33

3

PRE-INSTALLATION CHECK

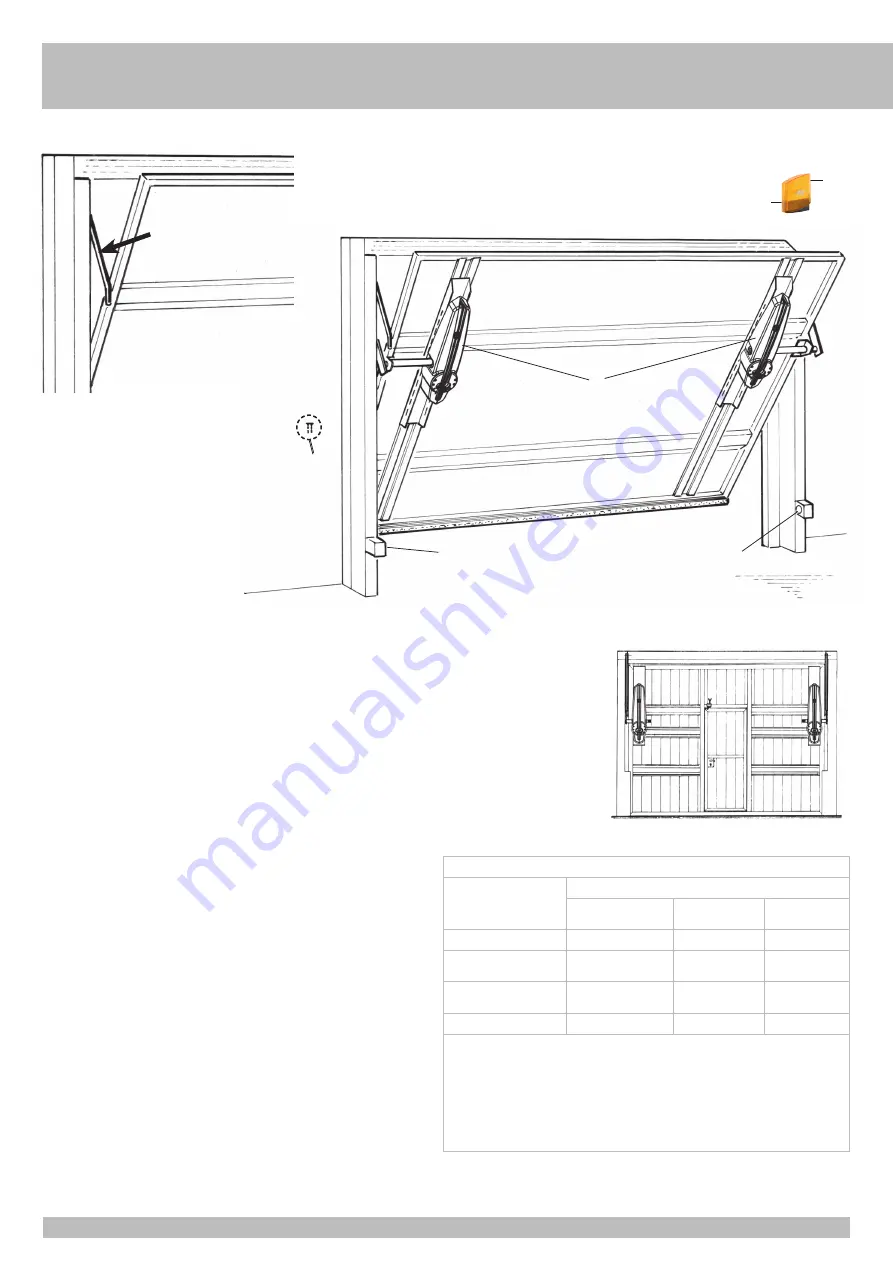

For doors with a total width up to 6 m, maximum height 2,5 m or a total surface area of 12 square metres and door lever’s length

with maximum length 83 cm, 2 BOSS (MASTER A SLAVE AA40845) device should be used; mounted as shown in Fig.

3, with a PAIR OF STRAIGHT LEVERS code ACG8720 (or a PAIR OF CURVED LEVERS code ACG8722), the accessories for LATERAL

TRANSMISSION for 2 operators cod. ACG8715 and 2 SHORT MOUNTING PLATE codes ACG8189 or 2 LONG MOUNTING PLATE codes

ACG8188.

- Check that the available space between the moving frame of the door and external frame with counterweights exceeds 15 mm.

If so, the STRAIGHT LEVERS can be mounted. Otherwise, mount the CURVED LEVERS if the distance is less than 15 mm, making

sure to remain within the assembly parameters described in Fig. 4.

- Check that the up-and-over door slip bearings are not blocked or obstructed and that the counterweight fastening cables are

in correct working order.

- Remove, if present, the manual closing lever connected to the locking device.

N.B.

It is obligatory to uniform the characteristics of the door to the standards and laws in

force. The door can be automatized only if in a good state and if in accordance with

EN 12604 standard.

No trapping points must be generated (for example between horizontally pivoted open door

and wall).

G

B

5

5

4

1

1 -

1 BOSS 1 BOSS SLAVE

2 - Aerial

3 - Blinker

4 -

BLOCK Wi-Fi key selector

5 -

Photoelectric cells (internal)

2

3

The door lever’s length

cannot exceed the 83 cm

BOSS MASTER

BOSS MASTER

BOSS SLAVE

BOSS SLAVE

Parts to install according to EN 12453 standard

COMMAND TYPE

USE OF THE SHUTTER

Skilled persons

(out of public area*)

Skilled persons

(public area)

Not skilled

persons

Hold-to-run operation

A

B

Not possible

Impulsive - in sight

(e.g. push-button)

C or E

C or E

C and D, or E

impulsive - out of sight

(e.g. remote)

C or E

C and D, or E

C and D, or E

automatic

C and D, or E

C and D, or E

C and D, or E

* a typical example are those doors which do not have access to any public way

A: Hold-to-run operation made by push-button ex: code ACG2013

B: Hold-to-run operation made by key selector ex: code ACG1010

C: Adjustable power of the motor or photocells to respect impact forces as indicated in Annex

A

D: Safety strips and/or other additional devices to reduce the probability of contact with the

door.

E: Devices installed in such a way that a person can not be touched by the door.