27

These instructions are primarily intended for use by qualified personnel specifically trained and experienced in the

installation of this type of heating equipment and related system components. Installation and service personnel may

be required by some states to be licensed. Persons not qualified shall not attempt to install this equipment nor attempt

repairs according to these instructions.

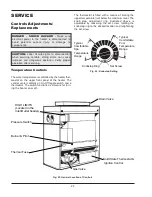

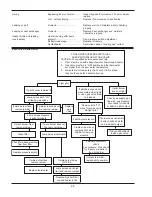

MECHANICAL

PROBLEM

CAUSE

SOLUTION

Harmonics, or whining noise

U.G.inoperative................................. Check movement by putting in hot water (110°F

or higher). If no movement, replace.

*Debris or restriction in system....... Locate the restriction and remove. Flush system

and clean.

*Debris in gas line.............................. Remove debris or blow out gas line.

Lowflow.............................................. Scale forming in heat exchanger - clean heat

exchanger and check pool pH and total alkalinity.

Heater going on and off

Dirty filter............................................. Backwash filter.

continuously

Low water level in pool.................... Raise water level.

External bypass setting out of

adjustment......................................... Adjust bypass.

*Pressure switch out of

adjustment......................................... Adjust pressure switch.

Liming or scale forming on

Pool water chemical imbalance.... See Water Chemistry on page 2.

heat exchanger

g

n

it

o

o

S

High flow rates.................................. Reduce by adding manual bypass valve and

adjust by putting thermometer in header (1/4"

NPT) drain opening. Set bypass so thermom-

eter reads between 105° and 110°F.

U.G.inoperative................................. Check movement by putting in hot water (110°F

or higher). If no movement, replace.

*Airstarvation....................................... Refer to installation instructions.

*Improper venting............................... Follow recommended installation instructions.

*Insects or debris clogging

burner intake ports........................... Clean burners.

.

e

r

u

s

s

e

r

p

s

a

g

t

s

u

j

d

A

..

..

..

..

..

..

..

..

..

..

..

..

..

..

e

r

u

s

s

e

r

p

s

a

g

w

o

L

e

g

a

t

u

o

t

o

li

P

Restricted pilot.................................. Clean pilot.

Weak pilot generator........................ Replace pilot.

Yellow lazy flame

Low gas pressure............................ Adjust gas pressure.

*Insects or debris clogging

burner intake ports........................... Clean burners.

Outer jacket very hot

*Broken refractory caused by

(paint blistered)

shipping damage or improper

combustion........................................ Replace refractory panels.

Excessive sooting of heat

exchanger........................................... Determine cause of sooting & correct.

Takes long time to heat

Undersized heater............................. Check heat rise per hour with the following

pool or spa

formula:

Heat rise (°/hr.)= Heater Output

Pool gallonage x 8.33

Filter not running long enough....... Reset time clock.

Dirtyfilter............................................. Clean filter.

Gas line or meter undersized......... Refer to installation instructions.

(* Usually occurs on initial start-up.)

TROUBLESHOOTING