29

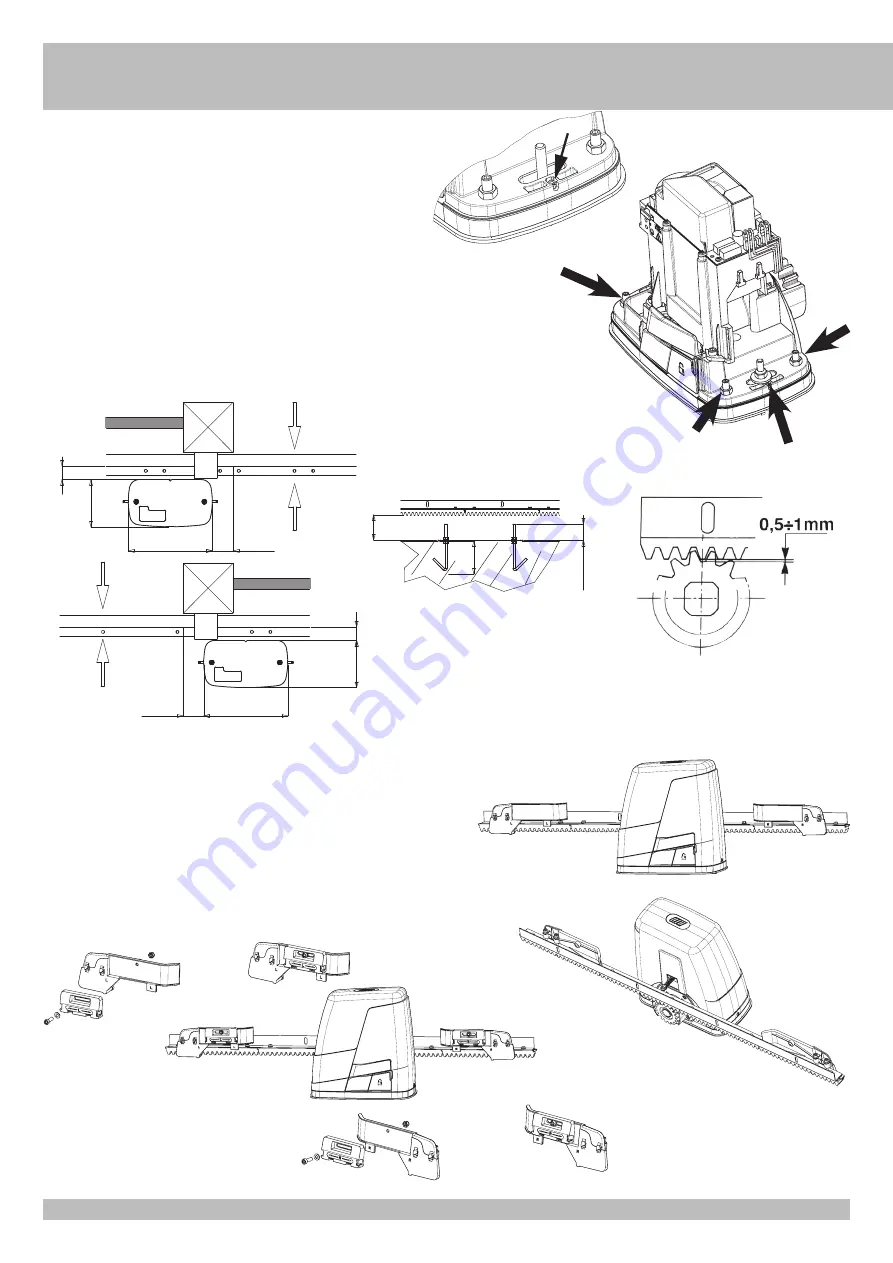

MOTOR AND RACK FITTING

Operator K400 comes with a base plate for vertical adjustment.

Such adjustment proves to be useful to set a 1mm clearance between the drive gear

and the rack. Insert the two 4MA self-locking nuts which are needed to fix the cover of

the K400 operator before securing the operator to its base plate using the nuts and flat

washers 8MA 8x26 provided (see Pict. 5).

The base plate features two hooks that can be used to secure the system on the ground

(Fig. 6).

The rack shall be fitted over the motor support, at a certain distance from it.

Its height can be adjusted thanks to the holes In the rack.

The towing gear must have at least 1 mm of backlash compared to the rack (Fig. 7).

The height is adjusted to prevent the gate from resting on the driving gear of the K as

it moves.

To fix the rack on the gate, drill some Ø 5 mm holes and thread them using an M6

screw tap.

The driving gear needs some 1 mm clearance from the rack.

LIMIT SWITCH FITTING

In order to determine the travel of the moving part, place two cams at the ends

of the rack

(Fig. 8, 9).

Move the cams on the rack teeth to adjust their opening and closing travel.

To fix the cams to the rack, tighten the screws issued.

N.B: In addition to the electric stop cams mentioned above, you must also install strong

mechanical stops preventing the gate from sliding out of the top guides.

Measurements in mm

Measurements in mm

5

Measurements in mm

G

B

7

8

0÷50

50

÷

54

85

46

46

159

159

100

0÷50

284

284

9

K400 FCM

K400 FCE

6