Operative Instructions

5

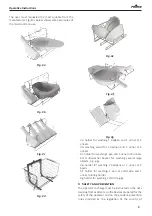

This model of bedpan washer can be installed

(according to the choice made during configuration):

- Stand alone

- Wall-hung

- Built-in model

- Undercounter

a

WARNING! Failure to comply with the

instructions

in

manual,

operational

negligence, incorrect use of the bedpan

washer and execution of unauthorised

changes, both on the machine and on the

programs, are the cause of cancellation by

the manufacturer of the warranty granted.

For the installation schemes see the Technical

Specifications (see pg. 2).

Ö

IMPORTANT

NOTE!

The

Technical

Specifications (see pg. 2) must be considered

as an integral part of this user Manual.

2.1 Field of application

This machine, intended for washing and disinfecting,

is considered a class IIa medical device (as defined by

Directive 93/42/EEC class IIa). Follow the instructions

of the instrument manufacturers (according to EN

ISO 17664), as well as the national laws and directives

for the automatic treatment of medical devices. The

personnel in charge using the machine daily must

be aware of its main features, and must also receive

adequate and continuous training.

2.1.1 Intended use

The bedpan washer is designed for the needs of

washing and disinfecting badpans, urine bottles,

commodes, urology containers, kidney-shaped basins,

drainage bottles and other clinical containers used in

hospital wards.

2.1.2 Intended users

Specialized personnel capable of working in a CSSD,

Hospital’s disinfection area and nursine homes.

2.1.3 Intended use of environment

The machine is intended to be used only for internal

uses. The machine is designed to be operational up

to a maximum altitude of 2000 metres (6562 ft), at a

temperature between 5 and 40°C (41 and 104°F) and

used in an environment with a maximum humidity of

80% for temperatures up to 31°C (88°F), decreasing

linearly to 50% at 40°C (104°F).

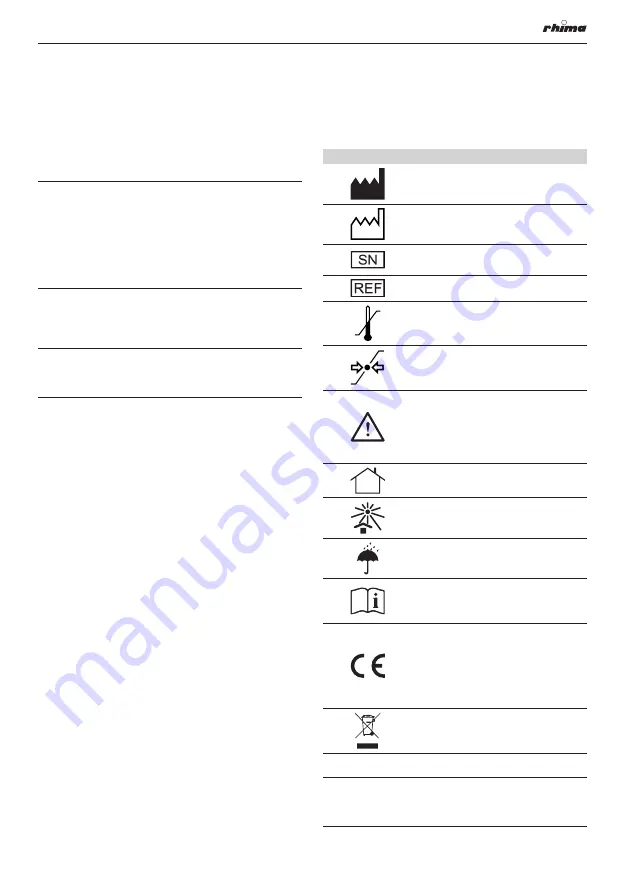

2.2 Label specification

Each bedpan washer is equipped with an identification

label (for the position see 8, Fig. 2). The following table

shows the symbols used on the identification label:

Symbol

Description

Manufacturer of the device.

Date of manufacture of the device.

Device serial number from the

manufacturer.

Model name of the device.

Indicates the permitted temperatu-

re range (min./max.) of the water

supply (steam where present).

Flow pressure on the water inlet

(steam where present) connected

from min. to max.

The user manual includes important

safety information. Failure to comply

with these instructions can result in

injury and material damage. Please

read carefully the user manual.

For indoor use only.

Keep away from sunlight.

Keep dry.

Please read this user manual

carefully before commissioning the

device.

In affixing this CE mark, the

manufacturer declares that this

product fulfils the basic requiremen-

ts of the machinery directive.

The number below the mark identify

the notification body.

For the disposal of the machine

please refer to chapter "Equipment

Disposal".

Ö

IMPORTANT NOTE! Do not cover the labels

placed on the machine for any reason and

replace them immediately if damaged.

xxxx

Summary of Contents for DVS

Page 40: ...Operative Instructions 40 Notes ...

Page 41: ...Operative Instructions 41 Notes ...