ASSEMBLY

TW120 01/11

Assembly Section 3-8

© 2011 Alamo Group Inc.

ASSEMBL

Y

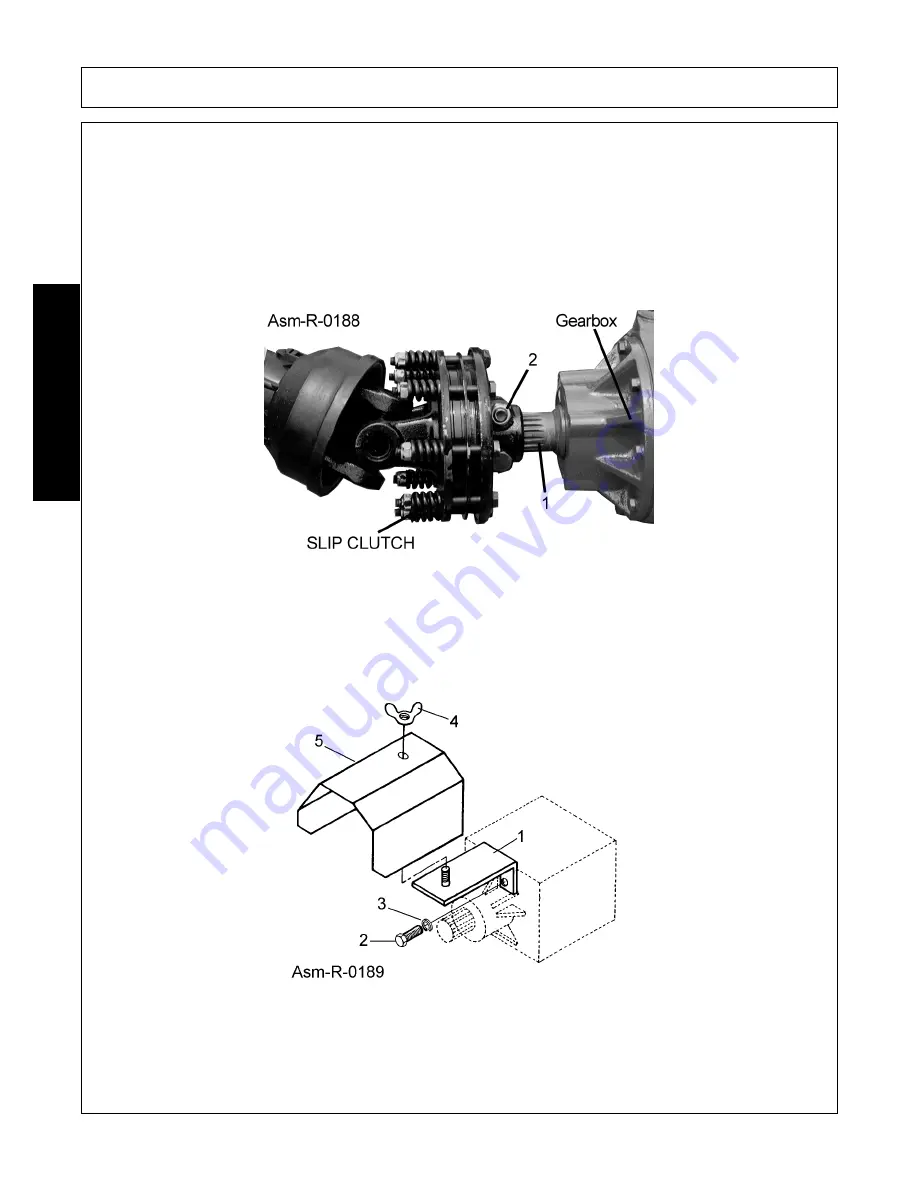

DRIVELINE ATTACHMENT

Before starting assembly, make certain that all paint, dirt, and grease are removed from gearbox shaft (1). To

ease assembly apply a light coat of grease to splines and assemble. Do not assemble a driveline without a

shield.

1. Attach the slip clutch end of the driveline to the gearbox input shaft securely. Make certain that the slip

clutch is fully onto the input shaft splines. Tighten the locknuts (2) alternately until they have reached the

proper torque. Refer to Torque Chart in Maintenance Section.

SHIELD ASSEMBLY

Remove and discard the two top bolts from the Center Gearbox. Attach Bracket (1) to the Center Gearbox with

M10 x 40 Bolts (2), and Flatwashers (3) in the same hole location. Install Shield (5) and retain with 1/2” Wing

Nut (4).

Summary of Contents for TW120

Page 9: ...Safety Section 1 1 2011 Alamo Group Inc SAFETY SECTION...

Page 28: ...SAFETY TW120 01 11 Safety Section 1 20 2011 Alamo Group Inc SAFETY Decal Description...

Page 29: ...SAFETY TW120 01 11 Safety Section 1 21 2011 Alamo Group Inc SAFETY...

Page 30: ...SAFETY TW120 01 11 Safety Section 1 22 2011 Alamo Group Inc SAFETY...

Page 31: ...SAFETY TW120 01 11 Safety Section 1 23 2011 Alamo Group Inc SAFETY...

Page 32: ...SAFETY TW120 01 11 Safety Section 1 24 2011 Alamo Group Inc SAFETY...

Page 33: ...SAFETY TW120 01 11 Safety Section 1 25 2011 Alamo Group Inc SAFETY...

Page 34: ...SAFETY TW120 01 11 Safety Section 1 26 2011 Alamo Group Inc SAFETY...

Page 35: ...SAFETY TW120 01 11 Safety Section 1 27 2011 Alamo Group Inc SAFETY...

Page 36: ...SAFETY TW120 01 11 Safety Section 1 28 2011 Alamo Group Inc SAFETY...

Page 38: ......

Page 39: ......

Page 65: ......

Page 91: ...Introduction Section 2 1 2011 Alamo Group Inc INTRODUCTION SECTION...

Page 96: ......

Page 97: ...Assembly Section 3 1 2011 Alamo Group Inc ASSEMBLY SECTION...

Page 109: ...Operation Section 4 1 2011 Alamo Group Inc OPERATION SECTION...

Page 156: ......

Page 157: ...Maintenance Section 5 1 2011 Alamo Group MAINTENANCE SECTION...

Page 160: ...MAINTENANCE TW120 01 11 Maintenance Section 5 4 2011 Alamo Group MAINTENANCE...

Page 161: ...MAINTENANCE TW120 01 11 Maintenance Section 5 5 2011 Alamo Group MAINTENANCE...

Page 174: ...MAINTENANCE TW120 01 11 Maintenance Section 5 18 2011 Alamo Group MAINTENANCE...

Page 188: ...Secci n de Seguridad 1 1 2011 Alamo Group Inc SECCI N DE SEGURIDAD...

Page 189: ......