2

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE

UNDERWRITERS LABORATORY

(UL) CERTIFICATION OR THESE

INSTRUCTIONS, CAN RESULT IN

UNSATISFACTORY OPERATION

AND/OR DANGEROUS CONDI-

TIONS AND ARE NOT COVERED

BY THE UNIT WARRANTY.

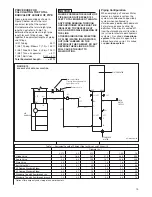

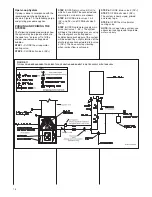

DUCT LEAkS CAN CREATE AN

UNBALANCED SYSTEM AND

DRAW POLLUTANTS SUCH AS

DIRT, DUST, FUMES AND ODORS

INTO THE HOME CAUSING

PROPERTY DAMAGE. FUMES

AND ODORS FROM TOXIC,

VOLATILE OR FLAMMABLE

CHEM I CALS, AS WELL AS AUTO-

MOBILE EXHAUST AND CARBON

MONOXIDE (CO), CAN BE DRAWN

INTO THE LIVING SPACE

THROUGH LEAkING DUCTS AND

UNBALANCED DUCT SYSTEMS

CAUSING PERSONAL INJURY OR

DEATH (SEE FIGURE 2).

• IF AIR-MOVING EqUIPMENT OR

DUCTWORk IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EqUIPMENT AND DUCT MUST

BE SEALED TO LIMIT THE

MIGRATION OF TOXIC FUMES

AND ODORS INCLUDING CAR -

BON MONOXIDE FROM

MIGRATING INTO THE LIVING

SPACE.

• IF AIR-MOVING EqUIPMENT OR

DUCTWORk IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH

AS WATER HEATERS OR

BOILERS - ALL JOINTS, SEAMS,

AND OPENINGS IN THE EqUIP -

MENT AND DUCT MUST ALSO

BE SEALED TO PREVENT

DEPRESSURIZATION OF THE

SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING

CARBON MONOXIDE INTO THE

LIVING SPACE.

IN COMPLIANCE WITH

RECOGNIZED CODES, IT IS

RECOMMENDED THAT AN

AUXILIARY DRAIN PAN BE

INSTALLED UNDER ALL

EVAPORATOR COILS AND UNITS

CONTAINING EVAPORATOR

COILS AND AIR HANDLERS USED

WITH EVAPORATOR COILS THAT

ARE LOCATED IN ANY AREA OF

A STRUCTURE WHERE DAMAGE

TO THE BUILDING OR BUILDING

CONTENTS MAY OCCUR AS A

RESULT OF AN OVERFLOW OF

THE COIL DRAIN PAN, A

STOPPAGE IN THE PRIMARY

CONDENSATE DRAIN PIPING OR

ANY WATER LEAk POTENTIAL

FROM THE AIR HANDLER.

!

WARNING

NOTICE

APPLICATION OF THIS HYDRONIC

AIR HANDLER SHOULD BE

INDOORS. SPECIAL ATTENTION

SHOULD BE GIVEN TO UNIT

SIZING AND PIPING, FILLING, AND

PURGING.

NOTICE

FAILURE TO FOLLOW THIS

CAUTION MAY RESULT IN

PERSONAL INJURY. SHEET

METAL PARTS MAY HAVE

SHARP EDGES OR BURRS. USE

CARE AND WEAR APPROPRIATE

PROTECTIVE CLOTHING.

CAUTION

NOTICE

SAFETY INFORMATION

WHEN AN AIR HANDLER IS

INSTALLED SO THAT SUPPLY

DUCTS CARRY AIR CIRCULATED

BY THE AIR HANDLER TO AREAS

OUTSIDE THE SPACE

CONTAINING THE AIR HANDLER,

THE RETURN AIR SHALL ALSO

BE HANDLED BY DUCT(S)

SEALED TO THE AIR HANDLER

CASING AND TERMINATING

OUTSIDE THE SPACE

CONTAINING THE AIR HANDLER.

INSTALLATION MUST COMPLY

WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

• AIR HANDLER OPERATING

UNDER THERMOSTATIC

CONTROL;

• RETURN AIR DUCT SEALED TO

THE AIR HANDLER;

• AIR FILTERS IN PLACE;

• RETURN AIR TEMPERATURE

MAINTAINED BETWEEN 55°F

(13°C) AND 80°F (27°C); AND

• CLEAN AIR HANDLER, DUCT

WORk AND COMPONENTS

UPON SUBSTANTIAL

COMPLETION OF THE

CONSTRUCTION PROCESS,

AND VERIFY AIR HANDLER

OPERATING CONDITIONS

INCLUDING FLOW RATE AND

TEMPERATURE RISE,

ACCORDING TO THE

INSTRUCTIONS.

!

WARNING

!

WARNING

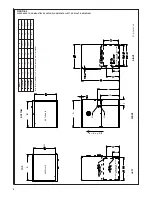

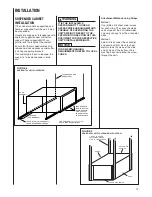

HORIZONTAL UNITS MUST BE

CONFIGURED FOR RIGHT HAND

AIR SUPPLY OR LEFT HAND AIR

SUPPLY. HORIZONTAL DRAIN

PAN MUST BE LOCATED UNDER

INDOOR COIL. FAILURE TO USE

THE DRAIN PAN CAN RESULT IN

PROPERTY DAMAGE.

!

CAUTION

WHEN USED IN COOLING

APPLICATIONS, EXCESSIVE

SWEATING MAY OCCUR WHEN

UNIT IS INSTALLED IN AN

UNCONDITIONED SPACE. THIS

CAN RESULT IN PROPERTY

DAMAGE.

!

CAUTION

CODES AND STANDARDS:

IT IS THE RESPONSIBILITY OF

THE INSTALLER TO FOLLOW ALL

NATIONAL CODES, STANDARDS

AND LOCAL ORDINANCES, IN

ADDITION TO INSTRUCTIONS

LAID OUT IN THIS MANUAL. THE

INSTALLATION MUST COMPLY

WITH REGULATIONS OF THE

LOCAL BUILDING, HEATING,

PLUMBING, AND OTHER CODES.

WHERE LOCAL CODES ARE NOT

APPLICABLE, THE INSTALLATION

MUST COMPLY WITH THE

NATIONAL CODES AND ANY AND

ALL AUTHORITIES HAVING

JURISDICTION.

!

NOTICE

!

WARNING

DO NOT OPERATE THE SYSTEM

WITHOUT FILTERS. A PORTION

OF THE DUST ENTRAINED IN THE

AIR MAY TEMPORARILY LODGE

IN THE DUCT RUNS AND AT THE

SUPPLY REGISTERS. THIS

RESIDUE COULD SOIL CEILINGS,

WALLS, DRAPES, CARPETS AND

OTHER ARTICLES IN THE HOUSE.

SOOT DAMAGE MAY OCCUR

WITH FILTERS IN PLACE, WHEN

CERTAIN TYPES OF CANDLES,

OIL LAMPS OR STANDING PILOTS

ARE BURNED.

Summary of Contents for RW1P

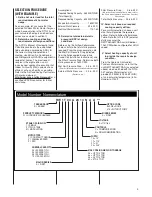

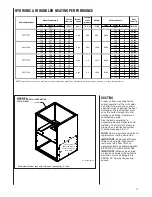

Page 29: ...29 FIGURE 21 ELECTRICAL WIRING DIAGRAM PSC MOTORS RW1P...

Page 32: ...32 FIGURE 24 ELECTRICAL WIRING DIAGRAM...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36 CM 0617...