25

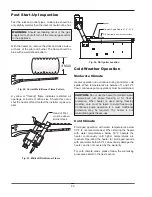

Pilot Removal & Cleaning

(Millivolt)

1. Disconnect pilot tubing and wires from gas valve.

2. Remove pilot assembly from burner tray.

3. Remove pilot from bracket.

4. Remove pilot orifice and air opening (Honeywell

MV unit only), and clean with wire or small brush.

5. Reverse above procedure to reinstall.

Heat Exchanger Removal

1. Shut water, gas and electricity off, close valves

and relieve pressure, then remove relief valve.

Remove side inspection panels.

2. Remove top jacket holding screws. Remove the

jacket top.

3. Remove the four (4) screws holding down the flue

collector. Remove the flue collector.

4. Remove upper in/out access panel.

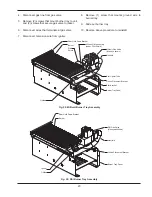

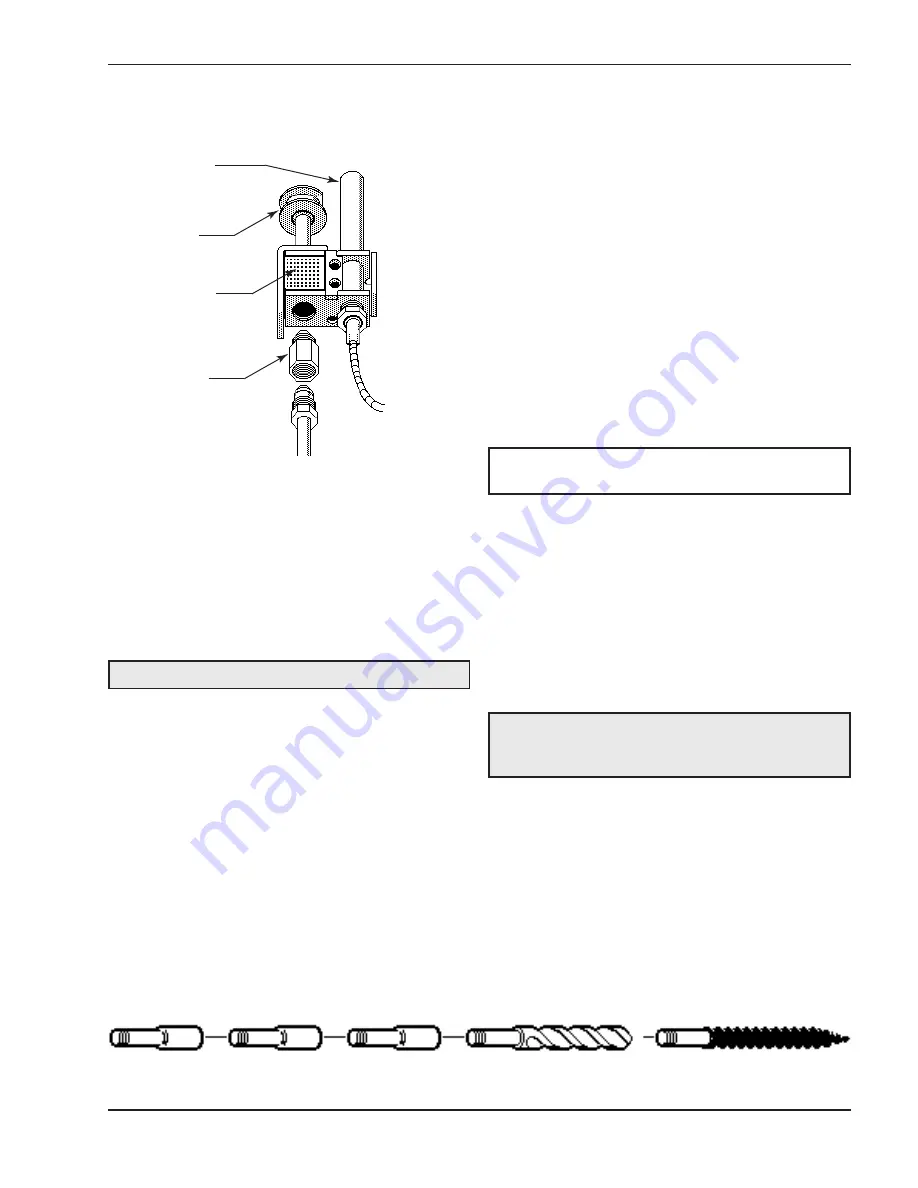

Pilot

Thermopile

Air Opening

Orifice

Fig. 33: Honeywell Millivolt Pilot

5. Disconnect all electrical wiring from in/out header.

6. Remove temperature sensor from in/out header.

7. Disconnect flange nuts on In/Out header.

8. Set aside heat exchanger side baffles.

9. Lift heat exchanger straight up using caution not to

damage refractory.

10. Reverse above procedure to reinstall.

Tube Cleaning Procedure

Establish a regular inspection schedule, the frequency

depending on the local water conditions and the sever-

ity of service. Do not let the tubes clog up solidly.

Clean out deposits over 1/16" in thickness.

Use the Tube Cleaning Kit #052871F to ream the

tubes as necessary. After reaming, mount the wire

brush in place of the auger and clean out debris

remaining in the tubes.

Another method is to remove the heat exchanger,

ream tubes and immerse heat exchanger in non-inhib-

ited de-scale solvent for severe scale build-up.

De-sooting Procedure

Soot will clog areas between fins and cause eventual

tube failure. Any sign of soot at the base of the burn-

ers or around the outer jacket indicates a need for

cleaning.

1. Remove top and flue collector from cabinet.

2. Remove "V" baffles from heat exchanger, includ-

ing side baffles.

3. Remove burner tray.

CAUTION:

Do not enlarge hole in pilot orifice.

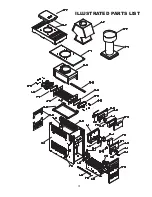

Extension Pieces (2)

Auger with Carbide Tip

Wire Brush

Fig. 34: Tube Cleaning Kit

NOTE:

Please remove heat exchanger from heater

prior to reaming or removing debris.

CAUTION:

Soot may be combustible. Wet sooted

surfaces completely prior to cleaning. Do not use

steel wire brush.