Operative Instructions

29

cap indicates the type of liquid contained in the drum.

A message on the display warns when the liquid is

getting low and when it is totally finished.

Moreover, the machine has a volumetric meter, which

controls the quantity of passing liquid. This is another

control system: the meter stops the working cycle

and the display will show an alarm every time that

the dispenser pump doesn’t work well or the liquid is

totally finished.

9.3 What to do if the machine hasn’t been

used for a long time

9.3.1 Storage tank

If the machine hasn’t been used for a long time without

electrical supply, it is good to empty manually the

storage tank using the drainage valve under it: in this

way the proliferating of bacteria is avoid.

In every 15883 machine this operation is automatic

every time the machine doesn’t work for a long time,

even without electrical supply.

9.3.2 Steam generator

If the machine hasn’t been used for a long time without

electrical supply, it is good to empty manually the

steam generator using the drainage cap under it: in this

way the proliferating of bacteria is avoid.

9.4 Routine maintenance

Routine maintenance operations are performed by

the user and includes all those jobs needed to keep

the machine clean and functioning. It is mandatory to

perform these operations regularly or when necessary

and the user is responsible for verifying their regularity.

For routine maintenance operations refer to the

Maintenance Logbook provided in the machine's pack.

a

WARNING

! it is the user's obligation to

fill in the Maintenance Logbook correctly

and regularly. The incorrect or incomplete

compilation of the Maintenance Logbook

will void the warranty.

9.4.1 Cleaning the human waste containers hook/

support and machine's surfaces

Sometimes it may be necessary to remove the

human waste containers hook/support to replace it

or to perform routine, extraordinary maintenance or

cleaning. To remove the support just pull it towards

yourself until the support connections are released

from their two anchor plates. To reinsert the support

perform this operation in reverse order.

For machine's surfaces cleaning follow the instructions

in 9.1.3.

a

WARNING! Whenever a new support is

inserted make sure it is correctly fastened to

its connections.

9.5 Special maintenance

Special maintenance operations are not foreseen by

the user but must be performed exclusively by the

technical assistance or by an authorised and qualified

service personnel that must refers to the Service

Manual.

How to carry out special maintenance operations and

the frequency of maintenance are described in the

Service Manual.

Contact the manufacturer service for special

maintenance.

a

WARNING! Special maintenance is carried

out by the technician under guarantee only if

the utilizer has correctly and regularly carried

out all ordinary maintenance operations and

if the uilizer has filled out and kept up-to-

date the Maintenance Logbook.

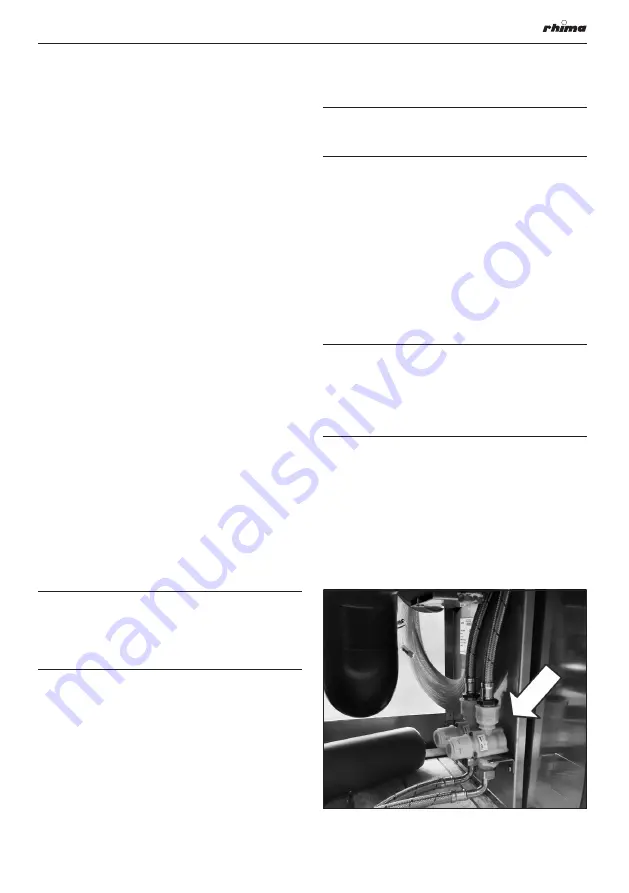

9.5.1 Cleaning the water inlet filters

Proceed as follows to clean the water inlet filters.

1) Look at the back of the machine at the bottom

(Fig. 16).

2) Unscrew the cap.

3) Remove the filter.

4) Clean the filter.

5) At the end of the cleaning operations, refit the

filters in succession.

Fig. 16

Summary of Contents for DVS

Page 40: ...Operative Instructions 40 Notes ...

Page 41: ...Operative Instructions 41 Notes ...