Start-up and Control

The glue applicator must only be used/applied for its

intended purpose. Please read the chapter „General

Safety Instructions“. If it is not used as intended, this

may cause bodily injuries or equipment damages.

Disregard of the safety instructions for the use of the

applicator may lead to serious burns.

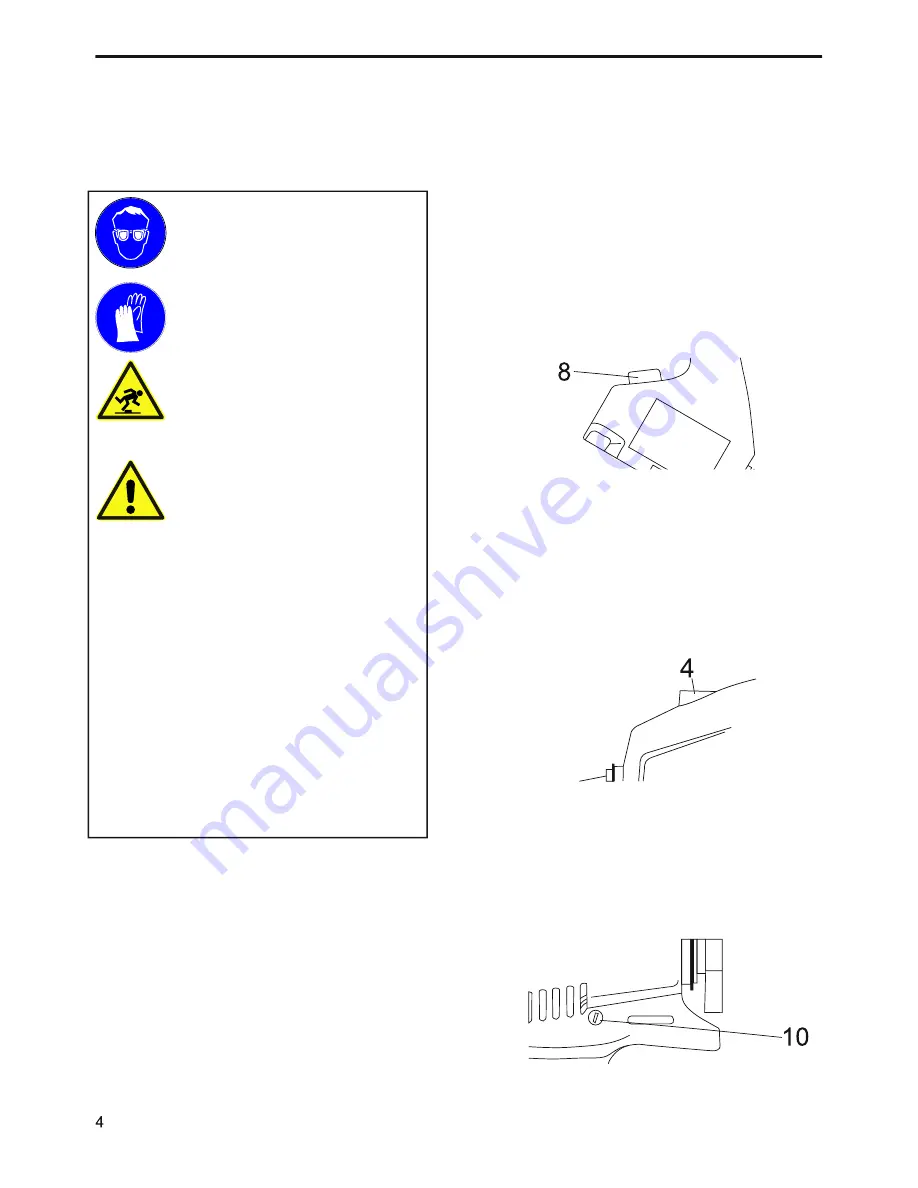

Switch Applicator on/off

An illuminated on/off-switch indicates that the applicator

is switched on. Press the switch in order to turn the

applicator on or off.

Minor leaking while the applicator is warming up is due

to the hot-melt expanding in the nozzle and heating

chamber.

Adjusting the trigger

The adjustment of the trigger has influence on the lever

stroke and on how much glue can be dispensed at once.

A screwdriver can be used to turn the adjustable screw

on the left side of the applicators’ casing. The longer the

lever stroke, the more glue can be dispensed at once

and vice versa.

Avoid accidents by stumbling – Lay all

cables, hoses and conducts so that they

will not cause any risk of stumbling. For

this, install cable ducts and bridges.

Wear protective gloves and safety

goggles whenever you work with the

applicator.

Never direct the glue jet towards people!

Never lay the hot-melt applicator on its

side.

Do not hold the nozzle top upward for too

long.

Do not carry out overhead work.

Do not start working, before fitting a

nozzle first.

Only replace nozzle when applicator is

warm.

Only open the lid when the applicator has

warmed up.

Do not overcharge the applicator; only fill

it up to 1,5 cm (~0.6 inch) under the rim.

Stop using the equipment, if the casing is

damaged due to shock, breakage or

heavy wear.

The MS 200 glue applicator is factory-set to 200 °C. The

temperature is continuously adjustable at the upper side

of the applicator, turning the adjusting screw with a

screw driver. The right-end stop is the maximum

temperature of 200 °C. In order to lower the working

temperature, turn the adjusting screw counter clockwise.

Adjust Temperature