TM012 Rheem Electric Water Heaters Service Instructions REV: B

Date of Issue: 03/06

This document is stored and maintained electronically by

Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

25

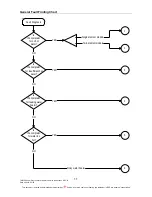

Fault Finding Chart 7

7

Is the

reading below 1

mega-ohm?

Electrical Insulation Test

Replace element

YES

Is the

reading below 1

mega-ohm?

Replace thermostat

Rewire fuse or reset circuit breaker

if necessary

Rewire fuse or reset circuit breaker

if necessary

YES

Check for pinched or damaged

wiring touching the heater chassis

NO

Disconnect the wires to the

element from the thermostat and

megger between each element

wire and earth

Disconnect remaining wires from

the thermostat and megger

between each thermostat terminal

and earth

NO

Electrical Insulation Testing

There are three basic test procedures that should be carried out when the operation and

function of a water heater’s electrical system is in doubt.

Personal Protective Equipment should be worn when conducting step 1 of

this procedure to reduce the risk of electric shock. Refer to Rheem safety

procedure on electrical testing.

Test 2 - To check insulation resistance of the water heater Neutral Circuit (reading

not to be below 1 mega-ohm).

1.

Isolate power to the water heater by removing fuse. Confirm with multi-meter

across Active and Neutral at the terminal block that voltage is not present.

2. Once satisfied, disconnect the active and neutral wires from the terminal block.

3. Connect megger leads to the neutral of the water heater wiring and earth.

4. Operate megger. A reading above 1 mega-ohm should be obtained.

5. If a reading below 1 mega-ohm is indicated, all component parts will need to be

individually tested to locate the fault. Refer to flow diagram 7 above.

Test 3 - To check insulation resistance of the water heater Active Circuit (reading

not to be below 1 mega-ohm).

6. Connect megger leads to the active of the water heater wiring and earth.

7. Operate megger. A reading above 1 mega-ohm should be obtained.

8. If a reading below 1 mega-ohm is indicated, all component parts will need to be

individually tested to locate the fault. Refer to flow diagram 7 above.

Test 4 - To check “Continuity” of water heater electrical circuit.

9. Set megger to resistance scale or multimeter to x1 resistance scale.

10. If a reading greater than 50 ohms is indicated, all electrical component parts will need

to be individually tested to locate the fault. Refer to test 8, page 15 for indicative

resistances.

11. Reconnect the active conductor to the ‘A’ terminal and neutral conductor to ‘N’ terminal

at heater terminal block.

12. Replace fuse.

Note:

If continuing with flow chart 1.1 or 2.1of diagnostic

procedure do not replace fuse.