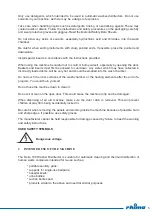

5.2

Values of the cycles

Recommended phase values of the cycles.

Time

, s

e

c

[ t

]

Temperatu

re

,

0

C

[ T

]

Detergent

volu

me

, m

l

[Q

]

NO

T

E

!

Cold water flush

This is always the first phase

Warm water flush

Circulation wash

60-1200

0-99

Hot water rinse

15-300

Must be before disinfection

Disinfection

1-300

75-95

Wait

I

t’s possible to program a waiting time at the end of the cycle 1

-20 min

- all cycles will start automatically with the cold water flush (container emptying phase)

- warm water flush use both cold and hot water, recommended after cold water flush

- circulation wash includes time and detergent volume parameters

- circulation hot water rinse must be before disinfection, only the rinsing time can be set

- disinfection parameters are time and temperature

- waiting time after the cycle can be used for cooling down the instruments

Note!

The set disinfection time starts when the set temperature has been reached.

Do not use raw water rinsing or washing after disinfection phase.

Note ! If the cycle does not include disinfection phase, user will be warned by starting the cycle.

Read more from chapter 10.0 Programming (Maintenance manual).

5.3

Process chemicals

Deko 190 can be equipped with one adjustable dosage pump for detergent.

As an option the machine can be equipped with a descaling liquid pump.

Please note that the nature of the item to be processed can require additional actions such as

dismantling for separate processing, the pre-cleaning of difficult surfaces (inaccessible sites) by a

manual process etc. prior to the item being processed by the machine. Such pre-cleaning can be

necessary to reduce the initial bioburden and/or contamination. Please consult the manufacturer

of the medical device for processing instructions and note that the cleaning agents and

disinfectants used by manual processing must be carefully flushed away with water before the

items are loaded into the washer-disinfector. Failure to do so, may cause excessive foaming

and/or pressure drop in the water recirculation system decreasing the cleaning efficacy and

extending the cycle time.

Depending on the materials of the medical device being processed a variety of different cleaning

agents may be used. Generally, detergents shall be liquid, non-foaming, non-abrasive, free

rinsing and biodegradable and have the authorities' approvals for their intended use, as required.

11