Page 39 / 66

The support table 3 positions allow the splitter to work on logs of 58cm, 77cm or 106cm in length.

Insert the support table in the position nearest to the log length, and secure the support table with the

locking hooks.

When cutting up limbs and large sections, do not cut sections any longer than 100cm.

6. Apply a thin coat of grease to the surfaces of the ram before operation will lengthen the durability

of the ram.

7. Route the power cord.

Route the cord from the power source to the splitter in a way that safeguards against tripping on the

cord, or the cord becoming damaged during the work session.

Protect the power cord from impacts, pulling or corrosive materials.

8. Open the Air Bleed.

Loosen the oil tank cover a few turns whenever the splitter is being used.

Retighten this cover when you finished.

9. While operating under extremely low temperature, let the log splitter run under no load for

15minutes to preheat the hydraulic oil

10. Reminder: The log splitter is strictly designed for one-man operation. Never allow more than one

person approach and work on the machine at the same time.

5.4- Placing the log on the splitter

Prepare the wood to be split by pre-cutting it to the maximum cutting capacity of the splitter and

make sure that the wood is cut straight.

Put the wood on the splitter so as not to endanger you (e.g. tripping hazard).

5.4.1- For 042101 - log splitter 6T

Set the log firmly on the log retaining plates and

work table (4).

Make sure the log will not twist, rock or slip while

being split.

Do not force the blade by splitting the log on the

upper part. This will break the blade or damage

the machine.

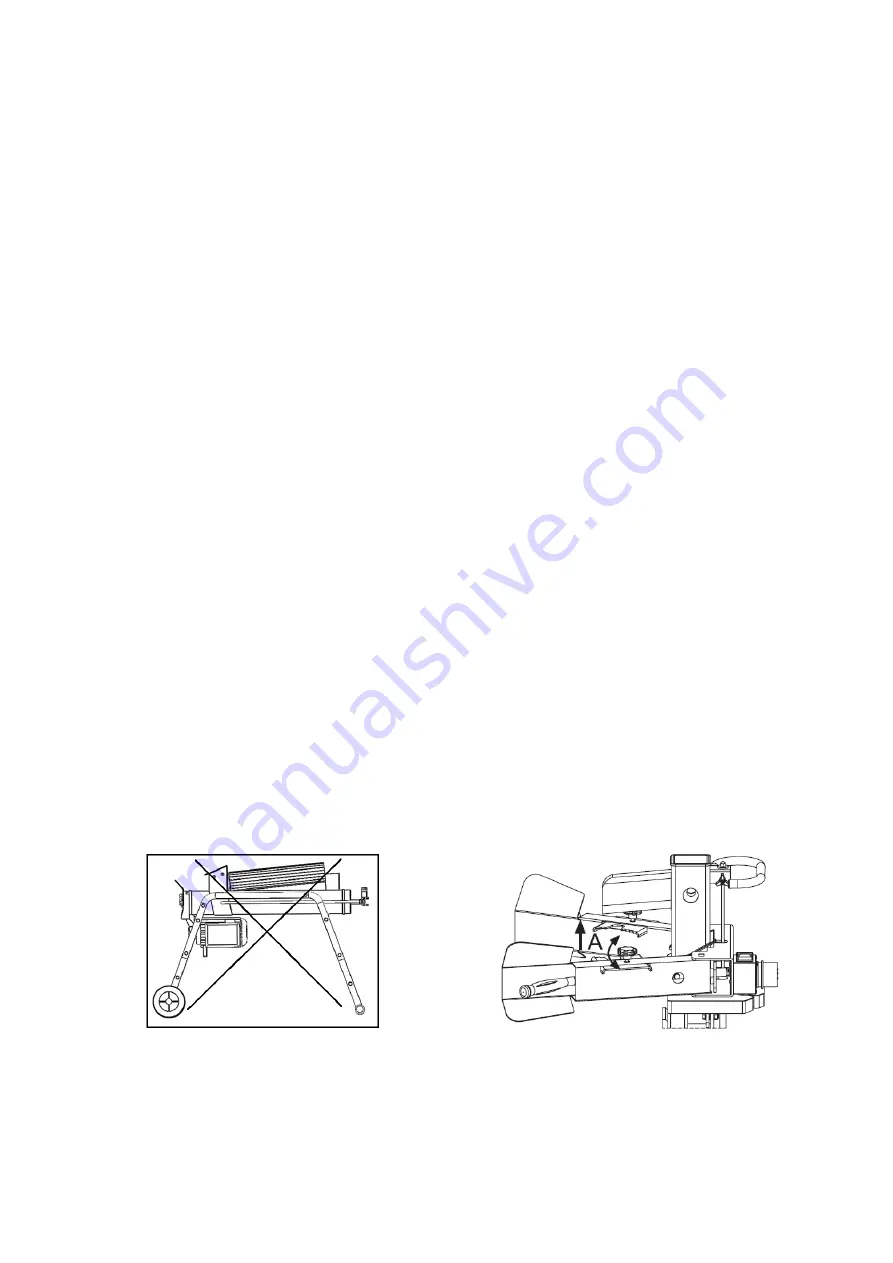

5.4.2- For 042111 - log splitter 7T

a) Place the log vertically and sitting flat onto the

support table (14).

Be sure the wedge and support table will contact the

log squarely on the ends.

Never attempt to split a log at an angle.

b) Adjust the Log Holders Claws (A) according to

the diameter of the log to obtain most comfortable

Control Levers angle (Fig.15).

c) Hold the log with clamping brackets closely in the

control lever guards (Fig.19).

Never open clamping brackets while ram is moving

(Fig.19)

Fig.11

Fig.12