Assembly Instructions

14X30X12 Round Utility

Using (4) 3¼” Carriage Bolts (CBN-3005-3) with nuts

and washers, connect the cross rails between the end

arch and the first interior arch assemblies. Connect the

(2) Wind Braces (CW-2800) diagonally across the end

and interior arch as shown in the frame illustration. The

addition of the wind braces on both sides will allow the

assembly to be self-supporting.

V2.3

Please Do NOT Return Assembly to Dealer or Store. For All Assembly Questions or Shortages Please Call MDM Products directly

Customer Service 800-447-7079 or 203-877-7070

4

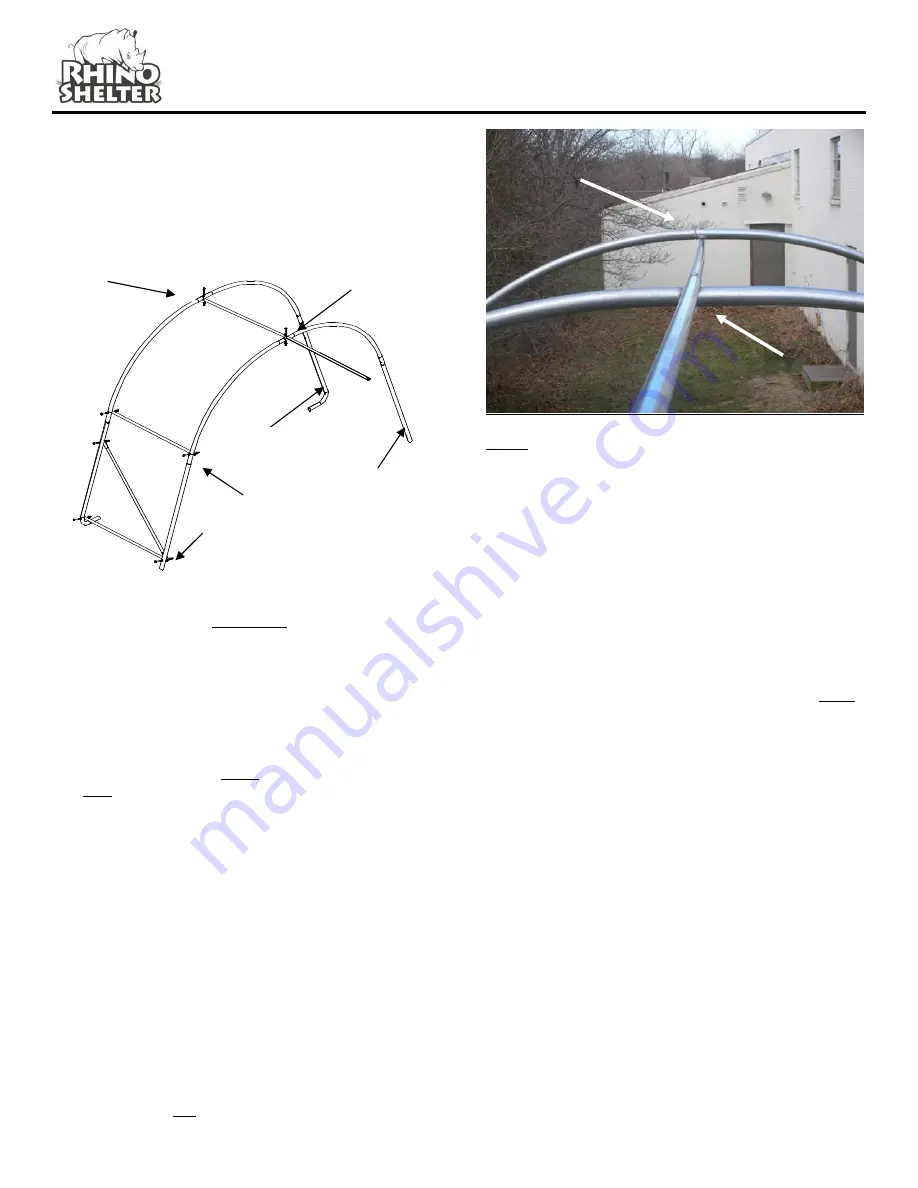

Step 4

. Begin the Top Ridge Rail by placing a Plain End

Cross Rail (ECR-5031) underneath the End Arch Tube.

Secure the Cross Rail loosely with a 3¼” Carriage Bolt

(CBN-3005-3) with washer and nut facing the interior of

the unit. Place the other end of the ridge pole over the

first interior arch, and secure loosely with a 3¼” carriage

bolt and nut.

Step 6.

Add remaining 4 middle arches and rear end

arch in the same fashion. Note that the Plain end of Top

Cross Rail should fasten under the End Top Crest Arch

and over the interior Top Ridge arches.

Under End

Arch

Top Ridge Over

Interior Arches

Top Ridge

Under End

Arches

Over

Interior Arch

NOTE: Do not completely tighten bolts that connect the

Cross Rails to the End Arches. They must be removed

for proper for End Panel Zippered Door installation

For each arch that is added, add a side cross rail and

the top ridge rail by inserting a swedged end cross rail

(SCR-5030) into the prior pole end. By adding cross

rails at base, side, and top ridge, the arches will

integrate into a strong frame assembly. For the other

End Arch Assembly, be certain to install the remaining

two (2) Wind Braces (CW-2800) for stability.

Step 7

. Move the frame assembly into its final

installation location. This should be done with at least

one person lifting each arch upright and corner to avoid

bending or stressing any frame members. Frame

must

then be squared up in position. Use a straight line string

to align all frame members on the first side into position.

Then measure and adjust each arch end to the proper

base width of 14’ to align the other side. Finally

measure diagonally from inside corner to inside corner of

frame. Both diagonal measurements should match.

Measure at each end across base of arches. Do not

expand arch width beyond 14’ wide. This will severely

reduce strength of arch assembly and cause fabric

misfit. Adjust frame and support as necessary to bring

frame into square.

Failure to square frame of unit will

result in poor main cover fit and reduced strength

and rigidity

.

End Arch

Assembly

Side Ridge &

Base Ridge Poles

Inside unit

Interior

Arch

Assembly