Operative Instructions

28

observance of what is reported in this manual.

a

WARNING! The bedpan washer maintenance

operations must be carried out with the

machine completely switched off (turn off

the main circuit breaker).

a

WARNING!

To

prevent

bacterial

proliferation, the machine is equipped

with a Self Disinfection System (S.D.S.)

that automatically perform a disinfection

program 24 hours after the last cycle.

The routine maintenance operations and the frequency

of maintenance are described in the Maintenance

Logbook.

The Maintenance Logbook is an integral part of this

manual. If the Maintenance Logbook is missing, contact

your dealer or distributor.

a

WARNING

! it is the user's obligation to

fill in and keep updated the Maintenance

Logbook. The incorrect or incomplete

compilation of the Maintenance Logbook

will void the warranty.

9.1.1 Periodic maintenance request

After a certain time or a certain number of operating

hours, the display shows «MAINTENANCE», if enable.

This signal has no influence on the machine operation,

contact the customer service or the dedicated technical

assistance for periodic maintenance.

a

WARNING! Periodic maintenance is carried

out by the technician under guarantee only if

the uilizer has correctly and regularly carried

out all ordinary maintenance operations and

if the uilizer has filled out and kept up-to-

date the Maintenance Logbook.

9.1.2 Personal Protective Equipment (PPE)

The operator engaged in this type of intervention must

wear PPE and must be sure that no other unauthorised

person is present in the operating area of the machine.

Before maintenance, start a program to wash the

washing chamber.

9.1.3 Cleaning products

Clean the outside of the machine with products

suitable for stainless steel, glass and plastic materials.

b

HAZARD!

Products

unsuitable

for

cleaning stainless steel, glass and plastic

materials may irreparably damage non-

interchangeable parts of the appliance and

render the machine unusable.

If a suitable cleaning liquid is not available, a mixture of

water (75%) and alcohol (25%) may be used. Cleaning

should be carried out with a smooth (non-scratchy)

cloth moistened with the appropriate liquid.

a

WARNING! Do not spray the machine or near

it with water jets, or with pressure devices.

c

HAZARD! DO NOT SOAK THE CLOTH

to prevent excess liquid from entering

electrically hazardous areas for the operator.

The keypad and display should be cleaned with a

mixture of water and alcohol or with mild detergents.

The washing chamber is automatically cleaned. In case

of need, for an extra cleaning of the washing chamber,

run a rinse cycle without introducing instruments.

a

WARNING! Do not use steel wool, steel

brushes, bleach (bleach cause the oxidation

of the stainless steel surface and consequent

change of color) or any cleaning agent

containing bleach or anything abrasive to

cleaning the device. Doing so will damage

the device!

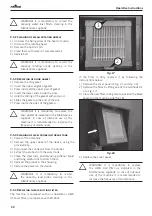

9.2 Weekly checks

9.2.1 Anti-scale

Periodically check the level of anti-scale product

contained in the drum located in the compartment

below the wash basin. A label near the cap indicates

the type of liquid contained in the drum. A message

on the display warns when the liquid is getting low and

when it is totally finished.

Moreover, the machine has a volumetric meter, which

controls the quantity of passing liquid. This is another

control system: the meter stops the working cycle

and the display will show an alarm every time that

the dispenser pump doesn’t work well or the liquid is

totally finished.

9.2.2 Detergent

Periodically check the level of detergent liquid

contained in the drum (when present) located in the

compartment below the wash basin. A label near the

Summary of Contents for DVS

Page 40: ...Operative Instructions 40 Notes ...

Page 41: ...Operative Instructions 41 Notes ...