Cleaning and Maintenance

Start-up and Control

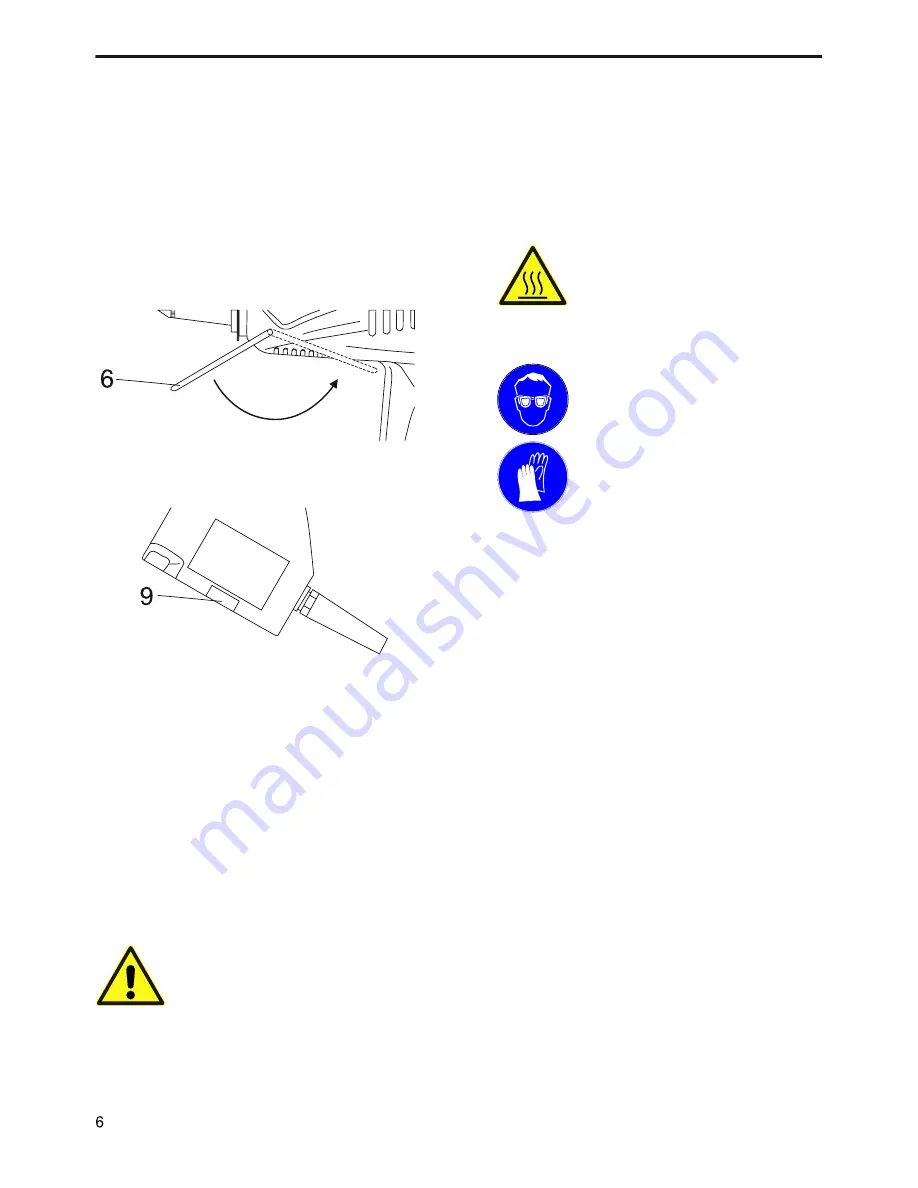

Picking up/put down the Applicator

The MS 200 has a wire stand which is used to put down

the applicator. Reka recommends folding in the wire

stand when working with the applicator.

Never fill soiled glue into the melting tank. If you observe all advices given in the operating manual, the glue applicator does,

normally, not need cleaning. The non-reactive glue contained in the applicator will remelt and can be used for gluing again.

The working temperature of the respective glue may be taken from the technical datasheet which can be procured from the

producer of the glue. This temperature must not be exceeded, otherwise the glue may coke in the glue applicator. Hot-melts on

a polyamide basis are particularly sensitive. If the glue has coked, the applicator with should be cleaned with REKA cleaning

liquid (article no. 3519).

Never clean the applicator with solvent, benzine, benzene, toluene, acetone, turpentine, etc. risk of explosion!

If the applicator is used very often, we recommend having it maintained regularly. For this, fix a date with our service department.

Further more, the MS 200 can be put down on magnetic

surfaces by using the magnetic foot. In this case the

wire stand is not needed and can stay folded in.

Replacement of Nozzles

Warning: risk of burns! When your skin got

into contact with hot glue, cool it with cold

water immediately. Do not try to remove

the hot-melt from the skin first. If

necessary, consult a doctor. When hot

adhesive got into your eyes, immediately

cool them under running water for about

15 minutes. Consult your doctor at once!

For your own safety: wear protective

gloves and safety goggles when you

replace nozzles.

Always unplug the applicator before

replacing a nozzle!

Only replace nozzles when the glue applicator is warm

(instrument temperature 60 – 80 °C ) and empty.

Replacing a nozzle when the applicator is cold may

damage the equipment. Replacing the nozzle when the

applicator is too hot, causes liquid glue to flow out. The

melting range as well as the melting point of the used

glue may be taken from the technical datasheet of the

respective glue.