35

DIP 16 ON and DIP 4 OFF =>

if photocells are engaged during opening, the gate stops

and the gate only closes one second after the photocells

are disengaged.

DIP 16 ON and DIP 4 ON =>

if photocells are engaged during opening, the gate continues

to open. Upon disengagement of the photocells, the gate

stops and reverses closing motion after a one second pause.

If total opening is reached (end of opening time), immediate closing is deactivated

and automatic time closing is activated (if TCA trimmer is activated and LED DL6

is on). If during closing there is a rapid movement (e.g. pedestrian) the gate will

open again for two seconds and then close once again.

DIP 16 OFF =>

immediate closing after movement in front of the photocells is deactivated.

N.B.:

Please check photocell operation at least every six months.

EDGE (SAFETY STRIP) (COM-EDGE)

If engaged during opening, reverses the motion when closing.

If engaged when closing, reverses the motion when opening.

If it remains engaged again, it performs a further reversal after 2 seconds, then performs an

additional short reversal and then gives the sensor failure or engaged alarm (N.O. contact).

If the sensor remains engaged (N.O. contact) no movement is allowed.

If not used, jump the terminals COM-EDGE.

MONITORING OF SAFETY SENSORS (A+ TEST A-)

Sensors can be monitored through the A+ TEST input and DIP 12 ON.

The monitoring consists of a functional test of the sensor run after every full gate opening.

Closing the gate is therefore permitted only if the sensors have passed the functional test

after each opening.

CAUTION:

MONITORING OF THE SENSOR INPUT CAN BE ACTIVATED WITH DIP 12 ON OR

DEACTIVATED WITH DIP 12 OFF. IN FACT, THE FUNCTIONAL TESTING OF SENSORS IS

‘POSSIBLE ONLY IF THESE DEVICES HAVE THEIR OWN POWER SUPPLY.

A MECHANICAL SENSOR CAN NOT BE MONITORED, SO DIP 12 SHOULD BE SET TO OFF.

SENSOR AUTOTEST ALARM (DIP 12 ON)

If the sensor fails the monitoring test after opening, an alarm is displayed by the blinker

lighting up. Gate closure is not allowed in this condition. Normal operation can be restored

only by repairing the sensor and pressing one of the activated controls.

STOP BUTTON (COM-STOP)

The STOP button stops the gate during any operation.

If held when the gate is fully open (or partially when using the pedestrian control) automatic

closing is temporarily deactivated (if activated by the TCA trimmer and LED DL6 on). It is

therefore necessary to use a new command to make it close.

The automatic closing function is reactivated on the next cycle (if activated by the TCA

trimmer and LED DL6 on).

POWER SENSOR ALARM

The T2 PREMIER 24V control panel has automatic sensors that make the movement of the

gate reverse in case of impact against objects or persons in accordance with the current

EN standards (always use the right tool to ensure compliance with the values imposed by

the standard), without special adjustments on the control panel, as it operates using special

internal software. If the power sensor is used in opening or closing (only in high-speed) and

then again, in the opposite direction, the gate stops and then reverses for 1 second.

The alarm status will be displayed by the blinker which will remain active for one minute,

during which time you can restore gate operation by pressing any command button.

FUNCTIONING IN DEAD MAN MODE WHEN THE SAFETY DEVICES ARE FAILING

If the safety edge fails or remains engaged for more than 5 seconds, or if photocell fails

or remain engaded for more than 60 seconds, the open, close, k button and pedestrian

commands will work only in dead man mode.

The signal that this mode has been activated is given by the blinking of the programming led.

With the blinking of the programming led, the opening and closing operation are allowed

only with the command button pressed and held. The radio commands and that of automatic

closing, will be excluded, since their use in this mode, is not allowed by the norms.

Once the failing safety device is repaired, in automatic after 1 second, all standard

commands that were selected, such as step by step, automatic mode, radio commands and

automatic closing start functioning again.

Note 1:

during this functioning in dead man mode, in case of damage to the safety strips

(or photocells) the photocells (or safety strips) still work by interrupting the operation

in progress.

Note 2:

the stop command is not to be considered a safety command that can be bypassed

in this mode. Therefore, when pressed or damaged, it will not allow any movement

of the gate.

The dead-man operation is only an emergency operation which must be activated

for a very short period and with the complete installation at sight so to have a

secure and safe control of the system. As soon as possible however, the failing

safety devices must be repaired and activated.

BLINKER

N.B.:

This control panel can power ONLY BLINKERS ON A (ACG7061) CIRCUIT with lamps

up to 24V and 20W.

PRE-BLINKING

DIP 5 - OFF => the motor and blinker begin simultaneously.

DIP 5 - ON => the blinker begins 3 seconds before the motor.

GATE OPEN WARNING LIGHT (COM-SIGNAL)

Signals when the gate is open, partially open or not closed completely. Turns off only when

the gate is completely closed. This signal is active during programming.

N.B.:

Max 3 W. If

push buttons or lamps are in excess, the control panel processes will be endangered and

possibly halt operation.

OPERATION AFTER A BLACK-OUT (WITHOUT BATTERIES)

When the power supply comes back the DL1 led turns on and remains on for all the time

the gate stays open. The led will turn off only once the gate is completely closed. It is

recommended to fully open the gate. Let the gate close by itself or with automatic closing,

or wait until the blinker stops flashing before commanding it to close.

This will allow the gate to realign. If, motors were released and moved from the normal

position when closed during the blackout, the first movement after power returns must be

complete.

If the black out occurs when the gate is still moving or when the gate is open and the first

command sent after the black out is a closing command, the closing of the gate will be

carried out with a total delay between the two gate leaves. Therefore, first the leaf M2 will

close completely; once it is off, M1 will start closing. This separate movement of the two

gate leaves is done to avoid their incorrect overlapping.

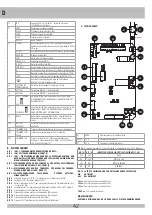

TECHNICAL SPECIFICATIONS

- Temperature range

0 ÷ 55 °C

- Humidity

<95 % without condensation

- Voltage

230 V~ ± 10% (120 V 60 Hz upon request)

- Frequency

50/60 Hz

- Battery power

20-24 Vdc

- Transformer Power

130VA - primary 230 Vac - secondary 18 Vac

- Maximum absorption

50 mA

- Network Micro-switches

100ms

- Maximum power gate open indicator 24 Vdc 3 W (equivalent to one 3 W or 5 LED light

bulb with resistor in series at 2,2 K

Ω

)

- Maximum blinker power

24 Vdc 20 W

- Power available for photocells and accessories 1A ± 15%

- Power available for radio connector 200 mA

RADIO SPECIFICATIONS (model T2 PREMIER 24V-CRX)

- Receiving Frequency

433,92 MHz

- Impedance

52

Ω

- Sensitivity

>2,24 µV

- Pick-up time

300 ms

- Drop time

300 ms

- All inputs must be used as clean contacts because the power is generated internally

(secure power) to the board and is set up to ensure compliance with double or reinforced

insulation with regard to dangerous voltage.

- Any external circuits connected to the outputs of the control panel must be made in such

a manner as to ensure compliance with double or reinforced insulation with regard to

dangerous voltage.

- All inputs are controlled by a programmed integrated circuit that performs a self check

every time it starts operating.

TROUBLE SHOOTING

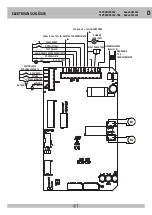

After having carried out all connections, by carefully following the layout and having

positioned the gate in intermediate position, check the correct ignition of red LEDS DL7,

DL8 and DL9

In case of no ignition of the LEDS, always with gate in intermediate position, check the

following and replace any faulty components.

DL7 switched OFF Faulty photocells

DL8 switched OFF

Faulty safety edge (In case the edge is not connected, carry out

jumper between COM and EDGE)

DL9 switched OFF

Stop button malfunction (if Stop is not connected, perform the jump

between COM and STOP).

During functioning with personnel present, with DIP 1 at ON, check that during opening of

M1 and M2 the green DL2 and DL4 LEDS switch on and that during closing of M1 and M2

the red DL3 and DL5 LEDS switch on.

Or else, reverse the wires of the motor.

G

B