OPERATION

2407TL 01/11

Operation Section 4-8

© 2011 Alamo Group Inc.

OPERA

T

ION

4. Getting On and Off the Tractor

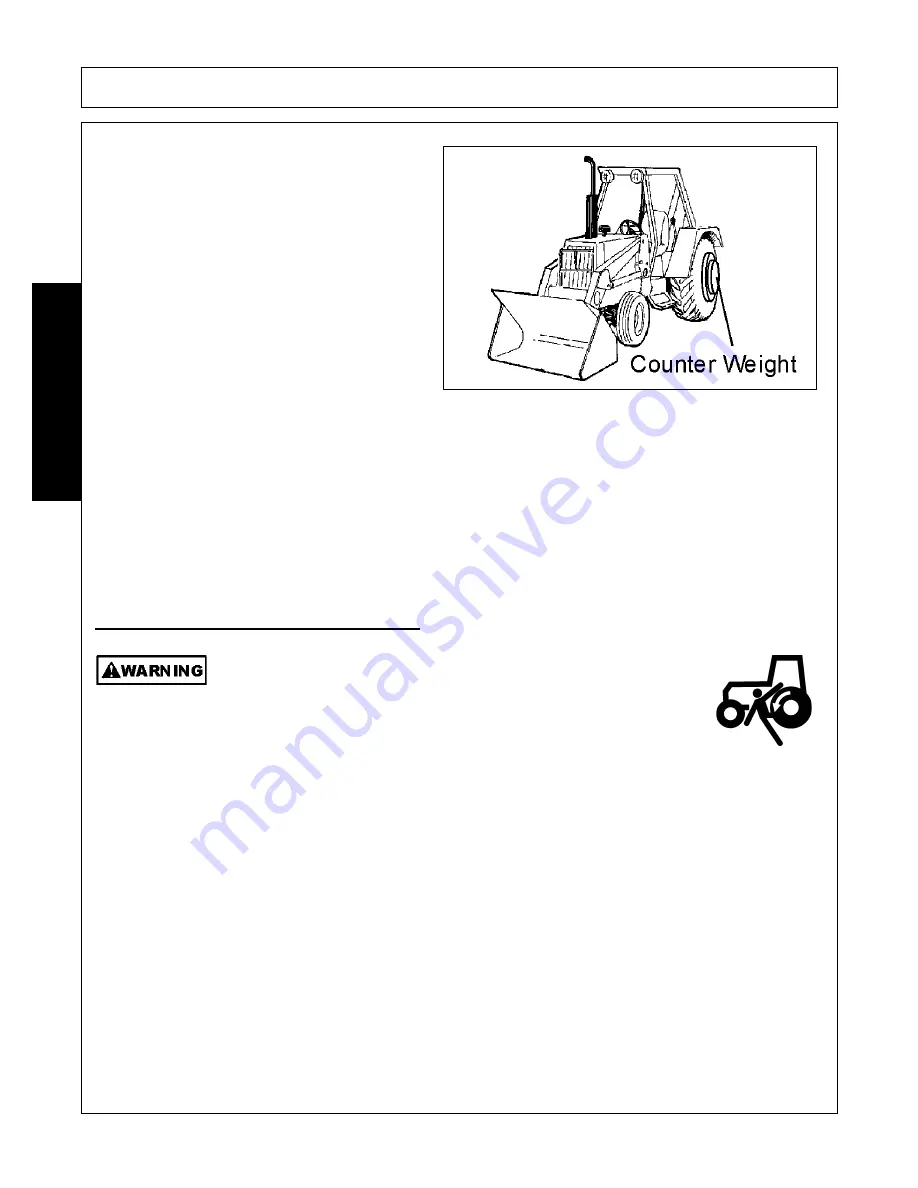

To ensure tractor stability when operating add

wheel ballast or rear weights to rear tractor tires.

For better stability, use tractor with wide front axle

rather than tricycle front wheels. Move wheels to

the tractor manufacturer’s widest recommended

settings to increase stability. If 3-Point hitch

counterweights are used, they should be carried

as low as possible at all times to maximize stability.

Effective counterbalance weight at rear axle of

mounted rear equipment is determined by

multiplying actual weight of equipment by 1.50.

EXAMPLE:

Equipment weighing 800 pounds,

attached to tractor, multiplied by 1.50, equals 1200

pounds of effective counterbalance weight at rear

axle.

A tractor that does not meet this criteria is

DANGEROUS and should not be operated as

upset of the unit can occur resulting in possible

serious injury and property damage.

OPS-L-

0001_A

Do not mount or dismount the Tractor while the tractor is moving. Mount

the Tractor only when the Tractor and all moving parts are

completelystopped.

(SG-12)

Before getting onto the tractor, the operator must read and completely understand the implement and tractor

operator manuals. If any part of either manual is not completely understood, consult an authorized dealer for

a complete explanation.

OPS-L- 0022

Summary of Contents for 2407TL

Page 5: ...Safety Section 1 1 SAFETY SECTION...

Page 27: ...Introduction Section 2 1 INTRODUCTION SECTION...

Page 32: ......

Page 33: ...Assembly Section 3 1 ASSEMBLY AND CONNECTING THE LOADER SECTION...

Page 40: ......

Page 41: ...Operation Section 4 1 OPERATION SECTION...

Page 84: ......

Page 85: ...Maintenance Section 5 1 MAINTENANCE SECTION...

Page 95: ...MAINTENANCE 2407TL 01 11 Maintenance Section 5 11 2011 Alamo Group Inc MAINTENANCE...

Page 96: ...MAINTENANCE 2407TL 01 11 Maintenance Section 5 12 2011 Alamo Group Inc MAINTENANCE...

Page 97: ......

Page 100: ...2407TL SOM 01 11 P N F 4003C Printed U S A 2407TL LOADER...