15

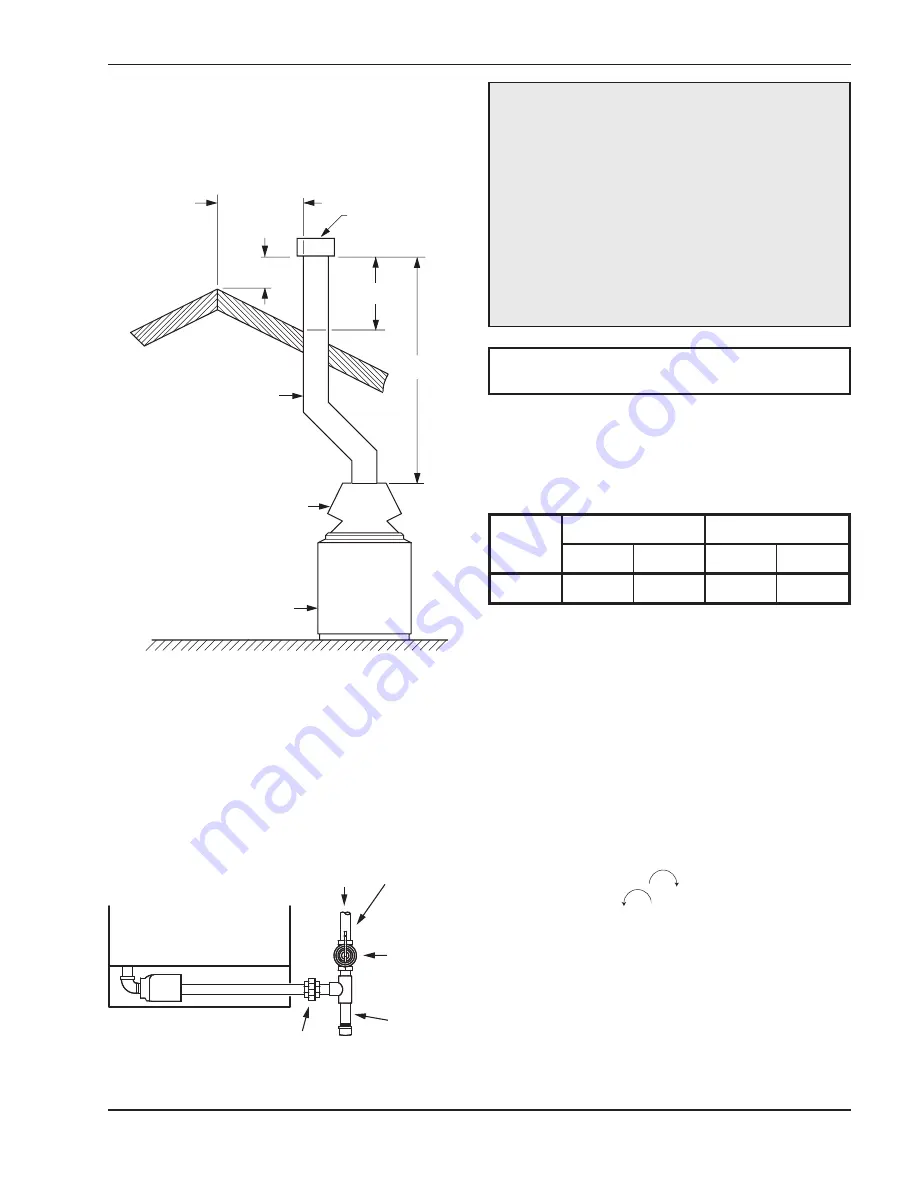

Type "B" double wall or equivalent vent pipe is recom-

mended. However single-wall metal vent pipe may be

used as specified in the latest edition of the National

Flue Gas Code ANSI Z223.1 (Canada-CAN/CGA B-

149).

Gas Supply Connections

Gas piping must have a sediment trap ahead of the

heater gas controls, and a manual shut-off valve locat-

ed outside the heater jacket. All gas piping should be

tested after installation in accordance with local codes.

5' MIN

2' MIN

10' OR LESS

2' MIN

VENT CAP

VENT PIPE

DRAFT HOOD

HEATER

Fig. 9: Venting Clearances

A minimum of 7" WC and a maximum of 10.5" WC

upstream pressure under load, and no load conditions

must be provided for natural gas, or a minimum of 12"

WC and a maximum of 13" WC for propane.

Gas Pressure Regulator

SUPPLIED

BY OTHERS

GA

S

F

LO

W

U

N

IO

N

SEDI

M

E

N

T

TR

A

P

M

A

N

U

A

L

SHUT

-

O

FF

V

A

L

V

E

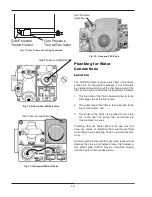

Fig. 10: Sediment Trap

CAUTION:

The heater and its manual shut-off

valve must be disconnected from the gas supply

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.45 kPa). Dissipate

test pressure in the gas supply line before

reconnecting the heater and its manual shut-off

valve to gas supply line. FAILURE TO FOLLOW

THIS PROCEDURE MAY DAMAGE THE GAS

VALVE. OVER PRESSURED GAS VALVES ARE

NOT COVERED BY WARRANTY. The heater and its

gas connections shall be leak tested before placing

the appliance in operation. Use soapy water for leak

test. Do NOT use open flame.

NOTE:

Do not use teflon tape on gas line pipe

thread. A flexible sealant is recommended.

Model

1/2”

3/4”

N

P

N

P

055B

90

200

200

250

Natural Gas, 1000 BTU/FT

3

.60 specific gravity @ 0.5” WC pressure

drop

Propane Gas, 2500 BTU/FT

3

1.53 specific gravity @ 0.5” WC pres-

sure drop

Table D: Maximum Equivalent Pipe Length

The gas pressure regulator is preset and sealed at 4"

WC for natural gas, and 11" WC for propane. Between

the gas valve and the burners is a 1/8" pipe plug. The

pressure at this point, taken with a manometer, should be

about 3.7" WC natural gas and 10.5" WC propane.

If

an adjustment is needed, remove seal and turn adjust-

ment screw clockwise

to increase pressure or

counter-clockwise

to decrease pressure.