MAINTENANCE

2409TL 01/11

Maintenance Section 5-4

© 2011 Alamo Group Inc.

MAINTENANCE

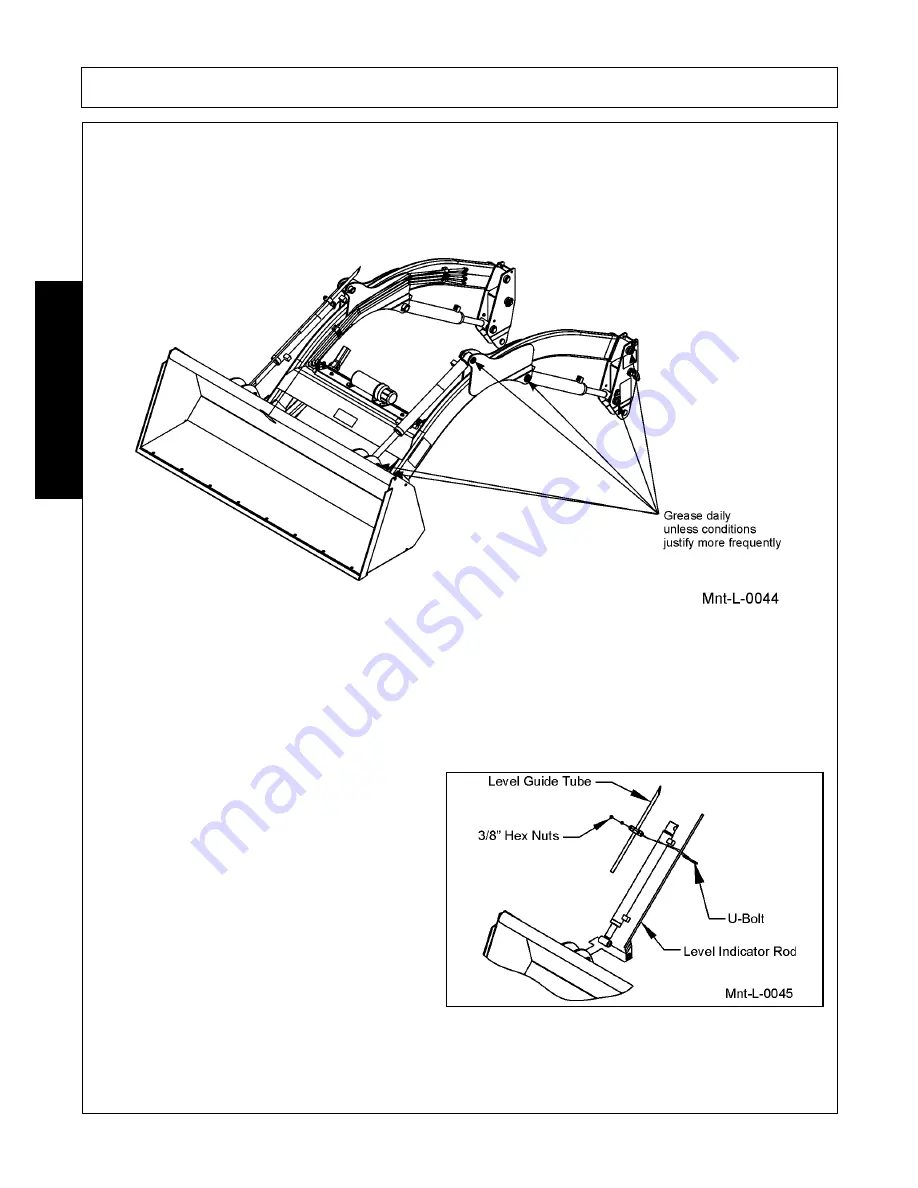

Lubrication Schedule

Before operating your Loader, take the time to inspect and repair any damage to the machine or tractor. Only a

minimum of time and effort is required to regularly maintain this machine to provide long life and trouble free

operation.

Lubricate all grease fittings: one at each end of lift boom arms and one at rod and base ends of each lift and

bucket cylinders.

NOTE:

Fully retract bucket to a comfortable height to grease bucket/loader boom joint. Do not reach or stand

under a raised loader or attachment without proper support.

Adjusting Bucket Level Indicator

With various tractor tire options or attachments, it

may be necessary to adjust bucket level indicator

tube up or down on bucket cylinder tube. Tractor

must be on level surface with attachment flat on

surface. Loosen u-bolt hex nuts and adjust level

guide tube along bucket cylinder until end of guide

tube is flush wtih end of rod. Tighten u-bolt hex

nuts.

Summary of Contents for 2409TL

Page 5: ...Safety Section 1 1 SAFETY SECTION...

Page 29: ...Introduction Section 2 1 INTRODUCTION SECTION...

Page 34: ......

Page 35: ...Assembly Section 3 1 ASSEMBLY AND CONNECTING THE LOADER SECTION...

Page 47: ...Operation Section 4 1 OPERATION SECTION...

Page 91: ...Maintenance Section 5 1 MAINTENANCE SECTION...

Page 100: ...MAINTENANCE 2409TL 01 11 Maintenance Section 5 10 2011 Alamo Group Inc MAINTENANCE...

Page 101: ...MAINTENANCE 2409TL 01 11 Maintenance Section 5 11 2011 Alamo Group Inc MAINTENANCE...

Page 104: ...2409TL SOM 01 11 P N F 4203C Printed U S A 2409TL LOADER...