plug provided.

Make all electrical connections in

accordance with the latest edition of the

national Electrical Code, AnSI/nFPA70

and local codes having jurisdiction.

These may be obtained from:

national Fire Protection

Association, Inc.

Batterymarch Park

Quincy, MA 02269

CSA - International

178 Rexdale Blvd.

Etobicoke (Toronto), Ontario

Canada M9W, 1R3

ELECTRICAL WIRING

TURN OFF ELECTRIC POWER AT

FUSE BOX OR SERVICE PANEL

BEFORE MAkING ANY

ELECTRICAL CONNECTIONS.

FAILURE TO DO SO CAN CAUSE

ELECTRICAL SHOCk RESULTING

IN PERSONAL INJURY OR DEATH.

THE CABINET MUST HAVE AN

UNINTERRUPTED GROUND

ACCORDING TO THE LATEST

EDITION OF THE NATIONAL

ELECTRICAL CODE (NEC), ANSI/

NFPA70- OR IN CANADA, THE

CANADIAN ELECTRICAL CODE,

CSA-C221 OR LOCAL CODES

THAT APPLY. DO NOT USE GAS

PIPING AS AN ELECTRICAL

GROUND. A GROUND SCREW IS

PROVIDED IN THE JUNCTION

BOX. FAILURE TO DO SO CAN

CAUSE ELECTRICAL SHOCk,

RESULTING IN PERSONAL

INJURY OR DEATH.

THIS AIR HANDLER IS EqUIPPED

WITH A BLOWER DOOR SAFETY

SWITCH. DO NOT DISABLE THIS

SWITCH. FAILURE TO FOLLOW

THIS WARNING CAN RESULT IN

ELECTRICAL SHOCk, PERSONAL

INJURY OR DEATH.

IMPORTANT:

The air handler must

be installed so that the electrical

components are protected from water

(condensate).

Before proceeding with the electrical

connections, be certain that the

voltage, frequency and phase

corresponds to that specified on the

air handler rating plate. For single air

handler application, maximum over-

current protection is 15 amperes.

IF A DISCONNECT SWITCH IS TO

BE MOUNTED ON THE UNIT,

SELECT A LOCATION WHERE A

DRILL OR FASTENER WILL NOT

CONTACT ELECTRICAL OR

HYDRONIC COMPONENTS.

ELECTRICAL SHOCk CAN CAUSE

PERSONAL INJURY OR DEATH.

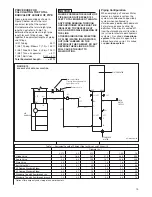

NOTE:

Prior to making any electrical

connections, ensure that supply

voltage, frequency, and phase are as

specified on unit rating plate.

Check to ensure that the existing

electrical service is adequate to

handle the additional load imposed by

the Hydronic Air Handler. Refer to

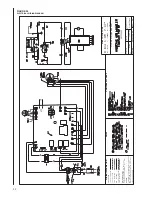

unit wiring diagram for proper

electrical connections.

All electrical connections MUST

comply with nEC and any other local

codes or ordinances having

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

THERMOSTAT

The room thermostat must be com-

patible with the integrated air handler

control on the air handler. Generally,

all thermostats that are not of the

“current robbing” type are compatible

with the integrated air handler control.

The low voltage wiring should be

sized as shown (see Figures 12 and

13, 12A and 13A).

NOTE:

Do not use 24 volt control

wiring smaller than no. 18 AWG.

Install the room thermostat in

accordance with the instruction sheet

packed in the box with the thermostat.

Run the thermostat lead wires inside

the blower compartment and connect

to low voltage terminals as shown on

the wiring diagram. never install the

thermostat on an outside wall or

where it will be influenced by drafts,

concealed hot or cold water pipes or

ducts, lighting fixtures, radiation from

fireplace, sun rays, lamps, televisions,

radios or air streams from registers.

Refer to instructions packed with the

thermostat for “heater” selection or

adjustment.

ACCESSORIES

FIELD-INSTALLED

OPTION ACCESSORIES

ELECTRONIC AIR CLEANER

Line voltage power can be supplied

from the screw terminal “EAC” and a

line voltage neutral screw terminal on

the control board. This will power the

electronic air cleaner whenever the

circulating air blower is in operation.

Expansion Tank:

Expansion tank for closed systems

air separator – TACO Model 49-075.

Summary of Contents for RW1P

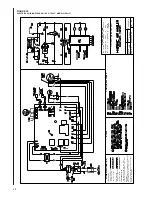

Page 29: ...29 FIGURE 21 ELECTRICAL WIRING DIAGRAM PSC MOTORS RW1P...

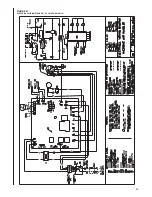

Page 32: ...32 FIGURE 24 ELECTRICAL WIRING DIAGRAM...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36 CM 0617...