33

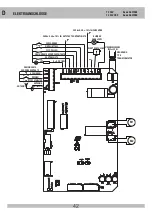

B - SETTINGS

DIP 1

(ON) - MOTOR ROTATION DIRECTION CONTROL (POINT C)

DIP 2

(ON) - TIMER (POINT D)

DIP 3

(ON) - ACTIVATES DOOR RELEASE DURING PHASES OF SLOWDOWN AND

TOTAL OPENING AND CLOSING (AS PER THE IMPACT TESTS OF EN12453)

DIP 1-2

MEMORIZATION/CANCELLATION OF RADIO CONTROL CODES FOR TOTAL

OPENING (ONLY MODEL CRX) (POINT E)

DIP 1-3

MEMORIZATION/CANCELLATION OF RADIO CONTROL CODES FOR

PEDESTRIAN OPENING (ONLY MODEL CRX) (POINT F)

DIP 2-1

MICRO-SWITCH CONTROLLER FOR PEDESTRIAN OPENING TIMER

DIP 4

Photocells always active (OFF) - Photocells active only during closing (ON)

DIP 5

Pre-blinking (ON) - Normal blinking (OFF)

DIP 6

Single pulse command (K BUTT) and step-by-step radio receiver (OFF) - automatic

(ON)

DIP 7

Power sensor operation (ON-activated) time operation (OFF-activated).

DIP 8

Electric lock activation (ON-activated)

DIP 9

Electric lock pulse release (ON-activated)

DIP 10

Electric lock pulse engagement (ON-activated)

DIP 11

Easy release activation (ON-activated)

DIP 12

Sensor TEST activation (ON-activated).

DIP 13

Selection of 1 or 2 motor operation (default OFF 2 motors)

DIP 14

KING 24 - ON

DIP 15

KING 24 - OFF

DIP 16

IMMEDIATE CLOSING AFTER PASSING IN FRONT OF PHOTOCELLS

ON ACTIVATED

OFF DEACTIVATED

JP1 =>

Check that the jumper is inserted!

JP2 =>

Check that the jumper is inserted!

JP3 =>

Check that the jumper is inserted!

PROG =>

S3 Programming button

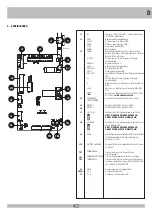

ADJUSTMENTS

ATTENTION: PUT DIP 3 IN THE ON MODE ONLY AFTER HAVING CARRIED OUT ALL THE

PROGRAMMING PROCEDURES.

NOTE: WITH DIP 3 (ON) BRIEF GATE REVERSAL AFTER IMPACT IS ACTIVATED.

THIS BRIEF GATE REVERSAL PERMITS STATIC FORCE TO BE REDUCED TO ZERO

WITHIN 5 SECONDS AS PER STANDARD EN12453 POINT A.2.2 (ACCEPTABLE STATIC

FORCE), THEREBY COMPLYING WITH THE IMPACT TESTS ALSO OUTLINED BY

EN12453).

IF COMPLIANCE WITH THE AFOREMENTIONED STANDARD IS UNNECESSARY, SIMPLY

POSITION DIP 3 TO OFF. IN THIS CASE THE GATES STOP WITHOUT REVERSING.

RUN TRIMMER (TR1) high-speed electronic regulator

This trimmer permits motor speed adjustment (the default setting is maximum speed).

Adjustment of the automation is useful for compliance with European impact standards.

LOW-SPEED TRIMMER (TR2) Electronic slow speed approach control

The slow speed control is performed by adjusting the LOW- SPEED TRIMMER which changes

the voltage output across the motor(s) (turning it clockwise increases the speed). Adjustment

is performed to determine the correct speed at the end of opening and closing according to

the gate or when there is friction that might cause the system to function poorly.

AUTOMATIC CLOSING TRIMMER - TCA (TR3) TOTAL OR PEDESTRIAN default NOT

ACTIVATED and LED DL6 OFF (TRIMMER FULLY ROTATED COUNTERCLOCKWISE)

This trimmer makes it possible to adjust the time for total or pedestrian automatic closing.

Only with gate completely (total) or partially (pedestrian) open and LED DL6 on (trimmer

rotated clockwise).

The pause time can be adjusted from a minimum of two seconds up to a maximum of two

minutes.

LED SIGNALS

DL1 program activated (red)

DL2 gate opening M2 (green)

DL3 gate closing M2 (red)

DL4 gate opening M1 (green)

DL5 gate closing M1 (red)

DL6 automatic closing indicator (red)

DL7 photocell contact (NC) (red)

DL8 sensor contact (NC) (red)

DL9 STOP button (NC) (red)

DL10 radio code program (green)

FUSES

Fuse 1 T 8A

MOTOR PROTECTION FUSE

F1 T 2A

TRANSFORMER PROTECTION FUSE (on the outside of the T2 24V board)

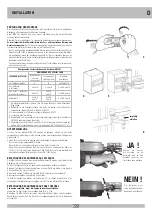

C - MOTOR ROTATIONAL DIRECTION CONTROL

1 - Set DIP 1 to ON => LED DL1 starts flashing.

2 - Press and hold the PROG button. (movement is now manually controlled - open-stop-

close-stop-open - etc.) => GREEN LEDS DL2 and DL4 are lit and the gate panels open

with a fixed lag of 2 sec. If they close instead of open, release the button and reverse the

two wires on the motor used.

3 - After opening release the PROG button and calibrate the mechanical opening stops (on

the operator).

4 - Press and hold the PROG button => RED LEDs DL3 and DL5 turn on and the gate panels

close with a time lag of 2 sec.

5 - Continue to hold the PROG button until the gate is completely closed.

6 - Leave the two doors completely closed to set the timer.

7 - Reset DIP1 to OFF => LED DL1 turns off, signaling exit from control.

N.B.: During this check the stop, the photocells and the sensors are not active.

D - SETTING THE TIMER FOR 2 MOTORS (#) WITH POWER SENSOR

ACTIVATED (DIP 7 ON)

WHILE SETTING THE TIMER THE POWER SENSOR IS CONTINUOUSLY ACTIVATED.

1 - The gate must be completely closed.

2 - Set DIP 2 to ON => LED DL1 will blink rapidly.

3 - Press the PROG button. => M1 opens.

4 - When the mechanical opening stop is reached, the AUTOMATIC POWER SENSOR stops

M1 (memorizing the time and the power) => At the same time M2 is triggered to open.

5 - When the mechanical opening stop is reached, the AUTOMATIC POWER SENSOR stops

M2 (memorizing the time and the power).

6 - Press the PROG button. => M2 closes.

7 - Press the PROG button. => M1 closes and sets the lag time between M2 and M1. At

the same time LED DL1 stops flashing indicating exit from the programming procedure.

Safety and other gate commands now operate normally (inversions, stop, alarms, etc.).

8 - The gate panels will close in high-speed mode (depending on how you set the RUN

trimmer) and near total closure in the slow mode (depending on how you set the LOW-

SPEED trimmer).

9 - Upon closing the power sensors stop the gate.

10 - AFTER PROGRAMMING RESET DIP 2 TO OFF.

D - SETTING THE TIME FOR ONE MOTOR (M1) (#) WITH POWER

SENSOR ACTIVATED (DIP 7 ON)

CAUTION: FOR ONE MOTOR CONTROL DIP 13 MUST BE POSITIONED TO ON; DURING

PROGRAMMING THE POWER SENSOR IS CONTINUOUSLY ACTIVE.

The gate must be completely closed.

1 - Set DIP 2 to ON => LED DL1 will blink rapidly.

2 - Press the PROG button. => M1 opens.

When the mechanical opening stop is reached, the AUTOMATIC POWER SENSOR stops

M1 (memorizing the time and the power).

3 - Press the PROG button. => M1 closes.

At the same time LED DL1 stops flashing indicating exit from programming. Safety and

other gate commands now operate normally (inversions, stop, alarms, etc.).

Upon closing the power sensor stops the gate.

4 -

AFTER PROGRAMMING RESET DIP 2 TO OFF.

(#) DURING PROGRAMMING THE SAFETY DEVICES ARE ACTIVE AND STOP THE

PROGRAMMING PROCEDURE (LED DL1 FROM FLASHING BECOMES CONSTANT).

TO REPEAT PROGRAMMING SET DIP 2 TO OFF, CLOSE THE GATE USING THE

PROCEDURE “MOTOR ROTATIONAL DIRECTION CONTROL” AND REPEAT THE

DESIRED PROGRAMMING PROCEDURE.

G

B