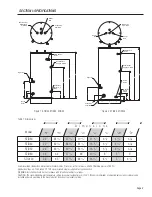

eleCTrICal ConneCTIons

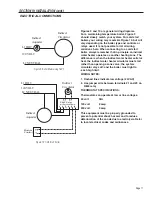

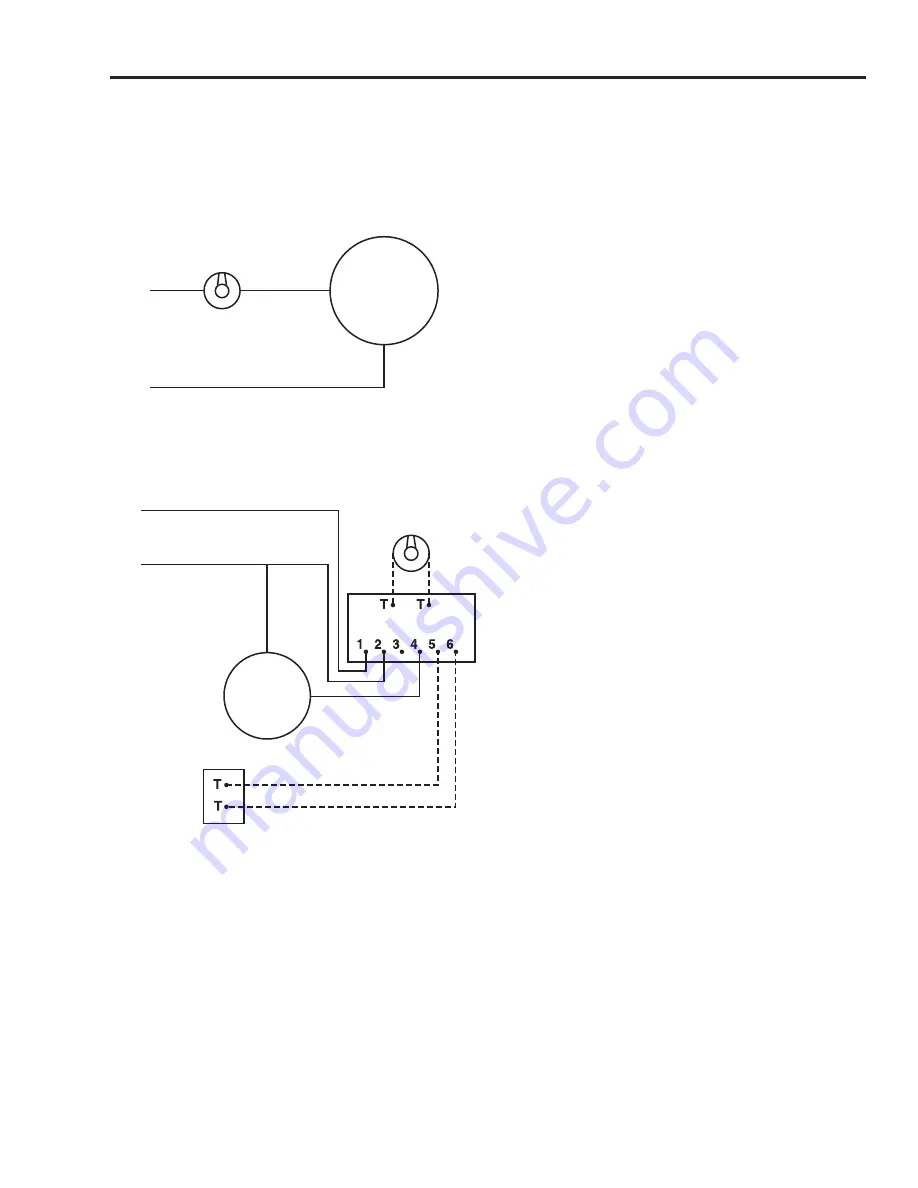

Figures 9 and 10 are general wiring diagrams.

For a maintaining temperature boiler, Figure 9

should closely match your system. For cold start

boilers your wiring may resemble Figure 10, but will

vary depending on the boiler type and controls or

relays used. It is not possible to list all wiring

variations here. When connecting to a cold start

boiler, always remember that in principle an indirect

water heater operates as another heating zone. The

difference is when the indirect water heater calls for

heat, the indirect water heater circulator must start

rather than opening a zone valve; the system

circulator stays off; and the boiler must light to

reach high limit.

WIRING NOTES:

1. Dashed lines indicate low voltage (24 VAC)

2. Use jumper wire between terminals #1 and #3 on

R845 relay

THERMOSTAT SPECIFICATIONS:

Thermostats can operate at low or line voltages.

24 volt

N/A

120 volt

8 amp

240 volt

5 amp

This equipment must be properly grounded to

prevent a potential shock hazard, and to reduce

deterioration of the anode due to electrolysis. Refer

to local electrical codes and ordinances.

Page 11

SECTION IV: INSTALLATION (cont .)

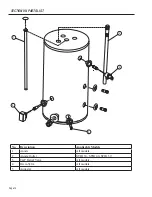

Figure 9: Boiler Maintaining 180°F

Figure 10: Cold Start Boiler

Figure 9: Boiler Maintaining 180°F

Indirect

Aquastat

Indirect

Circulator

L1 HOT

120 VOLT

L2 NEUTRAL

Figure 10: Cold Start Boiler

L1 HOT

120 VOLT

L2 NEUTRAL

Indirect

Circulator

Indirect

Aquastat

Burner

Control

R845 Relay

or Equivalent