Page

30

/

59

- free of obstacles

- sufficiently well lit

- Do not operate the machine in the direct vicinity of gas or petrol pipes or containers, or any other

easily inflammable or explosive materials.

4.4- Electrical requirements

With a 230V~ 50Hz motor, the log splitter should be connected to standard 230V

10% (50Hz

1Hz).

The mains connection should be fused for a maximum of 16A.

The electrical supply must be fitted with protection devices of under-voltage, over-voltage, and

over-current as well as a residual current device (RCD), which maximum residual current rated at

0.03A.

Electrical connection rubber cables must comply with EN60245 which are always marked with

H07RN, and with cross section greater than 1.5mm

2

.

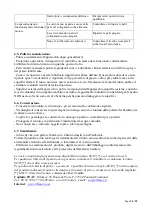

Wiring and hydraulic diagrams:

Electrical diagram

Hydraulic diagram

4.5- Bleed the air

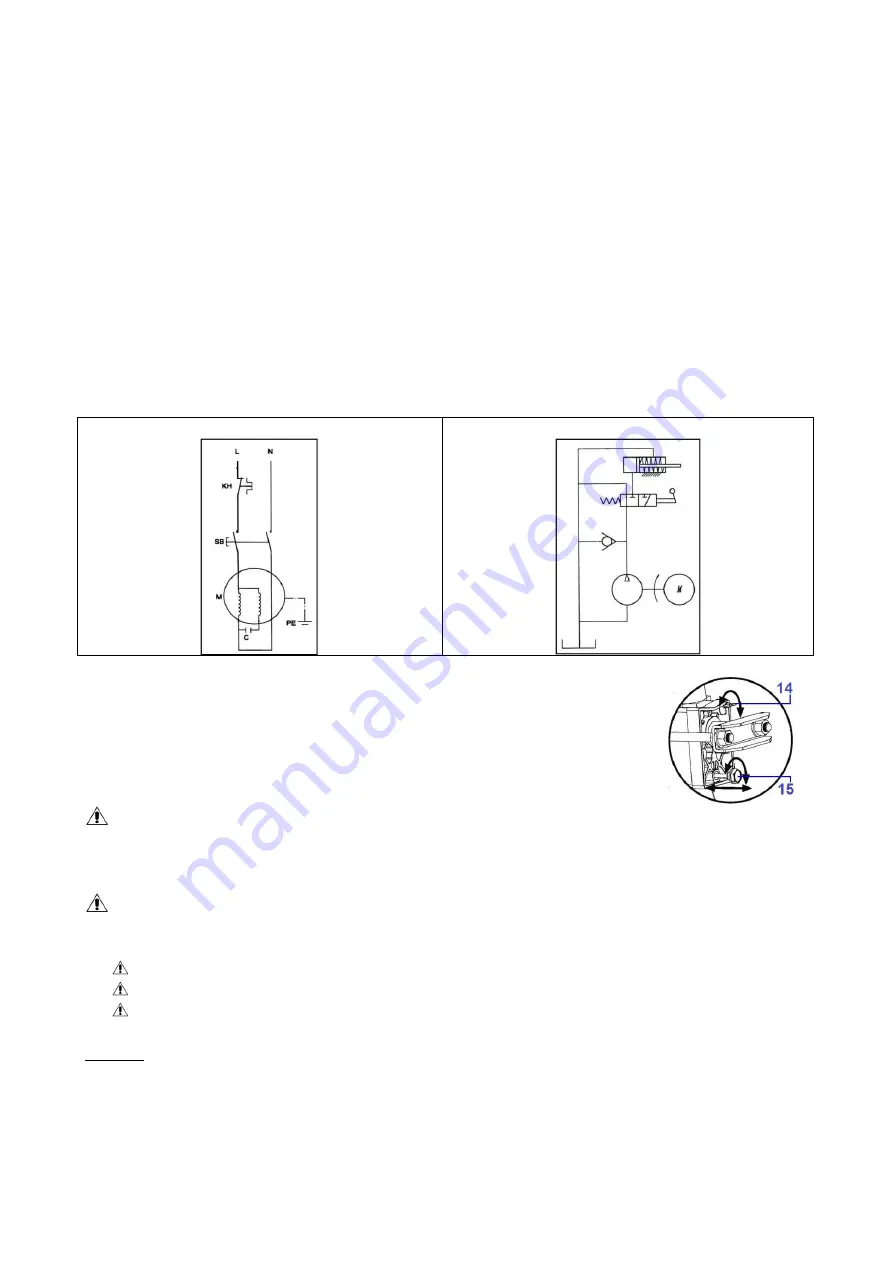

- Loosen the air bleed valve (14) a few turns whenever the splitter is being used.

- Keep air bleed valve (14) opened during operation.

- Retighten this air bleed valve (14) once you finished.

Failure to loosen the bleed screw will keep the sealed air in the hydraulic system.

The air being compressed and then decompressed, such continuous air compression and

decompression will blow out the seals of the hydraulic system and cause permanent damage to the log

splitter.

Before moving or transporting the log splitter, close the bleed screw to avoid any spillage.

4.6- Moving the Log Splitter

Before moving or transporting the log splitter, unplug it from the mains power supply.

Make sure the oil dipstick cap (3) is securely tightened

Make sure the oil drain screw is securely tightened.

By hand

WARNING: The log splitter is very heavy, do NOT move by hand if you are not physically strong

enough, as a falling or tripping machine may cause considerable damage and severe injury!!

The log splitter is equipped with 2 wheels for minor moving

To move the log splitter to the work area, grip the handle to tilt the log splitter slightly.

The wheels are not intended to transport or tow the log splitter over long distance.